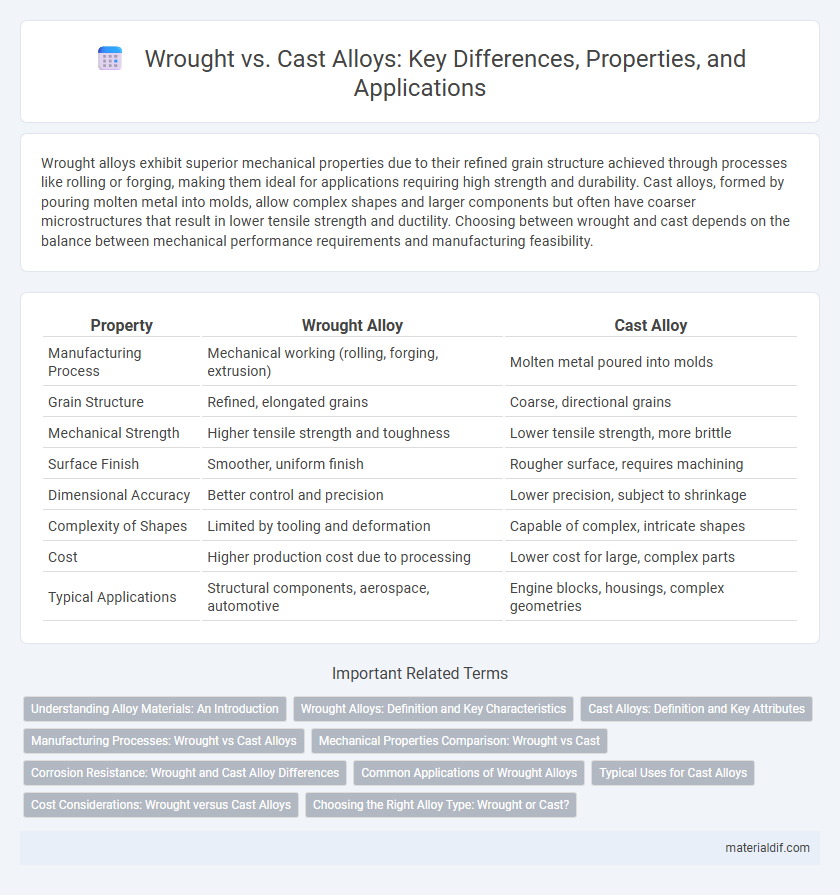

Wrought alloys exhibit superior mechanical properties due to their refined grain structure achieved through processes like rolling or forging, making them ideal for applications requiring high strength and durability. Cast alloys, formed by pouring molten metal into molds, allow complex shapes and larger components but often have coarser microstructures that result in lower tensile strength and ductility. Choosing between wrought and cast depends on the balance between mechanical performance requirements and manufacturing feasibility.

Table of Comparison

| Property | Wrought Alloy | Cast Alloy |

|---|---|---|

| Manufacturing Process | Mechanical working (rolling, forging, extrusion) | Molten metal poured into molds |

| Grain Structure | Refined, elongated grains | Coarse, directional grains |

| Mechanical Strength | Higher tensile strength and toughness | Lower tensile strength, more brittle |

| Surface Finish | Smoother, uniform finish | Rougher surface, requires machining |

| Dimensional Accuracy | Better control and precision | Lower precision, subject to shrinkage |

| Complexity of Shapes | Limited by tooling and deformation | Capable of complex, intricate shapes |

| Cost | Higher production cost due to processing | Lower cost for large, complex parts |

| Typical Applications | Structural components, aerospace, automotive | Engine blocks, housings, complex geometries |

Understanding Alloy Materials: An Introduction

Wrought alloys feature a refined microstructure achieved through mechanical working processes such as rolling or forging, resulting in enhanced strength and toughness compared to cast alloys. Cast alloys are produced by melting and pouring into molds, which often leads to coarser grain structures and potential porosity but allows for complex shapes and cost-effective manufacturing. Understanding these differences is crucial for selecting the appropriate alloy material based on mechanical properties and application requirements.

Wrought Alloys: Definition and Key Characteristics

Wrought alloys are metals that have been mechanically worked through processes such as rolling, forging, or extrusion to shape and strengthen the material. These alloys exhibit superior mechanical properties, including enhanced ductility, toughness, and impact resistance, due to their refined grain structure and reduced porosity. Common examples include wrought aluminum, copper, and steel alloys, which are widely used in structural and automotive applications for their high strength-to-weight ratio and consistent performance.

Cast Alloys: Definition and Key Attributes

Cast alloys are metals that are melted and poured into molds to achieve specific shapes, offering superior design flexibility for complex geometries. These alloys often exhibit excellent wear resistance and vibration damping properties due to their microstructure formed during solidification. Key attributes include good machinability, the ability to produce intricate and large components, and enhanced thermal conductivity compared to wrought alloys.

Manufacturing Processes: Wrought vs Cast Alloys

Wrought alloys undergo mechanical working processes such as rolling, forging, and extrusion, which refine their grain structure, enhancing strength and ductility. Cast alloys are produced by pouring molten metal into molds, allowing complex shapes but often resulting in coarser microstructures with lower mechanical strength. The choice between wrought and cast alloys depends on required mechanical properties, dimensional complexity, and cost-efficiency in manufacturing.

Mechanical Properties Comparison: Wrought vs Cast

Wrought alloys typically exhibit superior mechanical properties compared to cast alloys due to their refined microstructure and directional grain flow, resulting in higher tensile strength, ductility, and fatigue resistance. Cast alloys often have porosity and non-uniform grain structure, which can reduce toughness and impact strength. The mechanical integrity of wrought alloys makes them preferable for applications requiring high performance and structural reliability.

Corrosion Resistance: Wrought and Cast Alloy Differences

Wrought alloys typically exhibit superior corrosion resistance compared to cast alloys due to their refined grain structure and reduced porosity, which minimize sites for corrosion initiation. Cast alloys often have microstructural heterogeneities and higher impurity concentrations that can accelerate corrosion processes. Selecting wrought alloys is advantageous in environments with aggressive chemical exposure, ensuring enhanced longevity and performance.

Common Applications of Wrought Alloys

Wrought alloys are extensively utilized in automotive components, aerospace structures, and construction materials due to their superior mechanical properties and enhanced ductility. These alloys excel in applications requiring precise shaping, such as forging, rolling, and extrusion, which result in improved tensile strength and fatigue resistance. Their widespread use in manufacturing tools, fasteners, and structural frameworks highlights their versatility and reliability in high-performance environments.

Typical Uses for Cast Alloys

Cast alloys are commonly used in complex shapes requiring good fluidity and moldability, such as engine blocks, pump housings, and valve bodies. Their excellent castability makes them ideal for producing components with intricate geometries and internal cavities. Cast alloys also perform well in applications demanding wear resistance and thermal stability, including automotive, aerospace, and industrial machinery parts.

Cost Considerations: Wrought versus Cast Alloys

Wrought alloys generally incur higher manufacturing costs due to extensive deformation processes such as rolling, forging, and extrusion that enhance mechanical properties. Cast alloys offer cost advantages through simpler mold-based production methods, reducing labor and energy expenses while accommodating complex geometries. Material waste tends to be lower in cast alloys, but wrought alloys provide superior mechanical consistency, impacting overall production cost-effectiveness depending on application requirements.

Choosing the Right Alloy Type: Wrought or Cast?

Selecting the appropriate alloy type depends on the desired mechanical properties and manufacturing processes; wrought alloys offer superior strength and ductility due to their deformation and grain refinement, making them ideal for structural applications. Cast alloys provide excellent fluidity and complex shape formation but generally exhibit lower tensile strength and toughness compared to wrought counterparts. Understanding the trade-offs in microstructure and performance characteristics is crucial for optimizing alloy selection in industries such as aerospace, automotive, and construction.

Wrought vs Cast Infographic

materialdif.com

materialdif.com