Cupronickel and nickel silver are both durable metal alloys used in various applications, but their compositions and properties differ significantly. Cupronickel primarily consists of copper and nickel, offering excellent corrosion resistance and antimicrobial properties, making it ideal for marine and coinage uses. Nickel silver, containing copper, nickel, and zinc, has a silvery appearance without any actual silver content and is favored for decorative items and musical instruments due to its lustrous finish and ease of fabrication.

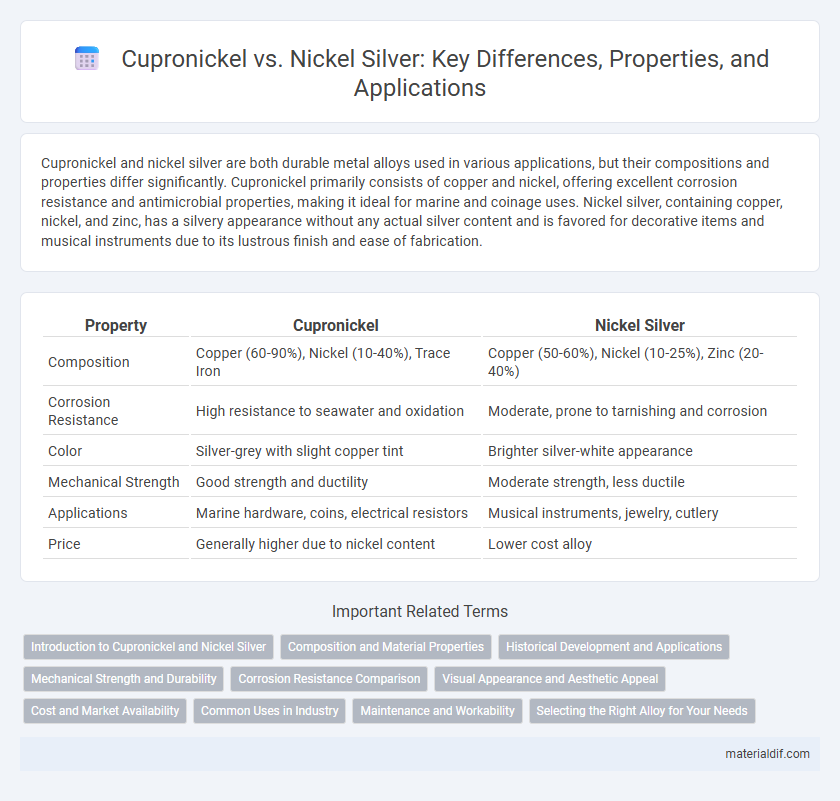

Table of Comparison

| Property | Cupronickel | Nickel Silver |

|---|---|---|

| Composition | Copper (60-90%), Nickel (10-40%), Trace Iron | Copper (50-60%), Nickel (10-25%), Zinc (20-40%) |

| Corrosion Resistance | High resistance to seawater and oxidation | Moderate, prone to tarnishing and corrosion |

| Color | Silver-grey with slight copper tint | Brighter silver-white appearance |

| Mechanical Strength | Good strength and ductility | Moderate strength, less ductile |

| Applications | Marine hardware, coins, electrical resistors | Musical instruments, jewelry, cutlery |

| Price | Generally higher due to nickel content | Lower cost alloy |

Introduction to Cupronickel and Nickel Silver

Cupronickel is a corrosion-resistant alloy primarily composed of copper and nickel, commonly used in marine engineering and coinage due to its excellent resistance to seawater. Nickel silver, also known as German silver, is an alloy of copper, nickel, and zinc, valued for its silvery appearance and used extensively in musical instruments and decorative items. Both alloys share nickel content but differ significantly in corrosion resistance and applications.

Composition and Material Properties

Cupronickel consists predominantly of copper (typically 60-90%) combined with nickel and small amounts of iron and manganese, resulting in excellent corrosion resistance and high thermal conductivity. Nickel silver, an alloy of copper, nickel, and zinc, contains more zinc (typically 10-30%) but no actual silver, offering greater strength and a brighter, more silvery appearance. The higher copper content in cupronickel provides superior resistance to seawater corrosion, while nickel silver's increased zinc improves hardness and machinability.

Historical Development and Applications

Cupronickel, an alloy primarily composed of copper and nickel, has been historically valued for its excellent corrosion resistance and antimicrobial properties, making it a staple in marine and coinage applications since the 19th century. Nickel silver, also known as German silver, contains copper, nickel, and zinc and gained prominence in the 19th century for its aesthetic resemblance to silver, leading to widespread use in decorative items, musical instruments, and cutlery. Both alloys have evolved with technological advancements, but cupronickel remains preferred for durability in harsh environments, while nickel silver dominates artistic and household products due to its lustrous finish.

Mechanical Strength and Durability

Cupronickel exhibits superior mechanical strength and corrosion resistance compared to nickel silver, making it more durable in marine and industrial environments. The high copper and nickel content in cupronickel alloys enhances tensile strength and fatigue resistance, while nickel silver, containing higher zinc levels, is more prone to stress corrosion and wear. These properties make cupronickel the preferred choice for demanding applications such as heat exchangers and seawater piping systems.

Corrosion Resistance Comparison

Cupronickel exhibits superior corrosion resistance compared to nickel silver, particularly in marine environments due to its high copper and nickel content combined with small amounts of iron and manganese, which enhance durability against saltwater corrosion. Nickel silver, while aesthetically similar, contains zinc that decreases its resistance to oxidation and pitting, making it less suitable for harsh or saline conditions. The electrochemical stability of cupronickel alloys makes them the preferred choice for applications requiring long-term exposure to corrosive environments, such as seawater piping and coinage.

Visual Appearance and Aesthetic Appeal

Cupronickel features a distinctive pinkish hue due to its copper content, offering a warm, rich aesthetic compared to the pale, silvery tone of nickel silver, which resembles sterling silver but contains no actual silver. The natural luster and corrosion resistance of cupronickel make it ideal for marine and decorative applications demanding long-lasting shine and color stability. Nickel silver's brighter, more reflective finish suits ornamental uses where a sleek, polished appearance is desired without the higher cost of precious metals.

Cost and Market Availability

Cupronickel typically costs more than nickel silver due to its higher copper and nickel content, which are more expensive raw materials. Market availability of cupronickel is strong in marine and electrical applications because of its corrosion resistance and thermal conductivity, whereas nickel silver is widely available and often preferred in decorative and musical instrument manufacturing for its lower cost and ease of fabrication. The balance between cost and specific application requirements largely dictates the choice between these two alloys in industry.

Common Uses in Industry

Cupronickel alloys are widely used in marine engineering, coinage, and desalination plants due to their excellent corrosion resistance and anti-fouling properties. Nickel silver, an alloy of copper, nickel, and zinc, is commonly employed in musical instruments, jewelry, and decorative hardware because of its bright, silver-like appearance and good mechanical strength. Both alloys find applications in electrical connectors and heat exchangers where durability and conductivity are essential.

Maintenance and Workability

Cupronickel offers superior corrosion resistance and requires less maintenance than nickel silver, making it ideal for marine and industrial applications exposed to harsh environments. Nickel silver, although easier to machine due to its softer composition, demands more frequent polishing to prevent tarnish and maintain its aesthetic appeal. Workability differences influence tool wear; cupronickel's harder nature increases machining costs, whereas nickel silver allows quicker fabrication with less tool degradation.

Selecting the Right Alloy for Your Needs

Cupronickel, composed primarily of copper and nickel, offers superior corrosion resistance and excellent thermal conductivity, making it ideal for marine and heat exchanger applications. Nickel silver, an alloy of copper, nickel, and zinc, provides a brighter appearance and enhanced machinability, favored in decorative and musical instrument manufacturing. Selecting the right alloy depends on specific needs such as environmental exposure, mechanical strength, and aesthetic requirements.

Cupronickel vs Nickel Silver Infographic

materialdif.com

materialdif.com