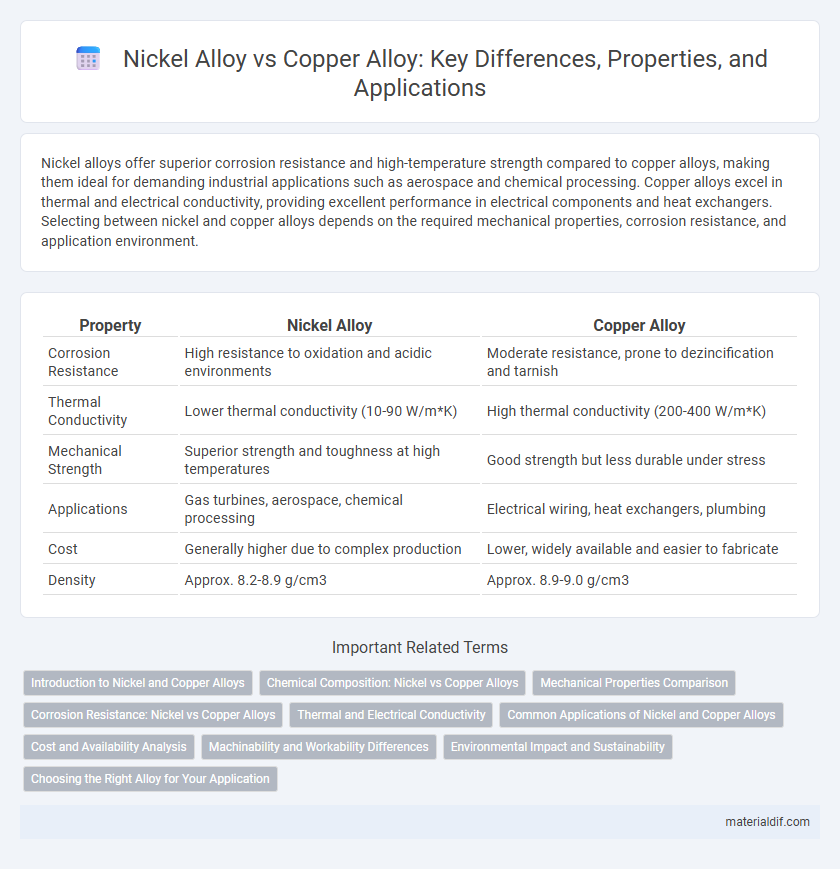

Nickel alloys offer superior corrosion resistance and high-temperature strength compared to copper alloys, making them ideal for demanding industrial applications such as aerospace and chemical processing. Copper alloys excel in thermal and electrical conductivity, providing excellent performance in electrical components and heat exchangers. Selecting between nickel and copper alloys depends on the required mechanical properties, corrosion resistance, and application environment.

Table of Comparison

| Property | Nickel Alloy | Copper Alloy |

|---|---|---|

| Corrosion Resistance | High resistance to oxidation and acidic environments | Moderate resistance, prone to dezincification and tarnish |

| Thermal Conductivity | Lower thermal conductivity (10-90 W/m*K) | High thermal conductivity (200-400 W/m*K) |

| Mechanical Strength | Superior strength and toughness at high temperatures | Good strength but less durable under stress |

| Applications | Gas turbines, aerospace, chemical processing | Electrical wiring, heat exchangers, plumbing |

| Cost | Generally higher due to complex production | Lower, widely available and easier to fabricate |

| Density | Approx. 8.2-8.9 g/cm3 | Approx. 8.9-9.0 g/cm3 |

Introduction to Nickel and Copper Alloys

Nickel alloys exhibit exceptional corrosion resistance, high strength, and excellent performance in extreme temperatures, making them ideal for aerospace, chemical processing, and marine applications. Copper alloys provide superior electrical and thermal conductivity alongside good corrosion resistance, commonly used in electrical wiring, plumbing, and heat exchangers. Both alloys offer distinct advantages, with nickel alloys favored for durability and copper alloys selected for conductivity and formability.

Chemical Composition: Nickel vs Copper Alloys

Nickel alloys primarily consist of nickel as the base metal, often combined with elements like chromium, iron, and molybdenum to enhance corrosion resistance and mechanical strength. Copper alloys, typically comprising copper mixed with zinc (brass), tin (bronze), or aluminum, emphasize excellent electrical and thermal conductivity alongside good corrosion resistance. The distinct chemical compositions define their suitability, with nickel alloys favored for high-temperature and corrosive environments, while copper alloys excel in electrical applications and moderate corrosion conditions.

Mechanical Properties Comparison

Nickel alloys exhibit superior mechanical properties compared to copper alloys, including higher tensile strength and enhanced corrosion resistance, making them ideal for high-stress environments. Copper alloys typically provide better electrical and thermal conductivity but lower yield strength and hardness. The choice between nickel and copper alloys depends on application requirements such as strength, durability, and environmental exposure.

Corrosion Resistance: Nickel vs Copper Alloys

Nickel alloys exhibit superior corrosion resistance compared to copper alloys, especially in harsh chemical environments and high-temperature applications. Their ability to withstand oxidation, acid attacks, and stress corrosion cracking makes them ideal for marine, chemical processing, and aerospace industries. Copper alloys, while offering good antimicrobial properties and thermal conductivity, generally show higher susceptibility to corrosion in acidic or chloride-rich conditions.

Thermal and Electrical Conductivity

Nickel alloys exhibit lower thermal and electrical conductivity compared to copper alloys, making them ideal for high-temperature and corrosion-resistant applications where electrical insulation is crucial. Copper alloys provide superior electrical and thermal conductivity, which is essential for efficient heat transfer and electrical performance in wiring and heat exchanger systems. The choice between nickel and copper alloys depends on balancing conductivity needs with mechanical strength and environmental resistance.

Common Applications of Nickel and Copper Alloys

Nickel alloys are extensively used in aerospace, chemical processing, and power generation industries due to their exceptional corrosion resistance and high-temperature strength. Copper alloys find common applications in electrical wiring, plumbing, and heat exchangers because of their excellent electrical conductivity and thermal performance. Both alloys play critical roles in manufacturing components that require durability, conductivity, and resistance to environmental degradation.

Cost and Availability Analysis

Nickel alloys generally have a higher cost compared to copper alloys due to the greater expense of raw nickel and more complex manufacturing processes. Copper alloys benefit from widespread availability and lower price volatility given the extensive global supply and established mining infrastructure. Choosing between nickel and copper alloys should consider both budget constraints and material sourcing to optimize project feasibility.

Machinability and Workability Differences

Nickel alloys exhibit superior machinability compared to copper alloys due to their higher hardness and thermal resistance, allowing for precision machining in high-stress environments. Copper alloys demonstrate excellent workability with better ductility and malleability, making them ideal for applications requiring extensive forming and bending. The distinct metallurgical properties of nickel alloys enhance tool life during machining, whereas copper alloys provide easier shaping but demand slower machining speeds to prevent material deformation.

Environmental Impact and Sustainability

Nickel alloys generally exhibit greater corrosion resistance and durability, leading to longer product lifespans and reduced material waste, which enhances environmental sustainability. Copper alloys, while highly recyclable and conductive, often require more frequent replacement due to lower resistance to environmental degradation, potentially increasing resource consumption and waste. The environmental impact of nickel alloys tends to be lower over a product's lifecycle due to their efficiency and longevity, despite higher initial energy inputs during production.

Choosing the Right Alloy for Your Application

Nickel alloys exhibit exceptional corrosion resistance, high-temperature strength, and excellent mechanical properties, making them ideal for extreme environments such as aerospace and chemical processing. Copper alloys offer superior electrical conductivity, thermal conductivity, and antimicrobial properties, which are advantageous in electrical components, plumbing, and marine applications. Selecting the right alloy depends on factors like operating temperature, corrosion exposure, electrical requirements, and mechanical stress to ensure optimal performance and longevity.

Nickel Alloy vs Copper Alloy Infographic

materialdif.com

materialdif.com