Nickel alloy offers superior corrosion resistance and strength at high temperatures compared to Monel, making it ideal for harsh chemical environments. Monel, primarily composed of nickel and copper, excels in marine applications due to its excellent resistance to seawater corrosion. Both materials provide robust performance, but the choice depends on specific environmental conditions and mechanical requirements.

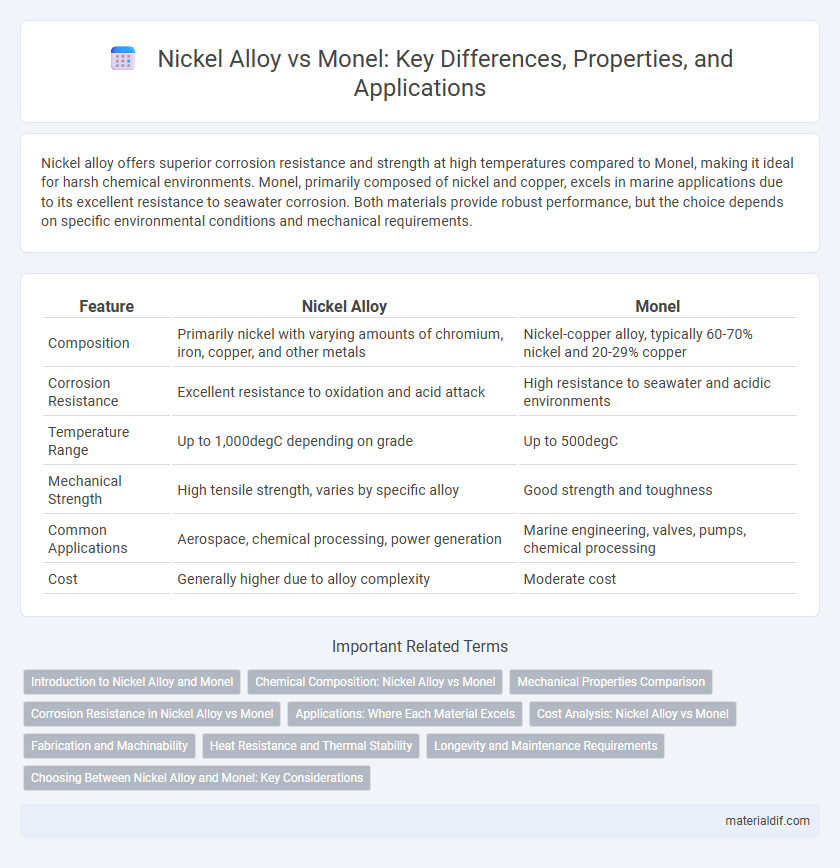

Table of Comparison

| Feature | Nickel Alloy | Monel |

|---|---|---|

| Composition | Primarily nickel with varying amounts of chromium, iron, copper, and other metals | Nickel-copper alloy, typically 60-70% nickel and 20-29% copper |

| Corrosion Resistance | Excellent resistance to oxidation and acid attack | High resistance to seawater and acidic environments |

| Temperature Range | Up to 1,000degC depending on grade | Up to 500degC |

| Mechanical Strength | High tensile strength, varies by specific alloy | Good strength and toughness |

| Common Applications | Aerospace, chemical processing, power generation | Marine engineering, valves, pumps, chemical processing |

| Cost | Generally higher due to alloy complexity | Moderate cost |

Introduction to Nickel Alloy and Monel

Nickel alloy is a versatile category of metal alloys primarily composed of nickel combined with elements such as chromium, iron, and molybdenum to enhance strength, corrosion resistance, and heat tolerance. Monel, a specific type of nickel alloy, consists predominantly of nickel (around 65-70%) and copper, offering superior corrosion resistance in marine and chemical environments. The key difference lies in their composition and applications: nickel alloys cover a broader range of grades for high-temperature and industrial use, while Monel is specialized for extreme corrosion resistance and durability in harsh conditions.

Chemical Composition: Nickel Alloy vs Monel

Nickel alloys typically contain a high percentage of nickel, often ranging from 50% to 95%, combined with elements like chromium, iron, molybdenum, and copper to enhance corrosion resistance and mechanical properties. Monel, a specific type of nickel alloy, consists primarily of 65-70% nickel and 20-29% copper, with small amounts of iron, manganese, carbon, and silicon, offering superior resistance to seawater corrosion and acid environments. The distinctive copper content in Monel differentiates it from other nickel alloys, influencing its strength and corrosion resistance characteristics.

Mechanical Properties Comparison

Nickel alloys exhibit higher tensile strength and better corrosion resistance than Monel, making them suitable for extreme environments. Monel offers superior toughness and excellent impact resistance, especially at low temperatures, due to its high nickel and copper content. Mechanical performance varies with composition, where nickel alloys typically outperform in high-temperature stability, while Monel excels in resistance to seawater corrosion and fatigue.

Corrosion Resistance in Nickel Alloy vs Monel

Nickel alloys exhibit superior corrosion resistance in highly oxidizing environments due to their high nickel content and specialized alloying elements like molybdenum and chromium, which enhance chemical stability. Monel, a specific nickel-copper alloy, provides excellent resistance to seawater and alkaline environments, making it highly effective in marine applications but generally less versatile than broader nickel alloys in acidic or high-temperature conditions. The choice between nickel alloy and Monel depends on the specific corrosive environment, where nickel alloys offer broader protection against acidic corrosion while Monel excels in chloride-rich or marine environments.

Applications: Where Each Material Excels

Nickel alloys demonstrate superior performance in high-temperature environments, making them ideal for aerospace engines, chemical processing, and power generation industries due to their exceptional corrosion resistance and mechanical strength. Monel excels in marine and chemical applications where resistance to seawater corrosion and acidic conditions is critical, commonly used in marine hardware, valves, and pumps. While nickel alloys offer versatility across extreme temperature and corrosive scenarios, Monel's niche strength lies in its robustness against harsh saline and acidic environments.

Cost Analysis: Nickel Alloy vs Monel

Nickel alloys generally exhibit higher material costs compared to Monel due to their complex compositions and enhanced mechanical properties. Monel, primarily composed of nickel and copper, offers a cost-effective alternative with good corrosion resistance in marine and chemical environments. When evaluating total expenses, consider fabrication and maintenance costs alongside initial material price differences between nickel alloys and Monel.

Fabrication and Machinability

Nickel alloys generally exhibit superior corrosion resistance and high-temperature strength, facilitating more versatile fabrication methods such as welding and forming compared to Monel. Monel alloys, primarily composed of nickel and copper, offer excellent machinability with less tool wear and faster cutting speeds, making them ideal for complex, precision machining tasks. Fabrication of nickel alloys often requires specialized techniques to manage work hardening and thermal conductivity, whereas Monel benefits from smoother machining processes but may present challenges in welding due to its copper content.

Heat Resistance and Thermal Stability

Nickel alloys offer superior heat resistance and thermal stability compared to Monel, maintaining strength and corrosion resistance at temperatures up to 1200degF (650degC). Monel, primarily composed of nickel and copper, performs well in moderate heat environments around 600degF (315degC) but may lose mechanical integrity under prolonged high-temperature exposure. Selecting a nickel alloy ensures enhanced performance in high-temperature applications such as aerospace and power generation due to its optimized thermal properties.

Longevity and Maintenance Requirements

Nickel alloys exhibit superior longevity due to their enhanced corrosion resistance and high-temperature stability, making them ideal for harsh industrial environments. Monel, primarily composed of nickel and copper, offers excellent resistance to seawater corrosion but requires more frequent maintenance in acidic conditions. The choice between nickel alloy and Monel depends largely on specific environmental exposures and maintenance capabilities, with nickel alloys generally demanding less upkeep over time.

Choosing Between Nickel Alloy and Monel: Key Considerations

Nickel alloy offers superior corrosion resistance and high-temperature strength, making it ideal for chemical processing and aerospace applications. Monel, primarily composed of nickel and copper, excels in marine environments due to its exceptional resistance to seawater corrosion and biofouling. Selecting between nickel alloy and Monel depends on factors such as mechanical requirements, environmental exposure, and cost-effectiveness for the intended application.

Nickel Alloy vs Monel Infographic

materialdif.com

materialdif.com