Copper-nickel alloys offer excellent corrosion resistance and improved durability in marine and industrial environments, making them ideal for applications exposed to harsh conditions. Beryllium-copper alloys provide superior strength, electrical conductivity, and non-magnetic properties, which are essential for precision instruments and electronic components. Choosing between these alloys depends on balancing corrosion resistance with mechanical strength and conductivity requirements.

Table of Comparison

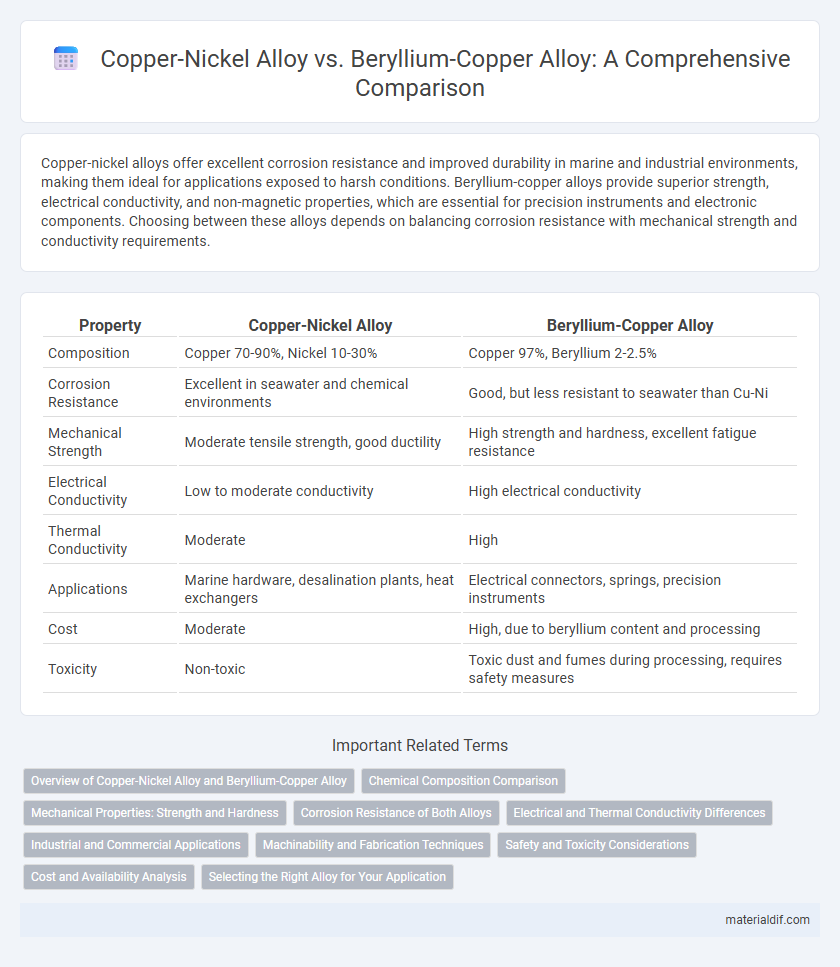

| Property | Copper-Nickel Alloy | Beryllium-Copper Alloy |

|---|---|---|

| Composition | Copper 70-90%, Nickel 10-30% | Copper 97%, Beryllium 2-2.5% |

| Corrosion Resistance | Excellent in seawater and chemical environments | Good, but less resistant to seawater than Cu-Ni |

| Mechanical Strength | Moderate tensile strength, good ductility | High strength and hardness, excellent fatigue resistance |

| Electrical Conductivity | Low to moderate conductivity | High electrical conductivity |

| Thermal Conductivity | Moderate | High |

| Applications | Marine hardware, desalination plants, heat exchangers | Electrical connectors, springs, precision instruments |

| Cost | Moderate | High, due to beryllium content and processing |

| Toxicity | Non-toxic | Toxic dust and fumes during processing, requires safety measures |

Overview of Copper-Nickel Alloy and Beryllium-Copper Alloy

Copper-nickel alloys, primarily composed of copper and nickel with trace amounts of iron and manganese, are known for excellent corrosion resistance, especially in marine environments, and strong antimicrobial properties. Beryllium-copper alloys combine copper with beryllium typically between 0.5% to 3%, offering superior strength, durability, and electrical conductivity along with non-sparking characteristics ideal for hazardous environments. Both alloys are valued for their unique mechanical and chemical properties, making them essential in aerospace, marine engineering, and electronic applications.

Chemical Composition Comparison

Copper-Nickel alloys primarily consist of 60-90% copper and 10-40% nickel, offering excellent corrosion resistance and high strength in marine environments. Beryllium-Copper alloys contain 0.5-3% beryllium with the balance mostly copper, resulting in superior hardness and non-sparking properties. The chemical composition difference directly influences mechanical characteristics, with nickel enhancing toughness and beryllium providing exceptional elasticity and electrical conductivity.

Mechanical Properties: Strength and Hardness

Copper-nickel alloys exhibit moderate strength and hardness with excellent corrosion resistance, making them ideal for marine and industrial applications. Beryllium-copper alloys offer superior strength and hardness due to their age-hardening capability, providing enhanced wear resistance and electrical conductivity. The mechanical superiority of beryllium-copper alloys makes them suitable for demanding aerospace and precision instrument components.

Corrosion Resistance of Both Alloys

Copper-nickel alloys exhibit superior corrosion resistance in marine environments due to their excellent resistance to biofouling and stress corrosion cracking. Beryllium-copper alloys offer good corrosion resistance in mild environments but are more susceptible to dezincification and stress corrosion in aggressive conditions. The choice between copper-nickel and beryllium-copper alloys depends on specific application requirements, especially exposure to saltwater or acidic conditions.

Electrical and Thermal Conductivity Differences

Copper-nickel alloys exhibit significantly lower electrical and thermal conductivity compared to beryllium-copper alloys, with conductivity values typically around 20-50% IACS (International Annealed Copper Standard) for copper-nickel and up to 25% IACS but with enhanced mechanical strength for beryllium-copper. The presence of beryllium in copper increases hardness and maintains relatively high thermal conductivity, making beryllium-copper alloys ideal for applications requiring efficient heat dissipation and electrical performance. Copper-nickel alloys' reduced conductivity stems from nickel's impact on the electron flow, making them more suitable for corrosion resistance rather than high conductivity needs.

Industrial and Commercial Applications

Copper-nickel alloys are widely used in marine engineering and desalination plants due to their excellent corrosion resistance and biofouling prevention, making them ideal for heat exchangers and piping systems. Beryllium-copper alloys, known for their superior strength, conductivity, and non-sparking properties, are favored in aerospace, electrical connectors, and precision instruments requiring durability and electrical performance. Both alloys serve distinct industrial and commercial sectors, with copper-nickel excelling in harsh environmental conditions and beryllium-copper providing reliability in electrical and mechanical applications.

Machinability and Fabrication Techniques

Copper-nickel alloys offer moderate machinability, typically requiring slower cutting speeds and specialized tooling to manage work hardening, whereas beryllium-copper alloys demonstrate superior machinability due to their fine grain structure and enhanced chip control. Fabrication techniques for copper-nickel alloys often involve conventional machining followed by annealing to relieve stresses, while beryllium-copper alloys benefit from precipitation hardening and can be efficiently formed through stamping, bending, and precision machining. Selection between the two alloys depends on balancing machinability with desired mechanical properties and application-specific fabrication requirements.

Safety and Toxicity Considerations

Copper-nickel alloys exhibit lower toxicity levels compared to beryllium-copper alloys, which contain beryllium known for its carcinogenic and respiratory health risks during machining and welding. Safety protocols for beryllium-copper alloys require strict exposure controls, including proper ventilation and personal protective equipment to mitigate inhalation hazards. Copper-nickel alloys offer safer handling and environmental impact, reducing occupational health concerns in industrial applications.

Cost and Availability Analysis

Copper-nickel alloys generally offer a more cost-effective solution than beryllium-copper alloys, with lower raw material expenses and widespread availability due to abundant copper and nickel sources. Beryllium-copper alloys incur higher costs influenced by beryllium's scarcity and the stringent safety protocols required for its handling and processing. Availability challenges for beryllium-copper limit large-scale production, whereas copper-nickel alloys benefit from established global supply chains ensuring consistent accessibility.

Selecting the Right Alloy for Your Application

Copper-Nickel alloys offer excellent corrosion resistance and strength, making them ideal for marine and chemical environments where durability and resistance to biofouling are critical. Beryllium-Copper alloys provide superior hardness, electrical conductivity, and non-sparking properties, which suit applications requiring precision, electrical components, and safety in explosive atmospheres. Selecting the right alloy depends on balancing mechanical performance, corrosion resistance, conductivity, and cost factors based on specific application requirements.

Copper-Nickel Alloy vs Beryllium-Copper Alloy Infographic

materialdif.com

materialdif.com