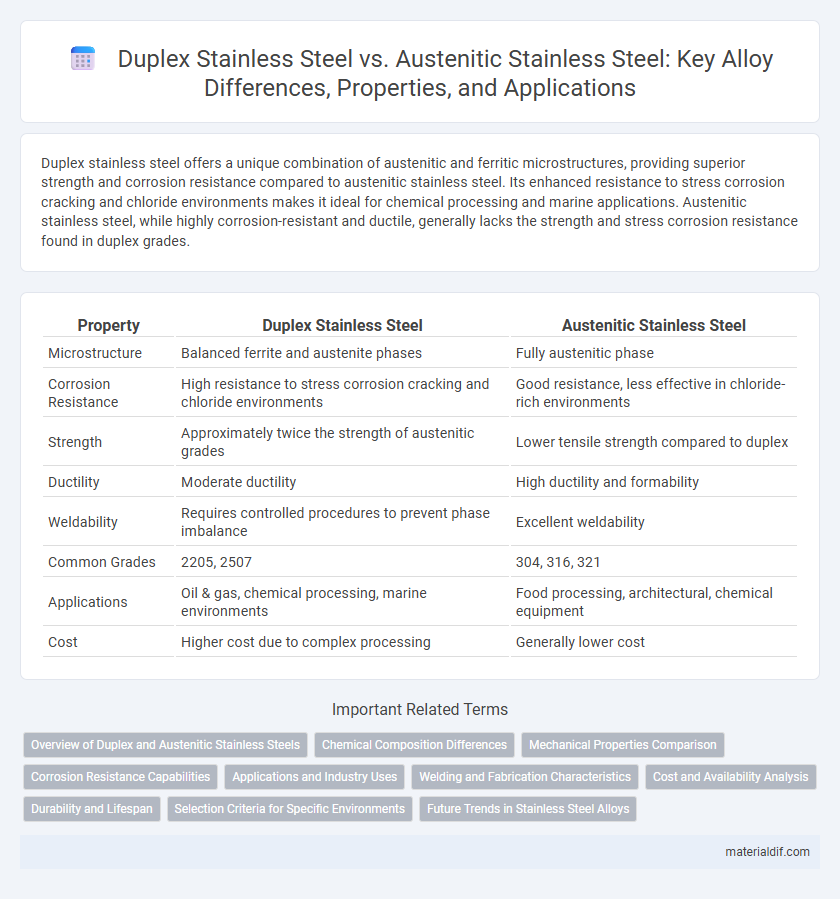

Duplex stainless steel offers a unique combination of austenitic and ferritic microstructures, providing superior strength and corrosion resistance compared to austenitic stainless steel. Its enhanced resistance to stress corrosion cracking and chloride environments makes it ideal for chemical processing and marine applications. Austenitic stainless steel, while highly corrosion-resistant and ductile, generally lacks the strength and stress corrosion resistance found in duplex grades.

Table of Comparison

| Property | Duplex Stainless Steel | Austenitic Stainless Steel |

|---|---|---|

| Microstructure | Balanced ferrite and austenite phases | Fully austenitic phase |

| Corrosion Resistance | High resistance to stress corrosion cracking and chloride environments | Good resistance, less effective in chloride-rich environments |

| Strength | Approximately twice the strength of austenitic grades | Lower tensile strength compared to duplex |

| Ductility | Moderate ductility | High ductility and formability |

| Weldability | Requires controlled procedures to prevent phase imbalance | Excellent weldability |

| Common Grades | 2205, 2507 | 304, 316, 321 |

| Applications | Oil & gas, chemical processing, marine environments | Food processing, architectural, chemical equipment |

| Cost | Higher cost due to complex processing | Generally lower cost |

Overview of Duplex and Austenitic Stainless Steels

Duplex stainless steel combines austenitic and ferritic microstructures, offering enhanced strength, corrosion resistance, and stress corrosion cracking resistance compared to traditional austenitic stainless steel. Austenitic stainless steel, primarily composed of iron, chromium, and nickel, provides excellent corrosion resistance and high ductility, making it suitable for a wide range of industrial applications. Duplex grades typically exhibit higher tensile strength and better chloride stress corrosion cracking resistance, making them preferred for chemical processing and marine environments.

Chemical Composition Differences

Duplex stainless steel contains a balanced microstructure of approximately 50% ferrite and 50% austenite, enriched with higher chromium (18-28%), molybdenum (up to 5%), and nitrogen, enhancing its corrosion resistance and strength. Austenitic stainless steel primarily consists of 16-26% chromium and 6-22% nickel, with minimal molybdenum and nitrogen content, resulting in excellent formability and toughness. The chemical composition differences, specifically the added nitrogen and molybdenum in duplex grades, significantly improve resistance to stress corrosion cracking and pitting compared to austenitic stainless steels.

Mechanical Properties Comparison

Duplex stainless steel exhibits superior mechanical properties compared to austenitic stainless steel, including higher tensile strength typically ranging from 620 to 880 MPa versus 485 MPa for standard 304 austenitic grades. Duplex grades offer better yield strength, often around 450 MPa, almost double that of austenitic stainless steels, leading to enhanced resistance against deformation under load. The improved strength of duplex stainless steel allows for thinner sections in structural applications while maintaining durability and toughness.

Corrosion Resistance Capabilities

Duplex stainless steel offers superior corrosion resistance compared to austenitic stainless steel due to its balanced microstructure of approximately 50% ferrite and 50% austenite, which enhances resistance to stress corrosion cracking and chloride-induced pitting. Its higher chromium, molybdenum, and nitrogen content provides increased protection against localized corrosion in harsh environments like seawater or chemical processing. Austenitic stainless steel, while resistant to general corrosion, is more susceptible to chloride stress corrosion cracking and typically exhibits lower strength in aggressive settings.

Applications and Industry Uses

Duplex stainless steel is widely used in chemical processing, oil and gas, and marine industries due to its superior corrosion resistance and high strength, making it ideal for harsh environments. Austenitic stainless steel finds extensive application in food processing, pharmaceuticals, and architectural projects where excellent formability and resistance to oxidation are essential. Both alloys serve critical roles in industries demanding durability and corrosion performance, with duplex offering enhanced robustness in chloride-rich conditions.

Welding and Fabrication Characteristics

Duplex stainless steel offers superior weldability compared to austenitic stainless steel due to its balanced microstructure, which reduces the risk of hot cracking and enhances strength in welded joints. Fabrication of duplex alloys requires careful control of heat input and interpass temperature to maintain corrosion resistance and prevent sigma phase formation, while austenitic stainless steel exhibits greater ductility, allowing easier forming and shaping but higher susceptibility to weld-induced distortion. Welding duplex stainless steel typically involves using low heat input processes and matching filler metals to preserve its duplex nature, whereas austenitic stainless steel welding tolerates a broader range of techniques but demands post-weld heat treatment for optimal performance in certain grades.

Cost and Availability Analysis

Duplex stainless steel generally costs more than austenitic stainless steel due to its higher alloy content, including chromium, molybdenum, and nitrogen, which enhance corrosion resistance and strength. Availability for austenitic stainless steel, such as grades 304 and 316, is broader and more consistent worldwide, driven by widespread demand across industries. Duplex stainless steel, while less common, is increasingly available as its benefits justify higher upfront costs in applications requiring durability and lower maintenance expenses over time.

Durability and Lifespan

Duplex stainless steel offers superior durability compared to austenitic stainless steel due to its balanced microstructure of austenite and ferrite, enhancing resistance to stress corrosion cracking and chloride-induced corrosion. Its unique composition delivers a longer lifespan in harsh environments, making it ideal for chemical processing and marine applications. Austenitic stainless steel, while corrosion-resistant, typically exhibits lower strength and durability under high-stress conditions, limiting its service life relative to duplex grades.

Selection Criteria for Specific Environments

Duplex Stainless Steel offers superior corrosion resistance and higher strength compared to Austenitic Stainless Steel, making it ideal for harsh environments such as seawater and chemical processing. Austenitic Stainless Steel excels in applications requiring exceptional formability and weldability, especially in mildly corrosive or high-temperature settings. Selecting between these alloys depends on factors like chloride exposure, mechanical stress, temperature range, and cost considerations specific to the industrial environment.

Future Trends in Stainless Steel Alloys

Future trends in stainless steel alloys emphasize the growing adoption of duplex stainless steel due to its superior strength, corrosion resistance, and cost efficiency compared to austenitic stainless steel. Innovations in alloy composition aim to enhance duplex grades' thermal stability and weldability, addressing limitations traditionally associated with austenitic variants. Increased demand in industries such as chemical processing, oil and gas, and marine engineering drives research toward balancing mechanical performance with environmental sustainability in next-generation stainless steel alloys.

Duplex Stainless Steel vs Austenitic Stainless Steel Infographic

materialdif.com

materialdif.com