Monel offers superior strength and corrosion resistance in highly acidic environments compared to Cupro-nickel, making it ideal for marine and chemical processing applications. Cupro-nickel, however, excels in seawater resistance and is more cost-effective, commonly used in piping, heat exchangers, and desalination plants. Both alloys provide excellent durability, but the choice depends on specific environmental conditions and budget constraints.

Table of Comparison

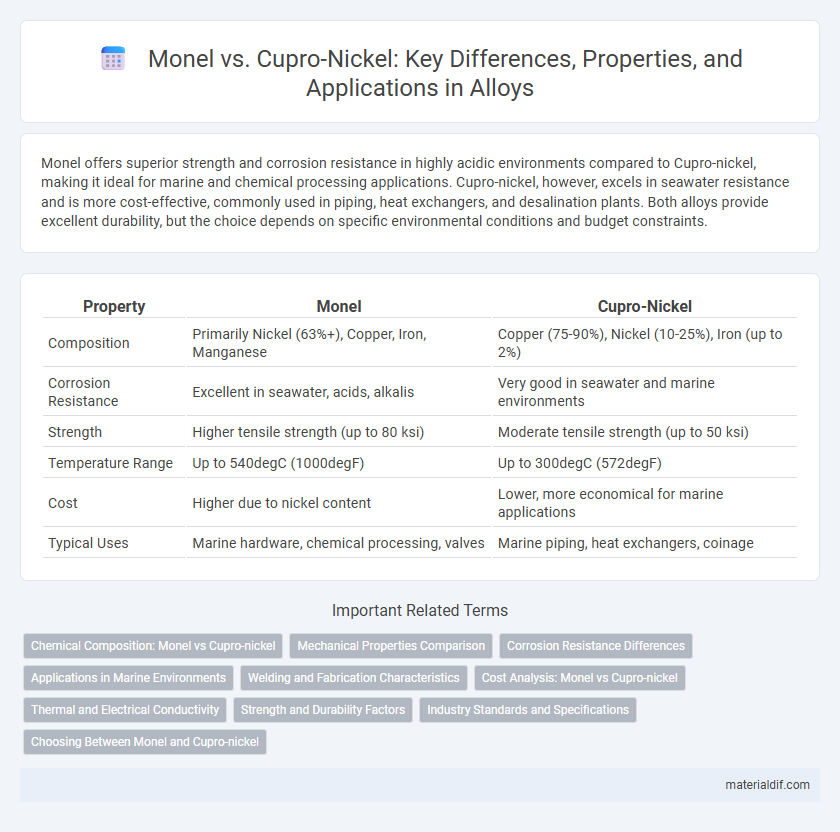

| Property | Monel | Cupro-Nickel |

|---|---|---|

| Composition | Primarily Nickel (63%+), Copper, Iron, Manganese | Copper (75-90%), Nickel (10-25%), Iron (up to 2%) |

| Corrosion Resistance | Excellent in seawater, acids, alkalis | Very good in seawater and marine environments |

| Strength | Higher tensile strength (up to 80 ksi) | Moderate tensile strength (up to 50 ksi) |

| Temperature Range | Up to 540degC (1000degF) | Up to 300degC (572degF) |

| Cost | Higher due to nickel content | Lower, more economical for marine applications |

| Typical Uses | Marine hardware, chemical processing, valves | Marine piping, heat exchangers, coinage |

Chemical Composition: Monel vs Cupro-nickel

Monel alloys typically contain around 65-70% nickel and 20-29% copper, with small amounts of iron, manganese, and trace elements, which provide high strength and corrosion resistance. Cupro-nickel, on the other hand, consists mainly of 75-90% copper and 10-25% nickel, sometimes with iron and manganese, offering excellent resistance to seawater corrosion and biofouling. The higher nickel content in Monel results in superior mechanical properties, while the copper-rich composition of Cupro-nickel enhances thermal conductivity and anti-microbial properties.

Mechanical Properties Comparison

Monel alloys exhibit superior tensile strength ranging from 550 to 900 MPa compared to cupro-nickel's typical 300 to 500 MPa, making Monel ideal for high-stress applications. Monel also offers higher yield strength and greater hardness, with values up to 385 HV, whereas cupro-nickel hardness typically falls below 200 HV. Both alloys provide excellent corrosion resistance, but Monel's mechanical robustness gives it a distinct advantage in demanding structural environments.

Corrosion Resistance Differences

Monel alloys exhibit superior corrosion resistance compared to Cupro-nickel, particularly in marine and acidic environments due to their high nickel content and balanced addition of copper and other elements like iron and manganese. Cupro-nickel offers good resistance to seawater corrosion and biofouling but is more susceptible to stress corrosion cracking and dezincification in specific aggressive chloride conditions. The enhanced corrosion resistance of Monel makes it the preferred choice for chemical processing, marine engineering, and offshore applications where durability against sulfides and chlorides is critical.

Applications in Marine Environments

Monel alloys excel in marine environments due to their exceptional corrosion resistance against saltwater and biofouling, making them ideal for seawater piping, pump shafts, and marine hardware. Cupro-nickel is preferred for heat exchangers, condenser tubes, and seawater valves because of its superior resistance to erosion-corrosion and microbial attack. Both alloys feature strong durability in harsh marine conditions but differ in specific performance characteristics suited to distinct marine applications.

Welding and Fabrication Characteristics

Monel offers superior weldability with excellent corrosion resistance in marine environments, making it highly suitable for fabrication involving complex weld joints. Cupro-nickel provides good welding characteristics but tends to require more precise control to prevent grain boundary sensitization during fabrication. Both alloys necessitate appropriate post-weld heat treatments to maintain mechanical strength and corrosion resistance in demanding applications.

Cost Analysis: Monel vs Cupro-nickel

Monel alloys generally exhibit higher raw material costs compared to Cupro-nickel due to their elevated nickel and copper content, impacting overall project budgets. Cupro-nickel offers a cost-efficient alternative with lower material and manufacturing expenses while maintaining corrosion resistance suitable for marine applications. Lifecycle cost analysis reveals Cupro-nickel often results in reduced maintenance and replacement costs, enhancing long-term economic viability.

Thermal and Electrical Conductivity

Monel alloy exhibits significantly higher thermal conductivity, approximately 22 W/m*K, compared to Cupro-nickel's thermal conductivity ranging from 20 to 40 W/m*K depending on composition, with Monel generally more consistent. Electrical conductivity in Monel is lower, around 20% IACS (International Annealed Copper Standard), whereas Cupro-nickel alloys range from 5 to 25% IACS, often surpassing Monel in electrical conductivity for certain grades. The differences in conductivity impact applications; Monel suits environments demanding corrosion resistance with moderate conductivity, while Cupro-nickel is preferred where enhanced electrical or thermal conductivity is critical.

Strength and Durability Factors

Monel alloys, primarily composed of nickel and copper, exhibit superior strength and corrosion resistance compared to cupro-nickel due to higher nickel content and added elements like iron and manganese. Cupro-nickel alloys offer excellent resistance to seawater corrosion and biofouling but generally have lower tensile strength and hardness than Monel, making Monel more suitable for high-stress marine and industrial applications. The durability of Monel alloys under extreme temperature and pressure conditions surpasses cupro-nickel, contributing to longer service life in demanding environments.

Industry Standards and Specifications

Monel alloys conform to ASTM B127 and B164 standards for corrosion resistance and strength in marine and chemical environments, while cupro-nickel typically meets ASTM B122 and B466 specifications, emphasizing its excellent performance in seawater applications. Monel's high nickel content provides superior mechanical properties under ASTM guidelines, making it ideal for aerospace and marine industry demands. Cupro-nickel alloys are favored under ASTM standards for piping and heat exchanger systems due to their resistance to biofouling and seawater corrosion.

Choosing Between Monel and Cupro-nickel

Choosing between Monel and Cupro-nickel depends on corrosion resistance and strength requirements; Monel alloys offer superior resistance to acidic and saltwater environments, making them ideal for marine and chemical applications. Cupro-nickel alloys provide excellent resistance to biofouling and seawater corrosion with good thermal conductivity, suitable for heat exchangers and desalination plants. Consider mechanical properties, cost, and specific environmental factors when selecting between the two alloys for optimal performance.

Monel vs Cupro-nickel Infographic

materialdif.com

materialdif.com