Powder metallurgy alloys offer superior microstructural homogeneity and finer grain size compared to ingot metallurgy alloys, resulting in enhanced mechanical properties and wear resistance. The powder metallurgy process minimizes segregation and porosity commonly found in ingot alloys due to controlled particle distribution and sintering techniques. As a result, powder metallurgy alloys are ideal for complex shapes and high-performance applications requiring precise control over material characteristics.

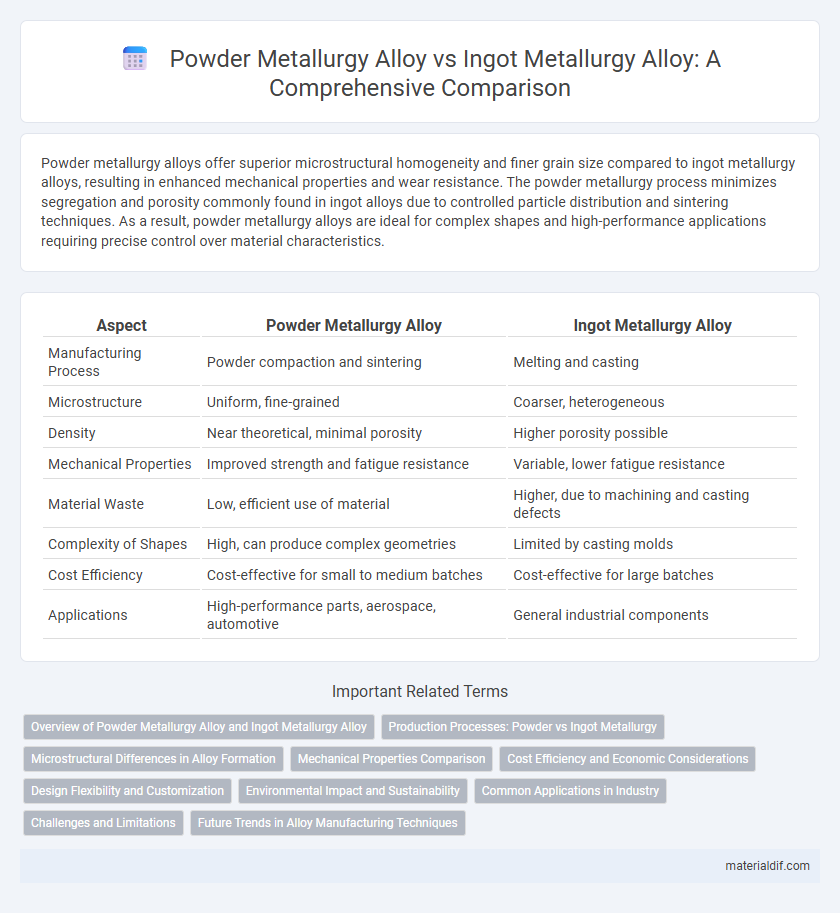

Table of Comparison

| Aspect | Powder Metallurgy Alloy | Ingot Metallurgy Alloy |

|---|---|---|

| Manufacturing Process | Powder compaction and sintering | Melting and casting |

| Microstructure | Uniform, fine-grained | Coarser, heterogeneous |

| Density | Near theoretical, minimal porosity | Higher porosity possible |

| Mechanical Properties | Improved strength and fatigue resistance | Variable, lower fatigue resistance |

| Material Waste | Low, efficient use of material | Higher, due to machining and casting defects |

| Complexity of Shapes | High, can produce complex geometries | Limited by casting molds |

| Cost Efficiency | Cost-effective for small to medium batches | Cost-effective for large batches |

| Applications | High-performance parts, aerospace, automotive | General industrial components |

Overview of Powder Metallurgy Alloy and Ingot Metallurgy Alloy

Powder metallurgy alloy is fabricated by compressing and sintering fine metal powders, allowing precise control over composition and microstructure for improved mechanical properties and reduced waste. Ingot metallurgy alloy involves melting and casting molten metal into ingots, followed by shaping through rolling or forging, which often results in coarser grain structures and potential segregation. Powder metallurgy alloys offer superior homogeneity and wear resistance compared to traditional ingot metallurgy alloys, making them ideal for complex and high-performance applications.

Production Processes: Powder vs Ingot Metallurgy

Powder metallurgy alloys are produced by compacting metal powders under high pressure and sintering them at elevated temperatures, enabling precise control over composition and microstructure. Ingot metallurgy alloys involve melting raw materials followed by casting and solidification, which can lead to segregation and anisotropy in the final product. The powder metallurgy process offers advantages in material utilization, reduced waste, and the ability to fabricate complex shapes not achievable through ingot metallurgy.

Microstructural Differences in Alloy Formation

Powder metallurgy alloys exhibit a more uniform microstructure with finer grain sizes and reduced segregation compared to ingot metallurgy alloys, which often display coarse grains and microsegregation due to slower cooling rates. The rapid solidification and compaction processes in powder metallurgy enhance homogeneity and promote the formation of metastable phases not typically found in ingot metallurgy. This refined microstructure improves mechanical properties such as strength, hardness, and wear resistance in powder metallurgy alloys.

Mechanical Properties Comparison

Powder metallurgy alloys exhibit superior mechanical properties compared to ingot metallurgy alloys due to their finer and more uniform microstructure, which enhances strength and hardness. The controlled cooling rates and minimal grain growth in powder metallurgy result in improved fatigue resistance and wear performance. In contrast, ingot metallurgy alloys often show coarser grains and increased segregation, leading to lower tensile strength and reduced ductility.

Cost Efficiency and Economic Considerations

Powder metallurgy alloys offer superior cost efficiency compared to ingot metallurgy alloys due to reduced material waste and lower energy consumption during production. The near-net shape manufacturing process in powder metallurgy minimizes machining expenses and shortens lead times, resulting in overall economic advantages. Ingot metallurgy alloys typically incur higher costs driven by extensive machining, material losses, and longer production cycles.

Design Flexibility and Customization

Powder metallurgy alloys offer superior design flexibility and customization compared to ingot metallurgy alloys due to their ability to form complex geometries and intricate shapes without extensive machining. This process allows precise control over alloy composition at the microscopic level, enabling tailored material properties that meet specific performance requirements. Ingot metallurgy alloys, while robust, are limited by casting and forging constraints, resulting in fewer opportunities for fine-tuning microstructures and component design.

Environmental Impact and Sustainability

Powder metallurgy alloys typically offer superior environmental benefits compared to ingot metallurgy alloys due to reduced material waste and lower energy consumption during production. The precise control over powder particle size and composition enhances resource efficiency and minimizes emissions, contributing to more sustainable manufacturing processes. Ingot metallurgy alloys often require extensive melting and casting, leading to higher energy use and increased greenhouse gas emissions, posing greater challenges for environmental sustainability.

Common Applications in Industry

Powder metallurgy alloys are widely used in automotive components, aerospace parts, and cutting tools due to their precise microstructure control and enhanced wear resistance. Ingot metallurgy alloys find common applications in large structural components, shipbuilding, and heavy machinery, benefiting from their excellent mechanical properties and ease of casting. Both methods serve critical roles in manufacturing, with powder metallurgy favored for complex shapes and ingot metallurgy for bulk materials.

Challenges and Limitations

Powder metallurgy alloys face challenges such as porosity, non-uniform microstructure, and limited part size due to compaction and sintering constraints. Ingot metallurgy alloys often suffer from segregation, coarse grains, and lower mechanical properties resulting from slower cooling rates and solidification defects. Both methods struggle with achieving consistent alloy homogeneity and repeatable mechanical performance, impacting their suitability for critical aerospace and automotive applications.

Future Trends in Alloy Manufacturing Techniques

Powder metallurgy alloys offer superior uniformity and refined microstructure, enabling enhanced mechanical properties and reduced material waste compared to ingot metallurgy alloys. Future trends emphasize additive manufacturing integrations and advanced sintering technologies to produce complex geometries with minimal defects. Innovations in alloy composition and nanoparticle reinforcement further drive performance improvements and sustainability in alloy manufacturing.

Powder metallurgy alloy vs Ingot metallurgy alloy Infographic

materialdif.com

materialdif.com