Maraging steel offers superior strength and toughness due to its unique aging process, making it ideal for high-stress applications. High-speed steel excels in maintaining hardness at elevated temperatures, which enhances cutting performance and wear resistance. Choosing between the two depends on whether strength or heat resistance is the primary requirement for the alloy's use.

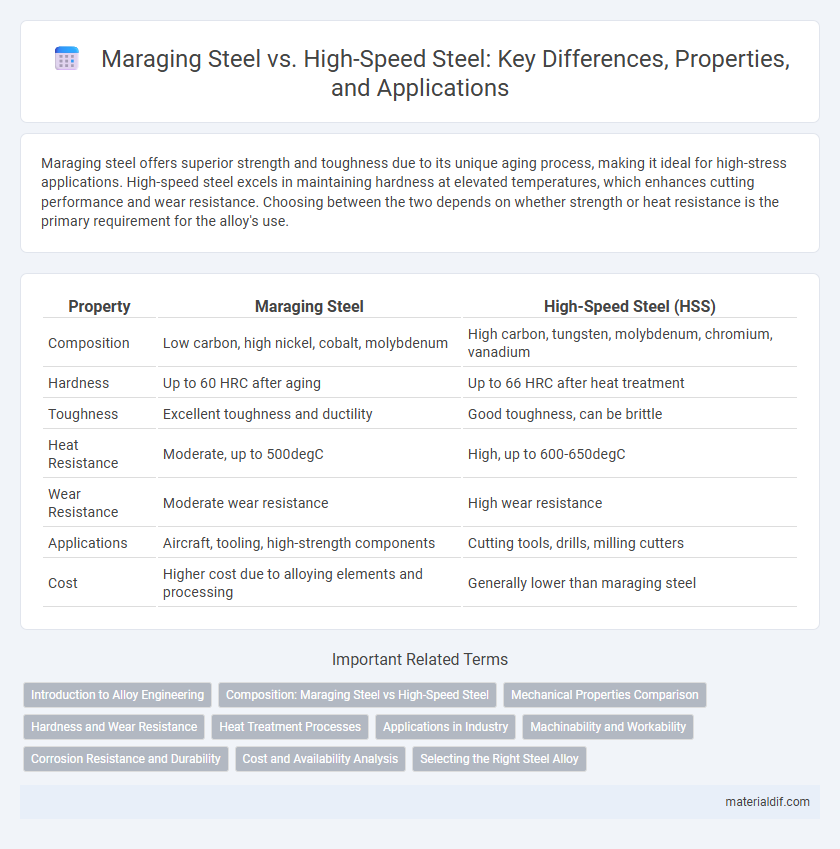

Table of Comparison

| Property | Maraging Steel | High-Speed Steel (HSS) |

|---|---|---|

| Composition | Low carbon, high nickel, cobalt, molybdenum | High carbon, tungsten, molybdenum, chromium, vanadium |

| Hardness | Up to 60 HRC after aging | Up to 66 HRC after heat treatment |

| Toughness | Excellent toughness and ductility | Good toughness, can be brittle |

| Heat Resistance | Moderate, up to 500degC | High, up to 600-650degC |

| Wear Resistance | Moderate wear resistance | High wear resistance |

| Applications | Aircraft, tooling, high-strength components | Cutting tools, drills, milling cutters |

| Cost | Higher cost due to alloying elements and processing | Generally lower than maraging steel |

Introduction to Alloy Engineering

Maraging steel is a high-strength alloy primarily composed of iron and nickel, which undergoes a unique aging process to achieve exceptional toughness and fatigue resistance, making it ideal for aerospace and tooling applications. High-speed steel, enriched with tungsten, molybdenum, and vanadium, offers superior hardness and hot hardness, enabling efficient cutting performance at elevated temperatures. Alloy engineering optimizes these materials' compositions and heat treatments to tailor mechanical properties for specific industrial uses.

Composition: Maraging Steel vs High-Speed Steel

Maraging steel features a high nickel content, typically around 15-25%, combined with cobalt, molybdenum, and titanium, resulting in superior strength and toughness through age hardening. High-speed steel (HSS) primarily consists of high carbon with significant amounts of tungsten, molybdenum, chromium, and vanadium, optimizing wear resistance and hot hardness. The distinct alloying elements in maraging steel promote precipitation hardening, whereas HSS relies on carbide formation for hardness retention at elevated temperatures.

Mechanical Properties Comparison

Maraging steel exhibits exceptional tensile strength ranging from 1,700 to 2,400 MPa, coupled with superior toughness and ductility compared to high-speed steel (HSS), which typically offers tensile strength around 1,200 MPa but higher hardness up to 65 HRC. The low carbon content and aging process in maraging steel result in minimal distortion and enhanced fatigue resistance, while HSS excels in wear resistance and hot hardness for cutting tool applications. When comparing mechanical properties, maraging steel's fracture toughness and impact strength outperform HSS, making it ideal for aerospace and tooling components requiring high strength and toughness with moderate hardness.

Hardness and Wear Resistance

Maraging steel exhibits superior hardness, typically reaching 55-62 HRC, compared to high-speed steel's range of 60-65 HRC, but its wear resistance is enhanced by its unique aging process that forms intermetallic compounds. High-speed steel, containing high carbon and alloy elements like tungsten and molybdenum, offers excellent wear resistance under high-temperature cutting conditions. Maraging steel's combination of high strength and toughness with good wear resistance makes it ideal for applications requiring dimensional stability and durability under mechanical stress.

Heat Treatment Processes

Maraging steel undergoes solution annealing followed by aging at 480-500degC, which significantly enhances its strength and toughness through precipitation hardening of intermetallic compounds. High-speed steel requires a multi-stage heat treatment involving austenitizing at 1,200degC, quenching, and triple tempering between 540-560degC to achieve optimal hardness and wear resistance. The controlled heat treatment of maraging steel results in superior fracture toughness compared to the wear-resistant, high hardness microstructure developed in high-speed steel.

Applications in Industry

Maraging steel offers exceptional strength and toughness, making it ideal for aerospace and tooling applications requiring high-impact resistance and dimensional stability. High-speed steel excels in cutting and machining tools due to its ability to retain hardness at elevated temperatures, commonly used in manufacturing drills, saw blades, and milling cutters. Both alloys serve critical roles in industrial settings, with maraging steel favored for structural components and high-speed steel preferred for precision cutting tools.

Machinability and Workability

Maraging steel offers superior machinability compared to high-speed steel due to its lower carbon content and softer phase before aging, allowing easier cutting and shaping with less tool wear. High-speed steel, known for its exceptional hardness and heat resistance, exhibits lower machinability but enhanced workability in high-temperature applications. Optimizing alloy selection based on these machinability and workability differences improves manufacturing efficiency and component performance in precision engineering.

Corrosion Resistance and Durability

Maraging steel exhibits superior corrosion resistance compared to high-speed steel due to its low carbon content and high nickel alloy composition, which forms a passive oxide layer that protects against rust and oxidation. In terms of durability, maraging steel offers exceptional toughness and resistance to cracking under stress, making it ideal for high-strength applications. High-speed steel, while harder and capable of maintaining sharp cutting edges at elevated temperatures, generally shows lower corrosion resistance and is more prone to wear in corrosive environments.

Cost and Availability Analysis

Maraging steel typically commands a higher upfront cost due to its complex alloying elements like nickel and cobalt, which are less abundant and more expensive than the tungsten and molybdenum mainly found in high-speed steel (HSS). Availability of maraging steel is more limited as it requires specialized production processes predominantly in aerospace and tooling industries, while HSS enjoys widespread global availability due to its extensive use in cutting tools and machining applications. Cost-efficiency of HSS is generally favored for mass production because of lower material costs and easier procurement, whereas maraging steel's superior mechanical properties justify its premium price in high-performance, niche applications.

Selecting the Right Steel Alloy

Selecting the right steel alloy depends on the specific application requirements such as strength, toughness, and heat resistance. Maraging steel offers exceptional strength and toughness with low carbon content, making it ideal for aerospace and tooling applications requiring high mechanical performance. High-speed steel excels in maintaining hardness at elevated temperatures, preferred for cutting tools and machining operations where wear resistance and thermal stability are critical.

Maraging Steel vs High-Speed Steel Infographic

materialdif.com

materialdif.com