Ferritic alloys are primarily composed of iron and chromium, offering excellent resistance to stress corrosion cracking and magnetic properties, making them suitable for automotive and industrial applications. Austenitic alloys, containing higher levels of nickel and chromium, provide superior corrosion resistance, toughness, and non-magnetic characteristics, commonly used in chemical processing and food industries. The key difference lies in their crystal structure, influencing mechanical properties and corrosion resistance in various environments.

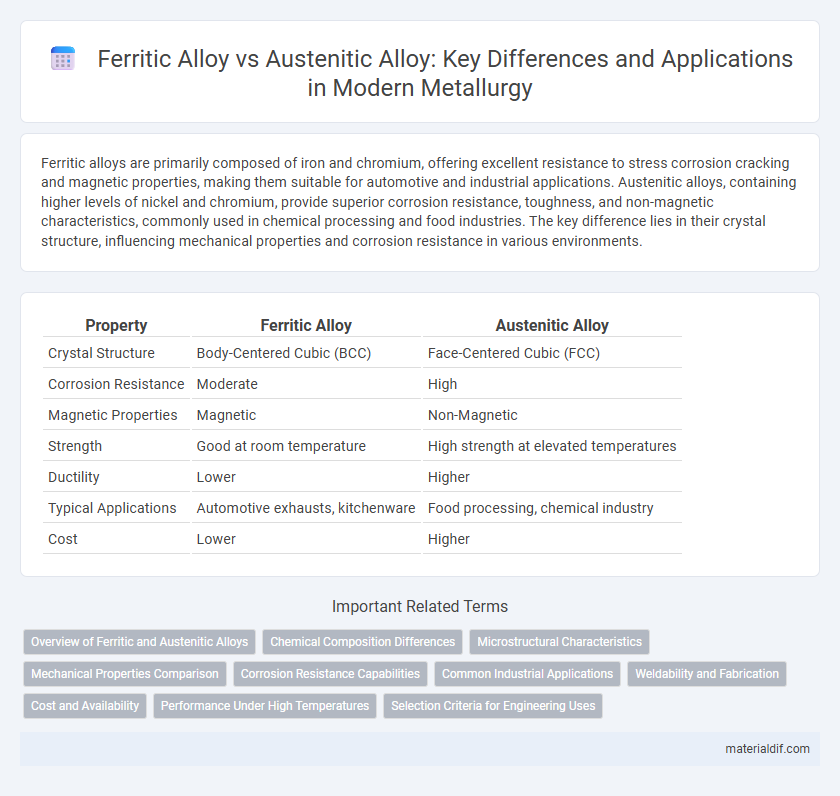

Table of Comparison

| Property | Ferritic Alloy | Austenitic Alloy |

|---|---|---|

| Crystal Structure | Body-Centered Cubic (BCC) | Face-Centered Cubic (FCC) |

| Corrosion Resistance | Moderate | High |

| Magnetic Properties | Magnetic | Non-Magnetic |

| Strength | Good at room temperature | High strength at elevated temperatures |

| Ductility | Lower | Higher |

| Typical Applications | Automotive exhausts, kitchenware | Food processing, chemical industry |

| Cost | Lower | Higher |

Overview of Ferritic and Austenitic Alloys

Ferritic alloys primarily consist of iron and have a body-centered cubic (BCC) crystal structure, offering high resistance to corrosion and good mechanical properties at elevated temperatures. Austenitic alloys, characterized by their face-centered cubic (FCC) structure due to higher nickel content, exhibit superior toughness and excellent corrosion resistance, especially in highly corrosive environments. The selection between ferritic and austenitic alloys is influenced by factors such as thermal conductivity, magnetic properties, and weldability required in specific industrial applications.

Chemical Composition Differences

Ferritic alloys primarily consist of iron with a high chromium content typically ranging from 10.5% to 30%, and very low carbon levels below 0.1%, which enhances corrosion resistance and magnetic properties. Austenitic alloys contain higher amounts of nickel, usually 8% to 20%, along with chromium levels around 18%, providing excellent ductility, toughness, and resistance to oxidation. The distinct chemical compositions influence their crystal structures, with ferritic alloys having a body-centered cubic (BCC) structure and austenitic alloys exhibiting a face-centered cubic (FCC) structure.

Microstructural Characteristics

Ferritic alloys exhibit a body-centered cubic (BCC) microstructure characterized by magnetic properties and good resistance to stress corrosion cracking. Austenitic alloys possess a face-centered cubic (FCC) microstructure, which provides superior toughness, ductility, and enhanced corrosion resistance in aggressive environments. The stability of ferrite phases at higher temperatures contrasts with the austenite phases' ability to maintain mechanical strength and corrosion resistance at cryogenic temperatures.

Mechanical Properties Comparison

Ferritic alloys exhibit higher tensile strength and improved resistance to stress corrosion cracking compared to austenitic alloys, making them suitable for high-stress environments. Austenitic alloys demonstrate superior ductility and toughness, maintaining excellent mechanical performance at cryogenic temperatures. The lower thermal expansion and better magnetic properties of ferritic alloys contrast with the enhanced corrosion resistance and weldability characteristic of austenitic alloys.

Corrosion Resistance Capabilities

Ferritic alloys demonstrate superior corrosion resistance in oxidizing environments due to higher chromium content and stable ferrite phase, which enhances resistance to stress corrosion cracking. Austenitic alloys offer better overall corrosion resistance in acidic and chloride-rich environments, attributed to their face-centered cubic structure and higher nickel content that improves pitting and crevice corrosion resistance. Both alloy types are selected based on specific environmental exposure and mechanical requirements to optimize longevity and performance in corrosive conditions.

Common Industrial Applications

Ferritic alloys are commonly used in automotive exhaust systems, industrial gas turbines, and heat exchangers due to their excellent corrosion resistance and magnetic properties. Austenitic alloys are preferred in chemical processing equipment, food processing plants, and cryogenic applications because of their superior corrosion resistance, high ductility, and non-magnetic nature. Both alloys are essential in stainless steel manufacturing, with ferritic alloys favored for cost-effective applications and austenitic alloys chosen for high-performance environments.

Weldability and Fabrication

Ferritic alloys exhibit superior weldability due to their lower thermal expansion and reduced susceptibility to hot cracking, making them ideal for fabrication in high-temperature applications. Austenitic alloys, while offering excellent corrosion resistance and toughness, require precise control during welding to prevent sensitization and intergranular corrosion. Fabrication of austenitic alloys often involves slower cooling rates and post-weld heat treatment to maintain structural integrity and performance.

Cost and Availability

Ferritic alloys typically offer lower cost and greater availability due to their simpler iron-chromium composition and widespread production. Austenitic alloys, containing higher nickel content, are more expensive and less abundant, reflecting reliance on costly raw materials. The economic advantage of ferritic alloys makes them preferable for large-scale applications where budget constraints and material sourcing are critical.

Performance Under High Temperatures

Ferritic alloys exhibit superior resistance to stress corrosion cracking and maintain structural stability under high-temperature conditions up to approximately 600degC, making them ideal for applications requiring thermal fatigue resistance. Austenitic alloys, with their face-centered cubic crystal structure, provide excellent creep strength and corrosion resistance at elevated temperatures, typically performing well above 700degC and in oxidizing environments. The choice between ferritic and austenitic alloys depends on the specific thermal exposure, mechanical load, and environmental factors in high-temperature industrial applications.

Selection Criteria for Engineering Uses

Ferritic alloys excel in magnetic properties and corrosion resistance at high temperatures, making them ideal for automotive exhaust systems and industrial furnace components. Austenitic alloys offer superior strength, ductility, and resistance to oxidation and various corrosive environments, favoring applications in chemical processing and cryogenic equipment. Selection between ferritic and austenitic alloys depends on specific factors such as operating temperature range, mechanical stress requirements, and exposure to corrosive agents.

Ferritic Alloy vs Austenitic Alloy Infographic

materialdif.com

materialdif.com