Alloy 825 exhibits superior resistance to reducing agents and localized corrosion, making it ideal for acidic environments, while Alloy 625 offers outstanding strength and resistance to oxidation at high temperatures. The nickel-copper-molybdenum composition of Alloy 625 provides enhanced structural integrity in harsh marine and chemical processing applications. Selecting between Alloy 825 and Alloy 625 depends on the specific environmental conditions and mechanical requirements of the project.

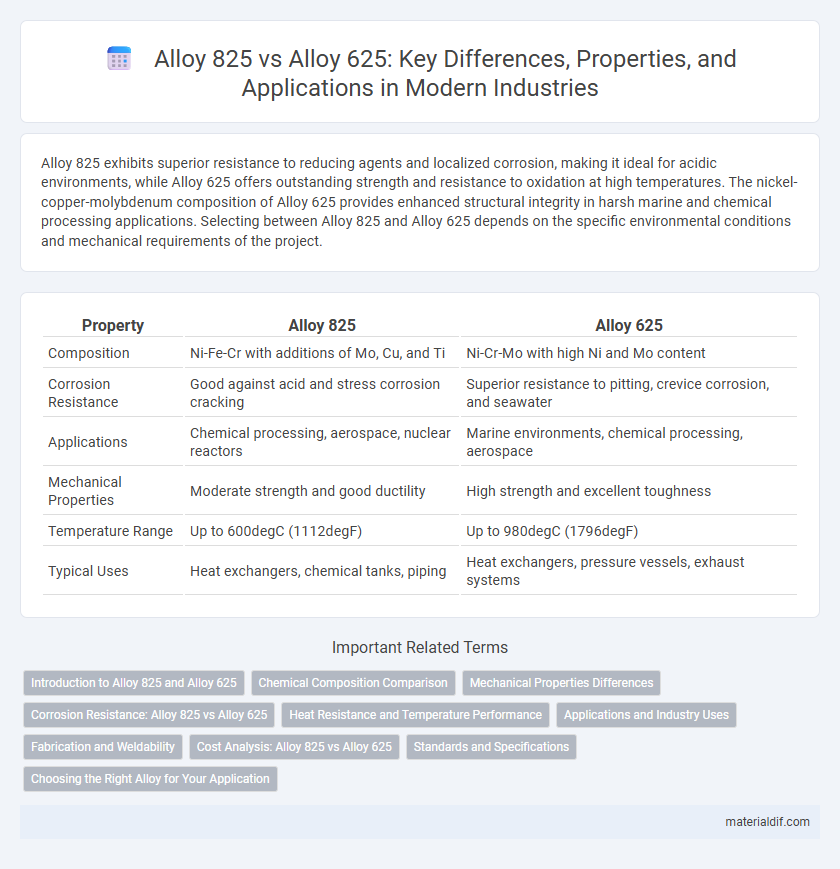

Table of Comparison

| Property | Alloy 825 | Alloy 625 |

|---|---|---|

| Composition | Ni-Fe-Cr with additions of Mo, Cu, and Ti | Ni-Cr-Mo with high Ni and Mo content |

| Corrosion Resistance | Good against acid and stress corrosion cracking | Superior resistance to pitting, crevice corrosion, and seawater |

| Applications | Chemical processing, aerospace, nuclear reactors | Marine environments, chemical processing, aerospace |

| Mechanical Properties | Moderate strength and good ductility | High strength and excellent toughness |

| Temperature Range | Up to 600degC (1112degF) | Up to 980degC (1796degF) |

| Typical Uses | Heat exchangers, chemical tanks, piping | Heat exchangers, pressure vessels, exhaust systems |

Introduction to Alloy 825 and Alloy 625

Alloy 825 is a nickel-iron-chromium alloy known for its exceptional resistance to corrosion in a wide range of chemical environments, especially in reducing and mildly oxidizing conditions, making it ideal for applications in chemical processing and aerospace industries. Alloy 625, primarily composed of nickel with significant amounts of chromium, molybdenum, and iron, offers superior strength and outstanding resistance to pitting, stress corrosion cracking, and oxidation, which makes it suitable for marine, nuclear, and chemical environments. Both alloys are valued for their high-performance corrosion resistance but differ in composition and specific resistance properties tailored to specialized industrial uses.

Chemical Composition Comparison

Alloy 825 primarily contains 38-46% nickel, 19-23% chromium, 2-3% molybdenum, and iron as the balance, with significant amounts of copper (1-3%) to enhance resistance to reducing acids. Alloy 625 offers a higher nickel content of 58% minimum, 20-23% chromium, 8-10% molybdenum, and niobium (4%) which improves strength and corrosion resistance in harsh environments. The increased molybdenum and niobium in Alloy 625 provide superior pitting and crevice corrosion resistance compared to Alloy 825's higher copper content designed for acid environments.

Mechanical Properties Differences

Alloy 825 offers higher tensile strength and better resistance to stress corrosion cracking compared to Alloy 625, making it ideal for aggressive chemical environments. Alloy 625, however, exhibits superior creep and fatigue resistance, which supports long-term high-temperature applications. Both alloys maintain excellent corrosion resistance, but their mechanical properties dictate specific industrial uses.

Corrosion Resistance: Alloy 825 vs Alloy 625

Alloy 825 exhibits excellent resistance to reducing and mildly oxidizing environments, showing strong performance against stress corrosion cracking, sulphuric acid, and phosphoric acid. Alloy 625 offers superior resistance to a wider range of corrosive environments, including chloride ions and highly oxidizing acids, due to its high nickel, molybdenum, and niobium content. In marine and chemical processing applications, Alloy 625 is generally preferred for its enhanced pitting, crevice corrosion, and stress corrosion cracking resistance compared to Alloy 825.

Heat Resistance and Temperature Performance

Alloy 625 demonstrates superior heat resistance and temperature performance compared to Alloy 825, maintaining structural integrity at temperatures up to 982degC (1800degF) versus Alloy 825's limit near 650degC (1200degF). The high nickel and molybdenum content in Alloy 625 enhances its oxidation and corrosion resistance in high-temperature environments, making it ideal for aerospace and chemical processing applications. Alloy 825, while corrosion-resistant, is better suited for moderate temperature operations where cost efficiency is prioritized.

Applications and Industry Uses

Alloy 825 is widely used in chemical processing, pollution control, and marine environments due to its exceptional resistance to sulfuric acid and chloride-induced corrosion. Alloy 625 finds extensive application in aerospace, nuclear reactors, and offshore oil and gas industries, valued for its high strength, excellent fatigue resistance, and superior performance in high-temperature and oxidizing environments. Both alloys serve critical roles in industrial sectors requiring durable, corrosion-resistant materials but differ mainly in their specific resistance properties and mechanical strength tailored to their applications.

Fabrication and Weldability

Alloy 825 offers excellent fabrication properties with good ductility and formability, making it suitable for complex shapes and heavy-duty applications. Alloy 625 provides superior weldability due to its high strength and resistance to carbides precipitation, minimizing the risk of weld cracking in high-temperature environments. Both alloys demonstrate strong corrosion resistance, but Alloy 625's weld characteristics often lead to wider use in demanding welding operations.

Cost Analysis: Alloy 825 vs Alloy 625

Alloy 825 offers a more cost-effective solution compared to Alloy 625, primarily due to its lower nickel and molybdenum content, which reduces raw material expenses. Despite Alloy 625's superior corrosion resistance and mechanical properties, the price difference can be significant for large-scale projects, making Alloy 825 a preferred choice when budget constraints exist. Evaluating total lifecycle costs, including maintenance and replacement, is essential to determine the optimal alloy for specific industrial applications.

Standards and Specifications

Alloy 825 adheres to ASTM B575 and UNS N08825 standards, primarily used in chemical processing and aerospace for its resistance to acidic environments. Alloy 625 meets ASTM B443 and UNS N06625 specifications, favored in marine and nuclear sectors due to superior strength and corrosion resistance at high temperatures. Both alloys comply with ASME Boiler and Pressure Vessel Code, with Alloy 625 offering enhanced performance in extreme conditions compared to Alloy 825.

Choosing the Right Alloy for Your Application

Alloy 825 offers excellent resistance to sulfuric acid and high stress corrosion cracking, making it ideal for chemical processing and marine environments. Alloy 625 provides superior strength and outstanding resistance to pitting, crevice corrosion, and high temperatures, suitable for aerospace and gas turbine applications. Selecting the right alloy depends on the specific environmental conditions and mechanical stress factors present in your application.

Alloy 825 vs Alloy 625 Infographic

materialdif.com

materialdif.com