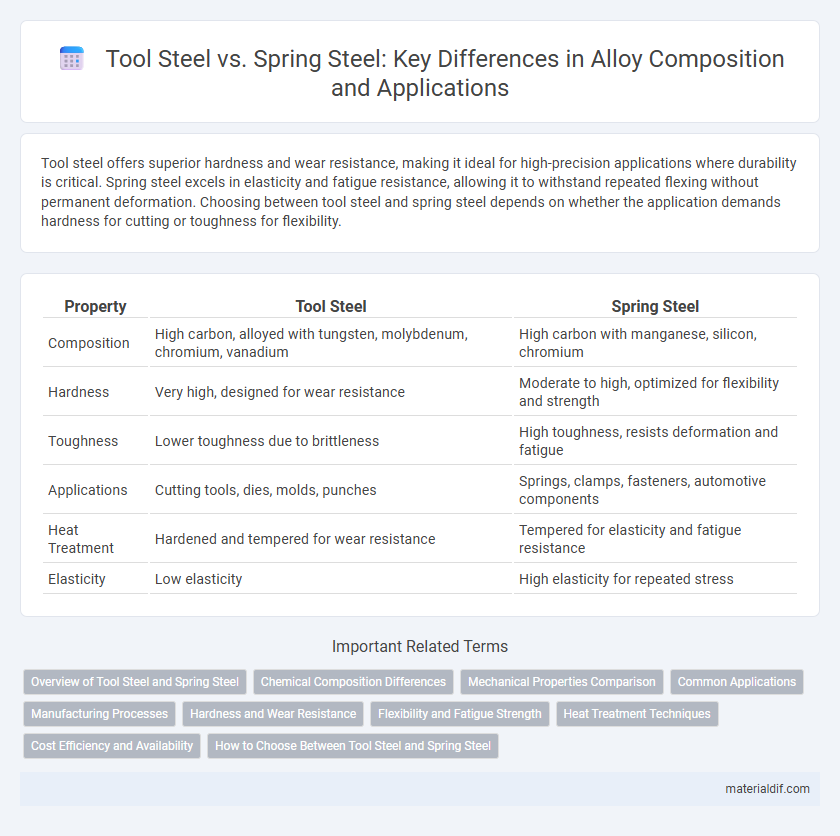

Tool steel offers superior hardness and wear resistance, making it ideal for high-precision applications where durability is critical. Spring steel excels in elasticity and fatigue resistance, allowing it to withstand repeated flexing without permanent deformation. Choosing between tool steel and spring steel depends on whether the application demands hardness for cutting or toughness for flexibility.

Table of Comparison

| Property | Tool Steel | Spring Steel |

|---|---|---|

| Composition | High carbon, alloyed with tungsten, molybdenum, chromium, vanadium | High carbon with manganese, silicon, chromium |

| Hardness | Very high, designed for wear resistance | Moderate to high, optimized for flexibility and strength |

| Toughness | Lower toughness due to brittleness | High toughness, resists deformation and fatigue |

| Applications | Cutting tools, dies, molds, punches | Springs, clamps, fasteners, automotive components |

| Heat Treatment | Hardened and tempered for wear resistance | Tempered for elasticity and fatigue resistance |

| Elasticity | Low elasticity | High elasticity for repeated stress |

Overview of Tool Steel and Spring Steel

Tool steel is a high-carbon alloy known for its hardness, resistance to abrasion, and ability to retain a sharp edge, making it ideal for cutting tools, molds, and dies. Spring steel, characterized by its high yield strength and elasticity, is specifically designed to return to its original shape after deformation, commonly used in automotive springs and high-stress applications. Both steels undergo heat treatment to enhance mechanical properties but serve distinct industrial purposes based on their unique compositions and performance requirements.

Chemical Composition Differences

Tool steel typically contains higher carbon content ranging from 0.5% to 1.5%, along with alloying elements such as tungsten, molybdenum, vanadium, and chromium to enhance hardness, wear resistance, and heat resistance. Spring steel generally has a lower carbon content, approximately 0.4% to 0.7%, combined with manganese and silicon to improve elasticity and tensile strength for optimal performance under repeated stress. The distinct alloying additions in tool steel create superior hardness and thermal stability, whereas spring steel's composition prioritizes flexibility and durability.

Mechanical Properties Comparison

Tool steel exhibits superior hardness and wear resistance, making it ideal for cutting and shaping applications, while spring steel offers exceptional elasticity and fatigue strength crucial for flexible components. The tensile strength of tool steel typically ranges between 600 to 1200 MPa, whereas spring steel can endure similar strengths but with higher elongation before failure. Impact toughness is generally higher in spring steel, allowing it to absorb repeated loads without permanent deformation, unlike the more brittle tool steel.

Common Applications

Tool steel is commonly used in cutting tools, dies, and molds due to its hardness, wear resistance, and ability to retain a sharp edge under high temperatures. Spring steel finds widespread application in the manufacturing of springs, clips, and fasteners, leveraging its exceptional elasticity and fatigue resistance. Both steels serve critical functions across automotive, aerospace, and industrial machinery sectors, with tool steel excelling in precision components and spring steel in resilient mechanical parts.

Manufacturing Processes

Tool steel undergoes processes such as hardening through quenching and tempering to enhance wear resistance and durability, making it ideal for cutting and shaping tools. Spring steel is typically processed with precise heat treatments and cold working techniques, including quenching and tempering, to optimize its high yield strength and elasticity for load-bearing applications. Both steels require controlled manufacturing conditions to achieve their characteristic mechanical properties critical to their specific industrial functions.

Hardness and Wear Resistance

Tool steel exhibits higher hardness and superior wear resistance compared to spring steel, making it ideal for cutting, shaping, and machining applications. Spring steel offers moderate hardness with excellent elasticity and fatigue resistance, suitable for components requiring flexibility and durability under cyclic stress. The alloy composition of tool steel, often containing tungsten, molybdenum, and chromium, contributes significantly to its enhanced hardness and wear resistance properties.

Flexibility and Fatigue Strength

Tool steel exhibits superior fatigue strength due to its high hardness and wear resistance, making it ideal for cutting and shaping applications under repetitive stress. Spring steel offers greater flexibility and excellent elasticity, allowing it to withstand repeated bending without permanent deformation, which is essential in spring manufacturing. The choice between tool steel and spring steel depends on the required balance between fatigue strength and flexibility for specific alloy applications.

Heat Treatment Techniques

Tool steel undergoes precise heat treatment processes such as quenching and tempering to achieve high hardness and wear resistance essential for cutting and shaping tools. Spring steel requires controlled heat treatment techniques like annealing and hardening followed by tempering to provide excellent elasticity and fatigue resistance for load-bearing applications. The selection of heat treatment parameters critically influences the microstructure and mechanical properties tailored to each steel's functional requirements.

Cost Efficiency and Availability

Tool steel offers higher cost efficiency due to its superior wear resistance and longer lifespan in industrial applications. Spring steel, while generally more affordable and widely available, often incurs higher replacement costs because of its lower durability under continuous stress. The choice depends on balancing upfront material costs against long-term maintenance expenses.

How to Choose Between Tool Steel and Spring Steel

Choosing between tool steel and spring steel depends on the specific application requirements, such as hardness, wear resistance, and elasticity. Tool steel is ideal for applications demanding high hardness and abrasion resistance, commonly used in cutting tools and dies. Spring steel offers superior flexibility and fatigue resistance, making it suitable for components like springs and high-stress mechanical parts.

Tool Steel vs Spring Steel Infographic

materialdif.com

materialdif.com