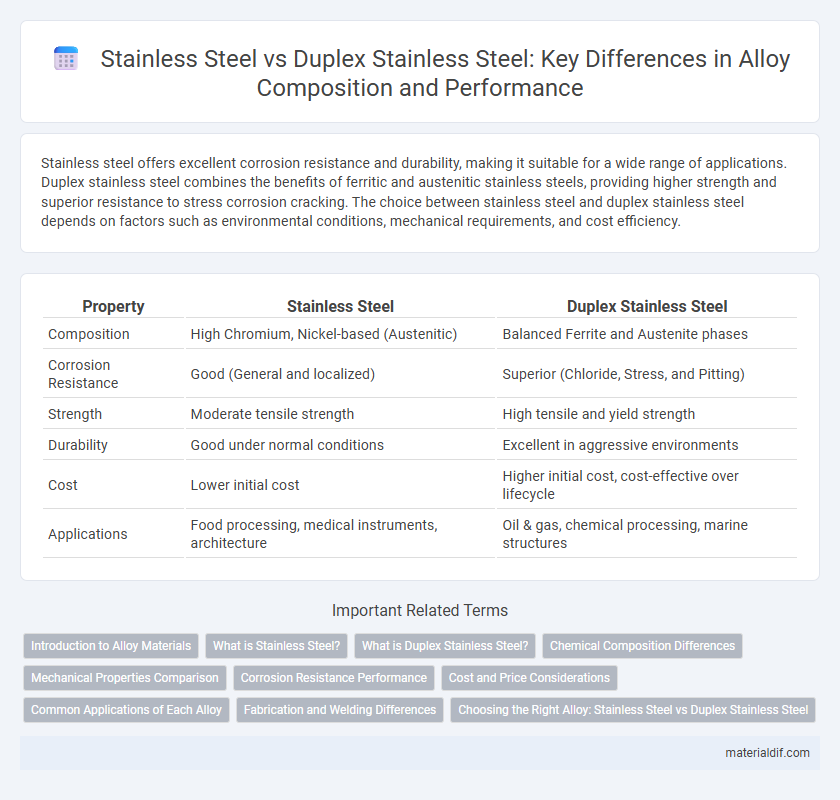

Stainless steel offers excellent corrosion resistance and durability, making it suitable for a wide range of applications. Duplex stainless steel combines the benefits of ferritic and austenitic stainless steels, providing higher strength and superior resistance to stress corrosion cracking. The choice between stainless steel and duplex stainless steel depends on factors such as environmental conditions, mechanical requirements, and cost efficiency.

Table of Comparison

| Property | Stainless Steel | Duplex Stainless Steel |

|---|---|---|

| Composition | High Chromium, Nickel-based (Austenitic) | Balanced Ferrite and Austenite phases |

| Corrosion Resistance | Good (General and localized) | Superior (Chloride, Stress, and Pitting) |

| Strength | Moderate tensile strength | High tensile and yield strength |

| Durability | Good under normal conditions | Excellent in aggressive environments |

| Cost | Lower initial cost | Higher initial cost, cost-effective over lifecycle |

| Applications | Food processing, medical instruments, architecture | Oil & gas, chemical processing, marine structures |

Introduction to Alloy Materials

Stainless steel alloys, primarily composed of iron, chromium, and nickel, offer excellent corrosion resistance and mechanical strength for diverse applications. Duplex stainless steel combines austenitic and ferritic microstructures, enhancing resistance to stress corrosion cracking and improving toughness. The alloy choice depends on environmental exposure, with duplex grades favored in aggressive conditions due to their superior chloride resistance and durability.

What is Stainless Steel?

Stainless steel is a corrosion-resistant alloy primarily composed of iron, chromium (minimum 10.5%), and varying amounts of nickel, molybdenum, and other elements to enhance durability and resistance to oxidation. Its microstructure categorizes it into types such as austenitic, ferritic, martensitic, and duplex, each offering specific mechanical properties and corrosion resistance suitable for diverse industrial applications. The chromium content forms a passive oxide layer on the surface, providing stainless steel with its distinctive rust-resistant performance compared to conventional carbon steel.

What is Duplex Stainless Steel?

Duplex stainless steel is a hybrid alloy combining austenitic and ferritic stainless steels, offering enhanced strength, corrosion resistance, and durability compared to standard stainless steel grades. Its unique microstructure consists of approximately equal proportions of ferrite and austenite phases, providing superior resistance to stress corrosion cracking and pitting in aggressive environments. Commonly used in chemical processing, oil and gas, and marine applications, duplex stainless steel balances toughness with corrosion resistance, making it ideal for demanding industrial conditions.

Chemical Composition Differences

Stainless Steel primarily contains 10.5-12% chromium with minimal nickel, providing corrosion resistance and moderate strength, while Duplex Stainless Steel combines approximately 22-25% chromium and 5-7% nickel with added molybdenum, enhancing pitting and crevice corrosion resistance. The higher chromium and molybdenum content in Duplex alloys offers superior protection in aggressive chemical environments compared to standard Stainless Steel. The balanced austenitic-ferritic microstructure in Duplex Stainless Steel results from this complex chemical composition, delivering improved mechanical properties and corrosion resistance.

Mechanical Properties Comparison

Stainless steel offers excellent corrosion resistance and moderate mechanical strength, with tensile strength typically ranging from 515 to 720 MPa and good ductility. Duplex stainless steel combines austenitic and ferritic microstructures, providing superior mechanical properties such as higher tensile strength between 700 and 900 MPa and improved toughness and fatigue resistance. The balanced phase structure of duplex stainless steel results in enhanced yield strength and stress corrosion cracking resistance compared to traditional stainless steel grades.

Corrosion Resistance Performance

Duplex stainless steel exhibits superior corrosion resistance compared to traditional stainless steel due to its balanced microstructure of austenite and ferrite phases, which enhances resistance to stress corrosion cracking and pitting. This alloy is particularly effective in chloride-rich environments and aggressive marine conditions where standard stainless steel grades like 304 or 316 may fail. The enhanced chromium, molybdenum, and nitrogen content in duplex stainless steel significantly improves its durability against localized corrosion and extends the lifespan of critical infrastructure.

Cost and Price Considerations

Stainless steel typically costs less upfront than duplex stainless steel due to its simpler composition and widespread availability, making it a budget-friendly choice for many applications. Duplex stainless steel, with its superior corrosion resistance and higher strength, commands a higher price but offers long-term savings through reduced maintenance and longer service life. Evaluating project requirements and lifecycle expenses is crucial when considering the cost-effectiveness of stainless steel versus duplex stainless steel alloys.

Common Applications of Each Alloy

Stainless steel is widely used in kitchenware, medical instruments, and architectural structures due to its excellent corrosion resistance and aesthetic appeal. Duplex stainless steel finds frequent applications in chemical processing, oil and gas industries, and marine environments, benefiting from its superior strength and resistance to stress corrosion cracking. Both alloys are essential in construction, with stainless steel favored for exterior cladding and duplex stainless steel used in demanding environments requiring high durability.

Fabrication and Welding Differences

Stainless steel offers excellent corrosion resistance and ease of fabrication with standard welding techniques, commonly using TIG or MIG welding, whereas duplex stainless steel requires more specialized welding procedures to maintain its dual-phase microstructure and prevent intermetallic phase formation. Duplex stainless steel has higher strength and enhanced resistance to stress corrosion cracking but demands precise control of heat input and cooling rates during welding to avoid phase imbalance and reduce embrittlement risks. Fabrication of duplex stainless steel typically involves stringent post-weld heat treatment or solution annealing, unlike standard stainless steel, which usually does not require such extensive treatment.

Choosing the Right Alloy: Stainless Steel vs Duplex Stainless Steel

Stainless steel offers excellent corrosion resistance and formability, making it ideal for general-purpose applications, while duplex stainless steel combines austenitic and ferritic properties, providing superior strength and resistance to stress corrosion cracking. Duplex stainless steel typically contains higher levels of chromium, molybdenum, and nitrogen, enhancing its performance in aggressive environments such as marine or chemical processing. Selecting the appropriate alloy depends on factors like mechanical strength requirements, corrosion environment, and cost considerations, with duplex stainless steel favored for demanding conditions requiring robustness and longevity.

Stainless Steel vs Duplex Stainless Steel Infographic

materialdif.com

materialdif.com