Age hardening increases an alloy's strength by precipitating fine particles within the metal matrix, which blocks dislocation movement and enhances hardness over time. Solution treating dissolves alloying elements into a single-phase solid solution by heating the alloy to a high temperature, followed by rapid cooling to retain a uniform distribution. These processes differ in that solution treating prepares the alloy for subsequent age hardening by homogenizing its structure, while age hardening develops the mechanical properties through controlled precipitation.

Table of Comparison

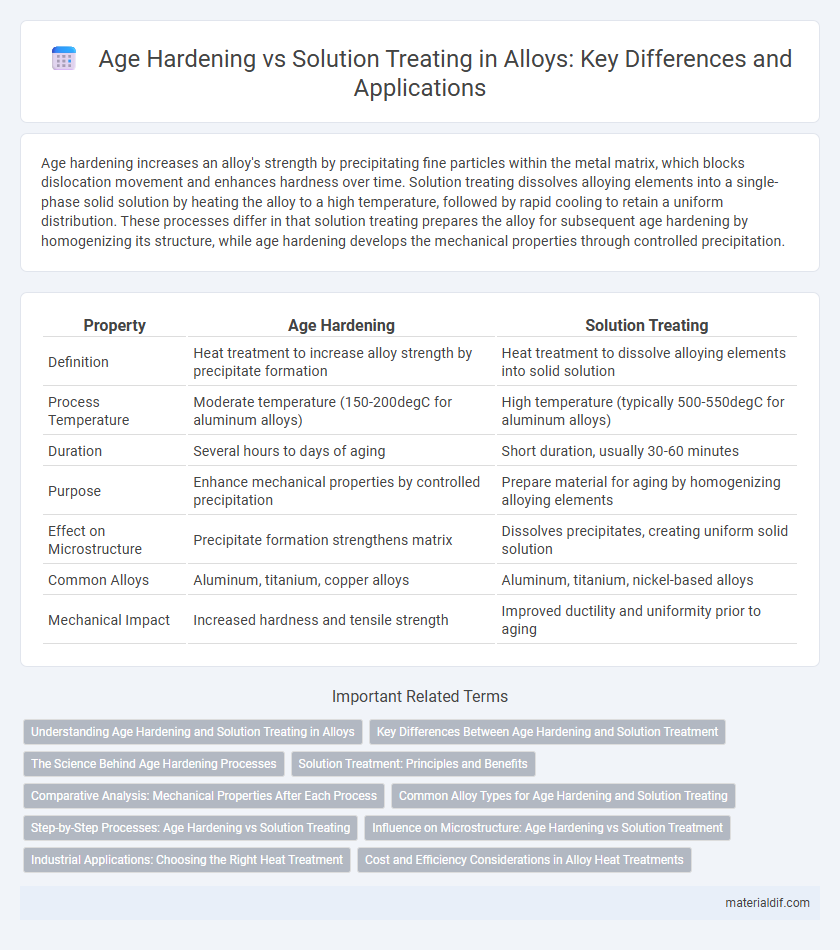

| Property | Age Hardening | Solution Treating |

|---|---|---|

| Definition | Heat treatment to increase alloy strength by precipitate formation | Heat treatment to dissolve alloying elements into solid solution |

| Process Temperature | Moderate temperature (150-200degC for aluminum alloys) | High temperature (typically 500-550degC for aluminum alloys) |

| Duration | Several hours to days of aging | Short duration, usually 30-60 minutes |

| Purpose | Enhance mechanical properties by controlled precipitation | Prepare material for aging by homogenizing alloying elements |

| Effect on Microstructure | Precipitate formation strengthens matrix | Dissolves precipitates, creating uniform solid solution |

| Common Alloys | Aluminum, titanium, copper alloys | Aluminum, titanium, nickel-based alloys |

| Mechanical Impact | Increased hardness and tensile strength | Improved ductility and uniformity prior to aging |

Understanding Age Hardening and Solution Treating in Alloys

Age hardening increases alloy strength by forming fine precipitates within the metal matrix during controlled cooling, enhancing hardness and mechanical properties. Solution treating involves heating the alloy to dissolve precipitates into a solid solution, followed by rapid quenching to retain a supersaturated state for subsequent age hardening. Understanding the interplay between solution treating and age hardening optimizes alloy performance by tailoring microstructure and hardness.

Key Differences Between Age Hardening and Solution Treatment

Age hardening enhances alloy strength by precipitating finely dispersed particles within the metal matrix after solution treatment and quenching, whereas solution treating involves heating the alloy to dissolve precipitates fully followed by rapid cooling to form a supersaturated solid solution. Age hardening primarily improves mechanical properties such as hardness and tensile strength over time through controlled heating during aging, while solution treating prepares the alloy for subsequent processes by homogenizing the microstructure. The key difference lies in their functional purpose: solution treating resets the microstructure, and age hardening develops peak strength through precipitation.

The Science Behind Age Hardening Processes

Age hardening, also known as precipitation hardening, involves the controlled formation of fine, uniformly distributed precipitates within an alloy matrix, which impedes dislocation movement and enhances mechanical strength. Solution treating dissolves alloying elements into a single-phase solid solution at high temperatures, followed by rapid quenching to retain a supersaturated solid solution that serves as the starting point for subsequent age hardening. The science behind age hardening centers on nucleation, growth, and coarsening of precipitates, optimizing particle size and distribution to maximize strength and hardness in alloys such as aluminum, titanium, and nickel-based superalloys.

Solution Treatment: Principles and Benefits

Solution treatment involves heating an alloy to a high temperature where its constituent elements dissolve into a solid solution, followed by rapid quenching to retain this homogeneous structure. This process enhances the alloy's mechanical properties by refining grain structure, improving corrosion resistance, and enabling uniform precipitation during subsequent aging. Compared to age hardening, solution treatment provides a stable baseline microstructure that maximizes strength and ductility through controlled phase distribution.

Comparative Analysis: Mechanical Properties After Each Process

Age hardening significantly enhances an alloy's yield strength and tensile strength by promoting precipitation of fine particles that obstruct dislocation motion, whereas solution treating primarily dissolves alloying elements to create a homogeneous single-phase structure. Post age hardening, alloys typically exhibit higher hardness and improved fatigue resistance compared to solution treated samples, which show superior ductility and toughness due to their uniform microstructure. The mechanical properties after either process depend on the specific alloy system, temperature profiles, and duration, making the combination of both treatments essential to optimize performance in aerospace and automotive applications.

Common Alloy Types for Age Hardening and Solution Treating

Common alloy types for age hardening include aluminum alloys such as 2000, 6000, and 7000 series, which benefit from precipitation strengthening to enhance mechanical properties. Solution treating is typically applied to stainless steels like 300 and 400 series and nickel-based superalloys, dissolving alloying elements to create a homogenous solid solution before quenching. Both processes tailor microstructures for improved strength and corrosion resistance according to the alloy system's chemical composition.

Step-by-Step Processes: Age Hardening vs Solution Treating

Age hardening involves heating the alloy to a specific temperature to dissolve the solute atoms, followed by rapid quenching to retain a supersaturated solid solution, and then reheating at a lower temperature to precipitate fine particles that strengthen the material. Solution treating requires heating the alloy to a high temperature where the alloying elements are fully dissolved, holding it there to achieve a homogeneous single-phase structure, and then quenching rapidly to lock in the solute atoms. Both processes optimize mechanical properties, with age hardening enhancing strength through controlled precipitation, while solution treating focuses on homogenization and preparation for subsequent precipitation.

Influence on Microstructure: Age Hardening vs Solution Treatment

Age hardening refines the microstructure by precipitating fine, uniformly distributed particles that hinder dislocation movement, enhancing strength and hardness in alloys like aluminum and titanium. Solution treatment dissolves alloying elements into a solid solution, creating a homogeneous microstructure and eliminating coarse precipitates, which improves ductility and prepares the alloy for subsequent age hardening. The interplay between solution treatment and age hardening determines final mechanical properties by controlling the size, distribution, and morphology of precipitates within the alloy matrix.

Industrial Applications: Choosing the Right Heat Treatment

Age hardening enhances alloy strength by precipitating fine particles within the metal matrix, making it ideal for aerospace and automotive components requiring high strength and durability. Solution treating dissolves alloying elements into a solid solution, providing uniform hardness and corrosion resistance crucial for marine and chemical industry parts. Selecting the appropriate heat treatment depends on the desired balance between mechanical properties and environmental performance specific to the industrial application.

Cost and Efficiency Considerations in Alloy Heat Treatments

Age hardening offers cost-effective and energy-efficient processing by enabling lower temperature treatments and shorter cycle times compared to solution treating. Solution treating requires higher temperatures and longer durations, increasing energy consumption and operational costs, but it produces a more uniform microstructure essential for certain high-performance alloys. Selecting between these methods depends on balancing production expenses with desired material properties and performance levels.

Age hardening vs Solution treating Infographic

materialdif.com

materialdif.com