Tool steel offers superior hardness, wear resistance, and toughness compared to structural steel, making it ideal for precision tools and dies. Structural steel prioritizes strength and ductility, designed to support loads and resist bending in construction and infrastructure applications. Choosing between tool steel and structural steel depends on the specific demands for durability, shape retention, and mechanical performance in the intended use.

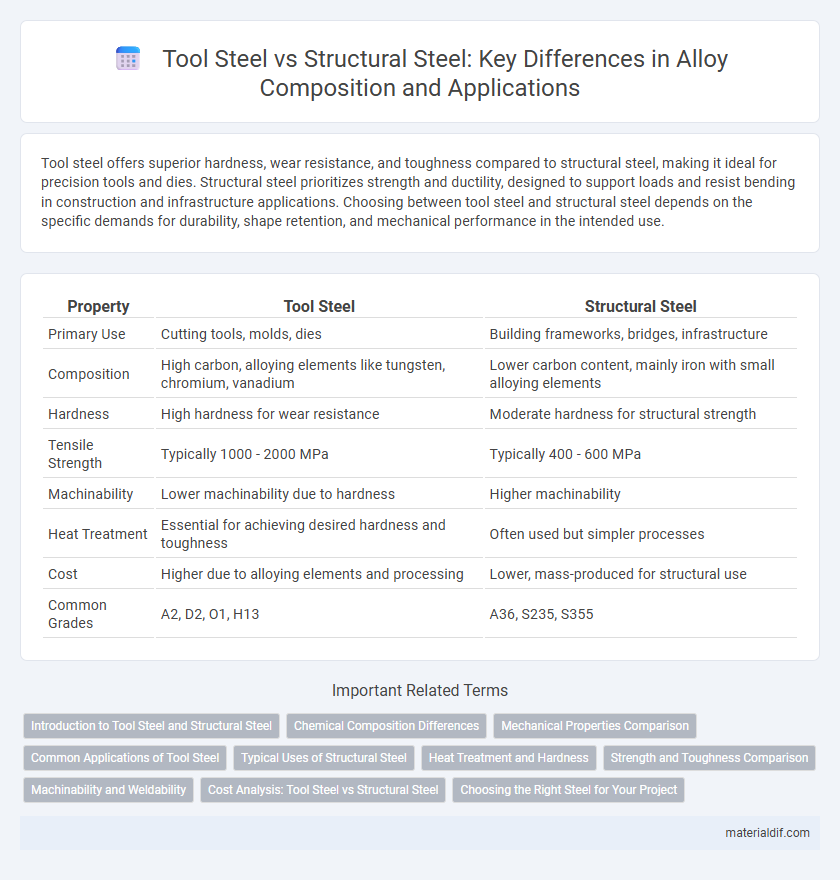

Table of Comparison

| Property | Tool Steel | Structural Steel |

|---|---|---|

| Primary Use | Cutting tools, molds, dies | Building frameworks, bridges, infrastructure |

| Composition | High carbon, alloying elements like tungsten, chromium, vanadium | Lower carbon content, mainly iron with small alloying elements |

| Hardness | High hardness for wear resistance | Moderate hardness for structural strength |

| Tensile Strength | Typically 1000 - 2000 MPa | Typically 400 - 600 MPa |

| Machinability | Lower machinability due to hardness | Higher machinability |

| Heat Treatment | Essential for achieving desired hardness and toughness | Often used but simpler processes |

| Cost | Higher due to alloying elements and processing | Lower, mass-produced for structural use |

| Common Grades | A2, D2, O1, H13 | A36, S235, S355 |

Introduction to Tool Steel and Structural Steel

Tool steel is a high-alloy steel designed for manufacturing cutting tools, dies, and molds, characterized by its hardness, wear resistance, and ability to retain a sharp edge at high temperatures. Structural steel primarily consists of carbon steel with controlled alloying elements, engineered for strength and durability in construction frameworks, bridges, and heavy-duty machinery. The distinct compositions of tool steel and structural steel reflect their specialized applications, with tool steel emphasizing hardness and toughness, while structural steel prioritizes load-bearing capacity and weldability.

Chemical Composition Differences

Tool steel contains higher percentages of carbon, chromium, vanadium, and molybdenum compared to structural steel, enhancing hardness and wear resistance. Structural steel has a relatively lower carbon content with more emphasis on iron, manganese, and small amounts of silicon, optimizing strength and ductility for construction applications. The presence of alloying elements like tungsten and cobalt in tool steel improves heat resistance and cutting performance, which are minimal or absent in structural steel grades.

Mechanical Properties Comparison

Tool steel exhibits higher hardness, tensile strength, and wear resistance compared to structural steel, making it ideal for cutting and shaping applications. Structural steel offers greater ductility and toughness, providing superior impact resistance and flexibility under load conditions. The mechanical properties of tool steel prioritize durability and precision, whereas structural steel emphasizes load-bearing capacity and structural integrity.

Common Applications of Tool Steel

Tool steel is predominantly used in applications requiring high hardness, wear resistance, and the ability to retain a sharp cutting edge, such as cutting tools, dies, molds, and punches. It is essential for manufacturing tools that undergo high stress and temperature, including drills, knives, and industrial blades. Unlike structural steel, which is designed for strength and load-bearing in construction and infrastructure, tool steel is optimized for precision and durability in machining and forming operations.

Typical Uses of Structural Steel

Structural steel is primarily used in construction for building frameworks, bridges, and infrastructure due to its high strength, durability, and versatility. It supports heavy loads and withstands environmental stress in buildings, towers, and industrial facilities. Common applications include beams, columns, and reinforcement in large-scale civil engineering projects.

Heat Treatment and Hardness

Tool steel exhibits superior hardness and wear resistance compared to structural steel due to specialized heat treatment processes such as quenching and tempering, which enhance its ability to retain sharp edges under high-stress conditions. Structural steel, while more ductile and tougher, undergoes less intensive heat treatment, primarily normalizing or annealing, resulting in lower hardness but improved flexibility and impact resistance. The heat treatment of tool steel typically achieves hardness levels above 60 HRC, whereas structural steel hardness rarely exceeds 30 HRC, reflecting their distinct applications in precision tooling versus load-bearing frameworks.

Strength and Toughness Comparison

Tool steel exhibits higher hardness and wear resistance compared to structural steel due to its alloying elements like tungsten, molybdenum, and vanadium, enhancing its strength for cutting and shaping tools. Structural steel, while generally less hard, offers superior toughness and ductility, allowing it to absorb impact and resist fracture in construction applications. The balance between strength and toughness varies significantly, with tool steel optimized for hardness and load-bearing capacity under stress, whereas structural steel emphasizes resilience and flexibility.

Machinability and Weldability

Tool steel exhibits superior machinability due to its hardened microstructure and alloying elements like tungsten and chromium that enhance wear resistance, while structural steel offers better weldability because of its lower carbon content and simpler composition. The high hardness of tool steel often requires specialized cutting tools and slower machining speeds, whereas structural steel responds well to standard welding techniques such as MIG and TIG welding. Choosing between these steels depends heavily on the balance between machining complexity and welding ease in manufacturing processes.

Cost Analysis: Tool Steel vs Structural Steel

Tool steel generally incurs higher costs than structural steel due to its alloying elements such as tungsten, molybdenum, and vanadium that enhance hardness and wear resistance. Structural steel is more economical, benefiting from simpler composition and mass production efficiencies ideal for large-scale construction projects. When budgeting, tool steel suits applications demanding durability and precision despite its price, while structural steel is cost-effective for frameworks and load-bearing structures.

Choosing the Right Steel for Your Project

Tool steel offers superior hardness, wear resistance, and heat resistance, making it ideal for cutting tools, molds, and dies that require precision and durability. Structural steel provides excellent tensile strength, ductility, and weldability, suited for construction frameworks, bridges, and heavy machinery. Selecting the right steel depends on project demands: tool steel excels in high-stress, abrasion-prone applications, whereas structural steel is preferred for load-bearing and flexible structural requirements.

Tool steel vs Structural steel Infographic

materialdif.com

materialdif.com