Duplex alloys offer a unique combination of high strength and superior corrosion resistance due to their mixed microstructure of ferrite and austenite, making them ideal for harsh environments. Austenitic alloys, characterized by their face-centered cubic crystal structure, provide excellent toughness and resistance to oxidation but generally have lower strength compared to duplex alloys. The choice between duplex and austenitic alloys depends on the specific application requirements, balancing strength, corrosion resistance, and cost efficiency.

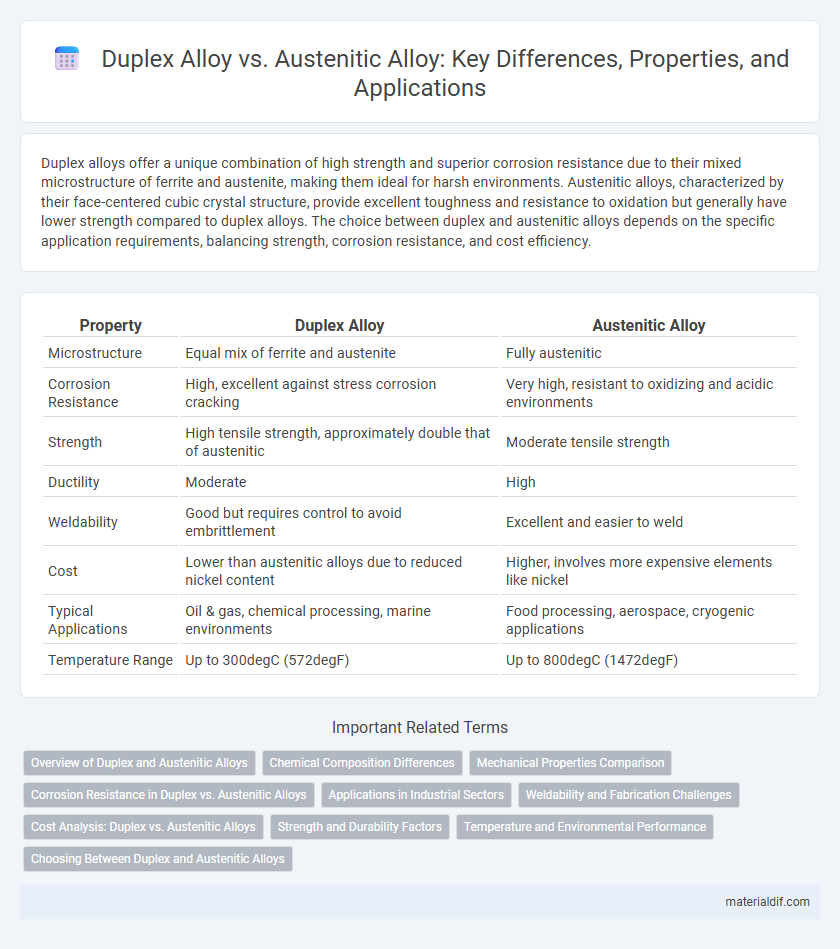

Table of Comparison

| Property | Duplex Alloy | Austenitic Alloy |

|---|---|---|

| Microstructure | Equal mix of ferrite and austenite | Fully austenitic |

| Corrosion Resistance | High, excellent against stress corrosion cracking | Very high, resistant to oxidizing and acidic environments |

| Strength | High tensile strength, approximately double that of austenitic | Moderate tensile strength |

| Ductility | Moderate | High |

| Weldability | Good but requires control to avoid embrittlement | Excellent and easier to weld |

| Cost | Lower than austenitic alloys due to reduced nickel content | Higher, involves more expensive elements like nickel |

| Typical Applications | Oil & gas, chemical processing, marine environments | Food processing, aerospace, cryogenic applications |

| Temperature Range | Up to 300degC (572degF) | Up to 800degC (1472degF) |

Overview of Duplex and Austenitic Alloys

Duplex alloys combine austenitic and ferritic microstructures, offering enhanced strength, corrosion resistance, and stress corrosion cracking resistance compared to traditional austenitic alloys. Austenitic alloys are primarily composed of high chromium and nickel content, providing excellent toughness, formability, and resistance to oxidation and corrosion in various environments. The balanced microstructure in duplex alloys results in superior mechanical properties and improved performance in aggressive chemical and chloride-rich environments.

Chemical Composition Differences

Duplex alloys typically contain balanced amounts of ferrite and austenite phases with higher chromium (19-28%) and moderate nickel (4-8%) content, providing enhanced corrosion resistance and strength. Austenitic alloys have higher nickel content (8-20%) and lower chromium (16-26%), emphasizing superior ductility and toughness but with reduced chloride stress corrosion resistance. The chemical composition differences directly influence microstructure, mechanical properties, and corrosion behavior in industrial applications.

Mechanical Properties Comparison

Duplex alloys exhibit superior mechanical properties compared to austenitic alloys, offering higher tensile strength ranging from 70 ksi to 100 ksi versus 50 ksi to 80 ksi for austenitic grades. Duplex alloys also demonstrate enhanced yield strength often exceeding 50 ksi, significantly outperforming the typical 30 ksi observed in austenitic alloys. The increased strength and improved resistance to stress corrosion cracking make duplex alloys ideal for demanding industrial applications requiring robust mechanical performance.

Corrosion Resistance in Duplex vs. Austenitic Alloys

Duplex alloys exhibit superior corrosion resistance compared to austenitic alloys due to their balanced microstructure of ferrite and austenite, which enhances resistance to stress corrosion cracking and chloride-induced pitting. The higher chromium and molybdenum content in duplex alloys significantly improves their performance in aggressive environments, such as seawater and chemical processing applications. Austenitic alloys, while corrosion-resistant, generally show lower resistance to localized corrosion and stress corrosion cracking under similar conditions.

Applications in Industrial Sectors

Duplex alloys are extensively used in chemical processing and oil and gas industries due to their superior corrosion resistance and high strength, making them ideal for harsh environments involving chloride exposure and high pressure. Austenitic alloys excel in food processing, pharmaceuticals, and cryogenic applications where excellent corrosion resistance, formability, and toughness at low temperatures are critical. Both alloys find significant use in marine engineering, but duplex alloys provide enhanced durability against stress corrosion cracking compared to austenitic types.

Weldability and Fabrication Challenges

Duplex alloys offer superior weldability compared to austenitic alloys due to their balanced microstructure of ferrite and austenite, which reduces the risk of hot cracking and improves corrosion resistance in welded joints. Austenitic alloys, while generally easier to form and fabricate, pose challenges in welding such as high thermal expansion and susceptibility to sensitization, leading to potential stress corrosion cracking. The fabrication of duplex alloys requires precise control of heat input and cooling rates to maintain phase balance, whereas austenitic alloys allow more flexibility but may require post-weld heat treatment to mitigate metallurgical issues.

Cost Analysis: Duplex vs. Austenitic Alloys

Duplex alloys offer a cost advantage over austenitic alloys due to their higher strength, which allows for thinner and lighter designs, reducing material usage and fabrication expenses. Maintenance costs are also lower for duplex alloys because of their superior corrosion resistance, especially in chloride-rich environments, leading to extended service life and fewer repairs. Despite a higher initial price per unit weight, the overall lifecycle cost of duplex alloys tends to be more economical compared to austenitic alternatives.

Strength and Durability Factors

Duplex alloys exhibit higher strength and enhanced corrosion resistance compared to austenitic alloys due to their mixed microstructure of ferrite and austenite phases, which provides superior mechanical properties and improved stress corrosion cracking resistance. Austenitic alloys, while offering excellent toughness and formability, generally have lower yield strength and are more prone to sensitization and intergranular corrosion under high temperature conditions. The dual-phase nature of duplex alloys results in greater durability in aggressive environments, making them ideal for applications demanding robust performance under mechanical stress and corrosive exposure.

Temperature and Environmental Performance

Duplex alloys exhibit superior temperature resistance compared to austenitic alloys, maintaining strength and corrosion resistance up to approximately 650degC, while austenitic alloys typically withstand temperatures around 500degC. The dual-phase microstructure of duplex alloys enhances their resistance to stress corrosion cracking and chloride-induced pitting in aggressive environments, outperforming austenitic alloys in marine and chemical processing applications. Austenitic alloys remain preferred in high-temperature oxidizing environments due to their excellent creep resistance and formability.

Choosing Between Duplex and Austenitic Alloys

When choosing between duplex and austenitic alloys, consider the superior strength and corrosion resistance of duplex alloys in chloride-rich environments, making them ideal for chemical processing and marine applications. Austenitic alloys offer excellent formability and high-temperature resistance, suitable for food processing and heat exchangers. Evaluate factors such as cost, mechanical properties, and specific operating conditions to select the optimal alloy for industrial performance and longevity.

Duplex alloy vs Austenitic alloy Infographic

materialdif.com

materialdif.com