Hot-rolled alloy undergoes processing at high temperatures, resulting in a rougher surface finish and greater dimensional variability, which is ideal for structural applications where strength is prioritized over aesthetics. Cold-rolled alloy is processed at or near room temperature, producing a smoother surface, tighter tolerances, and enhanced mechanical properties, making it suitable for precision components and decorative uses. Choosing between hot-rolled and cold-rolled alloy depends on the specific requirements of strength, surface quality, and dimensional accuracy for the intended application.

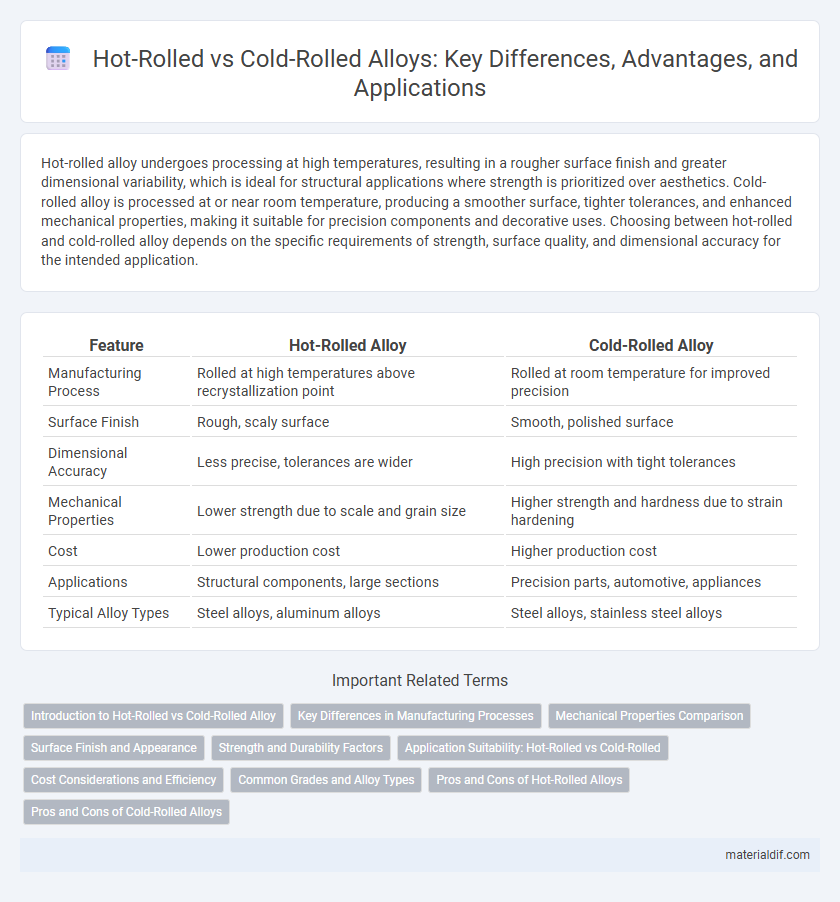

Table of Comparison

| Feature | Hot-Rolled Alloy | Cold-Rolled Alloy |

|---|---|---|

| Manufacturing Process | Rolled at high temperatures above recrystallization point | Rolled at room temperature for improved precision |

| Surface Finish | Rough, scaly surface | Smooth, polished surface |

| Dimensional Accuracy | Less precise, tolerances are wider | High precision with tight tolerances |

| Mechanical Properties | Lower strength due to scale and grain size | Higher strength and hardness due to strain hardening |

| Cost | Lower production cost | Higher production cost |

| Applications | Structural components, large sections | Precision parts, automotive, appliances |

| Typical Alloy Types | Steel alloys, aluminum alloys | Steel alloys, stainless steel alloys |

Introduction to Hot-Rolled vs Cold-Rolled Alloy

Hot-rolled alloy is processed at high temperatures above its recrystallization point, resulting in a rough surface finish and improved ductility, making it suitable for structural applications. Cold-rolled alloy undergoes further processing at room temperature, enhancing its strength, surface smoothness, and dimensional accuracy for precision components. Understanding these processes helps select the appropriate alloy type based on mechanical properties and application requirements.

Key Differences in Manufacturing Processes

Hot-rolled alloy undergoes deformation at high temperatures above its recrystallization point, allowing easier shaping and resulting in a rougher surface finish with less precise dimensions. Cold-rolled alloy is processed at or near room temperature, which enhances strength through strain hardening and produces a smoother surface with tighter dimensional tolerances. The manufacturing process directly influences mechanical properties, surface texture, and applications of both hot-rolled and cold-rolled alloys.

Mechanical Properties Comparison

Hot-rolled alloys exhibit greater ductility and improved toughness due to the slower cooling process, which results in a coarser grain structure. Cold-rolled alloys offer higher tensile strength and better surface finish because the material undergoes work hardening and strain hardening during deformation at room temperature. The mechanical properties of cold-rolled alloys make them ideal for applications requiring precise dimensional tolerances and enhanced strength.

Surface Finish and Appearance

Hot-rolled alloy typically exhibits a rougher surface finish with a scaled appearance due to exposure to high temperatures during processing, making it less suitable for applications requiring a smooth or decorative surface. Cold-rolled alloy undergoes further processing at room temperature, resulting in a smoother, shinier surface with better dimensional accuracy, ideal for aesthetic and precision purposes. The improved surface finish of cold-rolled alloys enhances paint adhesion and corrosion resistance compared to hot-rolled counterparts.

Strength and Durability Factors

Hot-rolled alloys exhibit superior strength due to their coarse grain structure formed at high temperatures, enhancing durability under heavy loads and impact resistance. Cold-rolled alloys possess higher tensile strength and better surface finish resulting from strain hardening during the rolling process, making them ideal for precision applications requiring enhanced fatigue resistance. The choice between hot-rolled and cold-rolled alloys depends on specific strength and durability requirements, with hot-rolled alloys favored for structural uses and cold-rolled alloys preferred for detailed, high-strength components.

Application Suitability: Hot-Rolled vs Cold-Rolled

Hot-rolled alloys are suitable for applications requiring enhanced ductility and toughness, commonly used in structural components and heavy machinery where dimensional precision is less critical. Cold-rolled alloys offer superior surface finish and tighter tolerances, making them ideal for automotive parts, appliances, and precision industrial equipment requiring exact dimensions and smooth surfaces. Choosing between hot-rolled and cold-rolled alloys depends on balancing mechanical properties with application-specific demands, such as strength, appearance, and fabrication processes.

Cost Considerations and Efficiency

Hot-rolled alloys generally incur lower production costs due to faster processing times and reduced energy consumption compared to cold-rolled alloys, which require additional finishing steps. Cold-rolled alloys offer higher dimensional accuracy and surface finish, reducing machining costs in precision applications despite their higher initial price. Choosing between hot-rolled and cold-rolled alloys depends on balancing raw material expenses with post-processing efficiency and final product requirements.

Common Grades and Alloy Types

Hot-rolled alloys commonly include low to medium carbon steels like ASTM A36 and A572 grades, primarily used for structural applications due to their improved ductility and toughness. Cold-rolled alloys often feature higher carbon content such as AISI 1018 and 1020, providing enhanced surface finish, dimensional accuracy, and strength ideal for precision components. Popular alloy types in both processes encompass carbon steel, stainless steel, and aluminum alloys, each selected based on required mechanical properties and application-specific performance criteria.

Pros and Cons of Hot-Rolled Alloys

Hot-rolled alloys offer improved ductility and lower production costs due to the high-temperature rolling process that allows easier shaping and forming. These alloys typically exhibit a rougher surface finish and less precise dimensions compared to cold-rolled alloys, resulting in increased post-processing requirements. However, their enhanced toughness and lower residual stress make hot-rolled alloys ideal for applications demanding high strength and durability under dynamic loads.

Pros and Cons of Cold-Rolled Alloys

Cold-rolled alloys offer superior surface finish and tighter dimensional tolerances compared to hot-rolled alloys, making them ideal for precision applications. Their increased strength and hardness result from strain hardening during the cold rolling process, enhancing mechanical properties but reducing ductility. However, cold-rolled alloys typically have higher production costs and may require additional annealing steps to relieve internal stresses.

Hot-rolled alloy vs Cold-rolled alloy Infographic

materialdif.com

materialdif.com