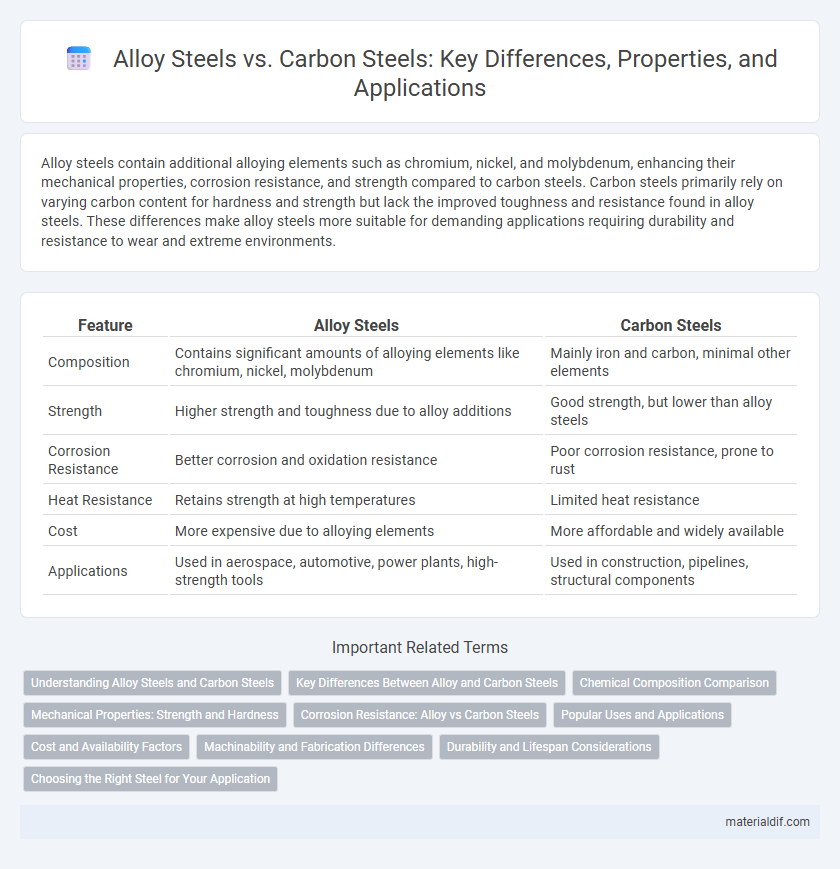

Alloy steels contain additional alloying elements such as chromium, nickel, and molybdenum, enhancing their mechanical properties, corrosion resistance, and strength compared to carbon steels. Carbon steels primarily rely on varying carbon content for hardness and strength but lack the improved toughness and resistance found in alloy steels. These differences make alloy steels more suitable for demanding applications requiring durability and resistance to wear and extreme environments.

Table of Comparison

| Feature | Alloy Steels | Carbon Steels |

|---|---|---|

| Composition | Contains significant amounts of alloying elements like chromium, nickel, molybdenum | Mainly iron and carbon, minimal other elements |

| Strength | Higher strength and toughness due to alloy additions | Good strength, but lower than alloy steels |

| Corrosion Resistance | Better corrosion and oxidation resistance | Poor corrosion resistance, prone to rust |

| Heat Resistance | Retains strength at high temperatures | Limited heat resistance |

| Cost | More expensive due to alloying elements | More affordable and widely available |

| Applications | Used in aerospace, automotive, power plants, high-strength tools | Used in construction, pipelines, structural components |

Understanding Alloy Steels and Carbon Steels

Alloy steels contain additional elements such as chromium, nickel, and molybdenum, which enhance properties like strength, hardness, and corrosion resistance compared to carbon steels. Carbon steels primarily consist of iron and carbon, offering good tensile strength and machinability but lower resistance to wear and corrosion. Understanding the composition differences is crucial for selecting materials tailored to specific engineering and industrial applications.

Key Differences Between Alloy and Carbon Steels

Alloy steels contain additional elements such as chromium, nickel, and molybdenum, which enhance properties like strength, corrosion resistance, and hardness compared to carbon steels that primarily consist of iron and carbon. Carbon steels are typically classified by their carbon content, influencing their ductility and tensile strength, whereas alloy steels offer more controlled mechanical and chemical properties due to the varied alloying elements. The key differences lie in their composition, mechanical performance, and suitability for specific applications, with alloy steels preferred for high-stress environments and carbon steels commonly used in construction and manufacturing.

Chemical Composition Comparison

Alloy steels contain significant amounts of alloying elements such as chromium, nickel, molybdenum, and vanadium, which enhance properties like strength, toughness, and corrosion resistance compared to carbon steels. Carbon steels primarily consist of iron and carbon, with carbon content typically ranging from 0.02% to 2.1%, and have limited alloying elements, resulting in lower mechanical performance and corrosion resistance. The presence of additional alloying elements in alloy steels alters their microstructure and improves hardenability, making them suitable for demanding industrial applications.

Mechanical Properties: Strength and Hardness

Alloy steels exhibit higher strength and hardness compared to carbon steels due to the presence of alloying elements such as chromium, nickel, and molybdenum, which enhance their mechanical properties by refining the microstructure and promoting hardenability. Carbon steels primarily rely on carbon content for strength and hardness, but excessive carbon can reduce ductility and toughness, limiting their mechanical performance. The superior mechanical properties of alloy steels make them suitable for demanding applications requiring enhanced wear resistance and high strength under stress.

Corrosion Resistance: Alloy vs Carbon Steels

Alloy steels exhibit superior corrosion resistance compared to carbon steels due to the presence of elements such as chromium, nickel, and molybdenum, which form a protective oxide layer on the surface. Carbon steels lack these alloying elements and are more prone to rust and degradation when exposed to moisture and chemicals. This enhanced corrosion resistance makes alloy steels ideal for use in harsh environments, including marine, chemical processing, and high-temperature applications.

Popular Uses and Applications

Alloy steels are widely used in aerospace, automotive, and tool manufacturing due to their enhanced strength, toughness, and resistance to wear and corrosion, making them ideal for high-performance parts like gears, shafts, and aircraft components. Carbon steels, commonly found in construction, pipelines, and automotive bodies, offer cost-effective solutions with good weldability and machinability, suited for structural beams, pipes, and everyday machinery. The choice between alloy and carbon steel depends on specific mechanical property requirements and environmental conditions of the application.

Cost and Availability Factors

Alloy steels typically cost more than carbon steels due to the addition of elements like chromium, nickel, and molybdenum that enhance performance but increase production expenses. Carbon steels are more widely available and economical, making them a preferred choice for general construction and manufacturing applications. The availability of alloy steels can be limited in smaller markets, affecting lead times and overall project budgets.

Machinability and Fabrication Differences

Alloy steels exhibit enhanced machinability compared to carbon steels due to the presence of alloying elements like chromium, nickel, and molybdenum that improve hardness and wear resistance. Carbon steels, being simpler in composition, offer easier fabrication with standard machining tools but may require more frequent tool maintenance due to their lower hardness. The choice between alloy and carbon steels depends on the balance between machinability and the desired mechanical properties for specific industrial applications.

Durability and Lifespan Considerations

Alloy steels typically offer superior durability and longer lifespan compared to carbon steels due to the presence of alloying elements such as chromium, nickel, and molybdenum, which enhance corrosion resistance and toughness. Carbon steels, while generally more affordable, tend to have lower wear resistance and are more susceptible to rust and fatigue over time. Therefore, alloy steels are preferred in applications demanding high strength and prolonged durability under harsh conditions.

Choosing the Right Steel for Your Application

Alloy steels contain additional elements such as chromium, nickel, and molybdenum, which enhance properties like strength, toughness, and corrosion resistance, making them ideal for high-performance applications. Carbon steels primarily consist of iron and carbon, offering cost-effective solutions with good wear resistance and strength suitable for general construction and manufacturing. Selecting the right steel depends on application requirements, balancing factors like mechanical properties, environmental exposure, and budget constraints to ensure optimal performance and durability.

Alloy Steels vs Carbon Steels Infographic

materialdif.com

materialdif.com