Powder metallurgy offers precise control over alloy composition and microstructure, enabling the production of complex shapes with minimal waste. Conventional processing methods typically involve casting or forging, which can result in coarser grain structures and increased material loss due to machining. The powder metallurgy process enhances mechanical properties and reduces processing steps, making it ideal for high-performance alloy components.

Table of Comparison

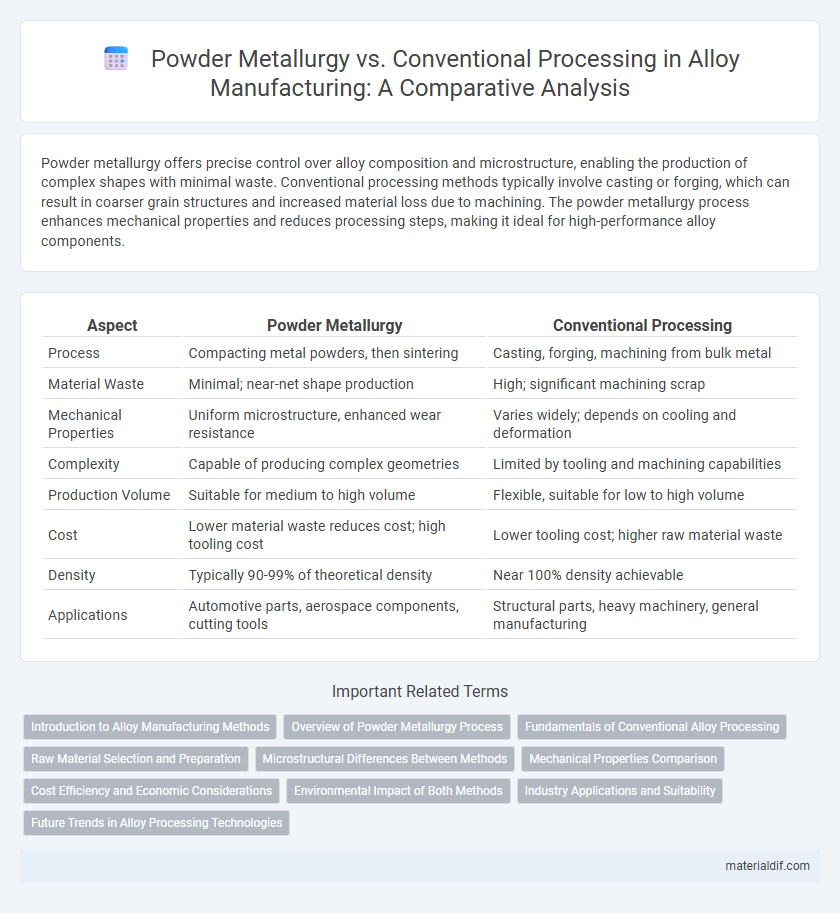

| Aspect | Powder Metallurgy | Conventional Processing |

|---|---|---|

| Process | Compacting metal powders, then sintering | Casting, forging, machining from bulk metal |

| Material Waste | Minimal; near-net shape production | High; significant machining scrap |

| Mechanical Properties | Uniform microstructure, enhanced wear resistance | Varies widely; depends on cooling and deformation |

| Complexity | Capable of producing complex geometries | Limited by tooling and machining capabilities |

| Production Volume | Suitable for medium to high volume | Flexible, suitable for low to high volume |

| Cost | Lower material waste reduces cost; high tooling cost | Lower tooling cost; higher raw material waste |

| Density | Typically 90-99% of theoretical density | Near 100% density achievable |

| Applications | Automotive parts, aerospace components, cutting tools | Structural parts, heavy machinery, general manufacturing |

Introduction to Alloy Manufacturing Methods

Powder metallurgy offers precise control over alloy composition and microstructure, enabling the production of complex shapes with minimal material waste. Conventional processing methods, such as casting and forging, involve melting and shaping alloys but often face limitations in achieving uniform microstructures and intricate geometries. Selecting the appropriate alloy manufacturing method depends on desired mechanical properties, production volume, and cost considerations.

Overview of Powder Metallurgy Process

Powder metallurgy involves compacting metal powders into desired shapes followed by sintering at high temperatures to achieve solid-state bonding, offering precise control over material properties and microstructure. This process enables production of complex geometries with minimal machining and reduced material waste compared to conventional processing methods such as casting or forging. The ability to tailor alloy compositions at the powder stage enhances performance characteristics like strength, wear resistance, and porosity control critical for advanced alloy applications.

Fundamentals of Conventional Alloy Processing

Conventional alloy processing involves casting, forging, and rolling methods that shape metals through mechanical deformation and thermal treatment to achieve desired microstructures and mechanical properties. This process relies on melting and solidification stages, allowing control over grain size, phase distribution, and defect reduction in the alloy structure. Unlike powder metallurgy, conventional processing often results in coarser microstructures but enables large-scale production with established industrial techniques.

Raw Material Selection and Preparation

Powder metallurgy uses fine metallic powders as raw materials, enabling precise control over composition and reducing waste during processing. Conventional processing typically relies on ingots or cast blocks, which require extensive melting and refining steps, often leading to higher energy consumption and material losses. The selection and preparation of powders in powder metallurgy allow for enhanced uniformity and tailored microstructures that improve mechanical properties compared to traditional billet-based methods.

Microstructural Differences Between Methods

Powder metallurgy produces finer, more uniform microstructures by consolidating metal powders, leading to enhanced mechanical properties and reduced porosity compared to conventional processing, which involves melting and solidification that can cause grain coarsening and segregation. The fine microstructure in powder metallurgy alloys improves wear resistance and fatigue strength, while conventional processing often results in dendritic structures and inhomogeneous phase distribution. These microstructural differences significantly impact the performance, machinability, and reliability of alloy components in various industrial applications.

Mechanical Properties Comparison

Powder metallurgy produces alloys with finer microstructures, resulting in enhanced tensile strength and hardness compared to conventional processing methods. The controlled particle size distribution in powder metallurgy improves sintering behavior, leading to superior wear resistance and fatigue performance. Conventional processing often yields coarser grains, reducing mechanical properties such as impact toughness and dimensional stability.

Cost Efficiency and Economic Considerations

Powder metallurgy offers significant cost efficiency over conventional processing by minimizing material waste and reducing machining requirements, which lowers overall production expenses. This method enables near-net shape manufacturing, decreasing energy consumption and shortening production cycles, translating into economic advantages for large-scale alloy production. Cost savings also arise from the potential to use lower-grade raw materials while maintaining mechanical properties, enhancing the economic feasibility of complex alloy components.

Environmental Impact of Both Methods

Powder metallurgy reduces environmental impact by minimizing material waste and energy consumption compared to conventional alloy processing, which often involves extensive machining and higher energy use. The powder metallurgy process generates less greenhouse gas emissions due to lower processing temperatures and shorter cycle times, contributing to a smaller carbon footprint. Conventional methods typically rely on bulk material removal, leading to increased scrap production and resource inefficiency, making powder metallurgy a more sustainable choice for alloy manufacturing.

Industry Applications and Suitability

Powder metallurgy enables the production of complex-shaped alloy components with superior material utilization and tailored microstructures, making it ideal for aerospace, automotive, and medical industries requiring high-performance, lightweight parts. Conventional processing methods, such as casting and forging, are better suited for large-scale manufacturing of simpler geometries with established mechanical properties, commonly used in construction, heavy machinery, and general engineering applications. The choice between powder metallurgy and conventional processing depends on factors like production volume, component complexity, and performance requirements within the specific industrial sector.

Future Trends in Alloy Processing Technologies

Future trends in alloy processing technologies emphasize the growth of powder metallurgy due to its enhanced control over microstructure and alloy composition, enabling superior mechanical properties and material efficiency compared to conventional casting and forging. Innovations in additive manufacturing and advanced sintering techniques further accelerate the adoption of powder metallurgy, promoting sustainability through reduced waste and energy consumption. Integration of computational materials science and AI-driven process optimization is expected to revolutionize alloy design and manufacturing precision in forthcoming powder metallurgy applications.

Powder Metallurgy vs Conventional Processing Infographic

materialdif.com

materialdif.com