White metal and Babbitt metal are both used as bearing materials but differ in composition and properties. White metal typically contains tin, lead, or antimony, providing excellent load-carrying capacity and wear resistance. Babbitt metal is a specific type of white metal alloy known for its soft, conformable surface, which reduces friction and accommodates slight misalignments in machinery.

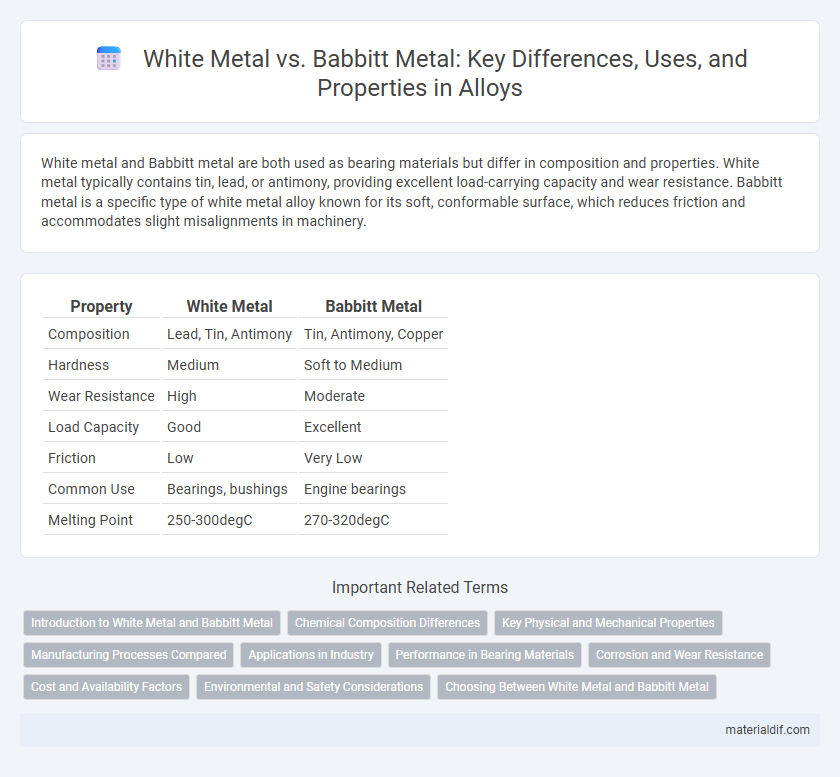

Table of Comparison

| Property | White Metal | Babbitt Metal |

|---|---|---|

| Composition | Lead, Tin, Antimony | Tin, Antimony, Copper |

| Hardness | Medium | Soft to Medium |

| Wear Resistance | High | Moderate |

| Load Capacity | Good | Excellent |

| Friction | Low | Very Low |

| Common Use | Bearings, bushings | Engine bearings |

| Melting Point | 250-300degC | 270-320degC |

Introduction to White Metal and Babbitt Metal

White metal, known for its low melting point and excellent anti-friction properties, is commonly used as a bearing alloy in heavy machinery. Babbitt metal, a specific type of white metal, typically consists of tin, antimony, and copper, engineered to reduce wear and extend the life of rotating components. Both alloys provide critical lubrication support in engines and industrial equipment, preventing metal-to-metal contact and ensuring smooth operation.

Chemical Composition Differences

White metal typically consists of tin, copper, and antimony, creating a hard and wear-resistant alloy ideal for bearing applications. Babbitt metal contains a higher percentage of tin or lead combined with antimony and copper, designed to provide excellent conformability and embedability for machinery parts. The chemical composition differences influence their mechanical properties, with white metal offering superior strength and Babbitt metal excelling in reducing friction and preventing seizure.

Key Physical and Mechanical Properties

White metal and babbitt metal are alloys commonly used as bearing materials, each distinguished by their physical and mechanical properties. White metal, typically composed of tin, antimony, and copper, offers high hardness and excellent wear resistance, making it suitable for heavy-load applications. Babbitt metal, characterized by its softer tin or lead base with antimony and copper, provides superior conformability and embeddability, enabling it to accommodate debris and misalignment in bearing surfaces.

Manufacturing Processes Compared

White metal and babbitt metal differ primarily in their manufacturing processes; white metal is typically cast or machined from alloys containing tin, lead, copper, and antimony, ensuring high hardness and wear resistance. Babbitt metal undergoes a precise casting process, where molten alloy primarily composed of tin, antimony, and copper is poured into bearing shells and then cooled to create a soft, conformable lining that accommodates shaft irregularities. The distinction between these processes results in white metal's suitability for heavy-duty applications, while babbitt metal excels in providing low-friction, self-lubricating surfaces in bearing assemblies.

Applications in Industry

White metal alloys, characterized by their high tin, lead, and antimony content, are widely used in heavy-duty bearing applications due to their excellent load-carrying capacity and fatigue resistance. Babbitt metal, a specific type of white metal alloy, is favored in industrial machinery for its superior conformability and embeddability, making it ideal for low-speed, high-load bearings in engines, turbines, and automotive components. Both alloys offer critical solutions in reducing friction and wear, extending the service life of rotating parts in manufacturing and power generation industries.

Performance in Bearing Materials

White metal and babbitt metal both serve as common bearing materials, but babbitt metal generally offers superior embeddability and conformability, reducing wear and extending bearing life. White metal, typically composed of tin or lead-based alloys, excels in load-carrying capacity and fatigue resistance, making it suitable for heavy-duty applications. Performance differences in bearing materials hinge on the specific alloy composition, with babbitt metals providing enhanced lubrication retention and white metals delivering higher durability under extreme pressures.

Corrosion and Wear Resistance

White metal exhibits superior corrosion resistance due to its higher tin and copper content, which forms a protective oxide layer preventing degradation in harsh environments. Babbitt metal, primarily composed of tin or lead alloys with antimony and copper, offers excellent wear resistance through its soft matrix that embeds abrasive particles, reducing friction and surface damage. In applications requiring both corrosion and wear resistance, white metal is preferred where chemical exposure is significant, while Babbitt metal excels in bearing surfaces subject to mechanical wear.

Cost and Availability Factors

White metal alloys often exhibit lower cost due to their simpler composition and widespread availability of base metals like tin and lead, making them a budget-friendly choice for industrial applications. Babbitt metal, containing precious metals such as antimony, copper, and tin in precise ratios, generally commands a higher price and can face supply constraints depending on market demand for these elements. Availability of babbitt metal is influenced by fluctuations in raw material sources, while white metal remains more consistently accessible for bearing and lining purposes.

Environmental and Safety Considerations

White metal alloys, known for their lead or tin base, present environmental concerns due to potential heavy metal toxicity and challenges in disposal or recycling. Babbitt metal, typically composed of tin, antimony, and copper, offers a safer alternative with reduced toxicity and better recyclability, aligning with stringent environmental regulations. Workplace safety improves when using Babbitt metal because it emits fewer harmful fumes during melting and casting processes compared to lead-containing white metals.

Choosing Between White Metal and Babbitt Metal

Choosing between white metal and babbitt metal depends on factors such as load capacity, operating temperature, and lubrication conditions. White metal alloys, primarily containing tin, lead, and antimony, offer excellent conformability and embedability, making them suitable for heavy-duty industrial bearings. Babbitt metal, composed mainly of tin, copper, and antimony, provides superior fatigue resistance and durability, ideal for high-speed applications requiring reliable performance.

White Metal vs Babbitt Metal Infographic

materialdif.com

materialdif.com