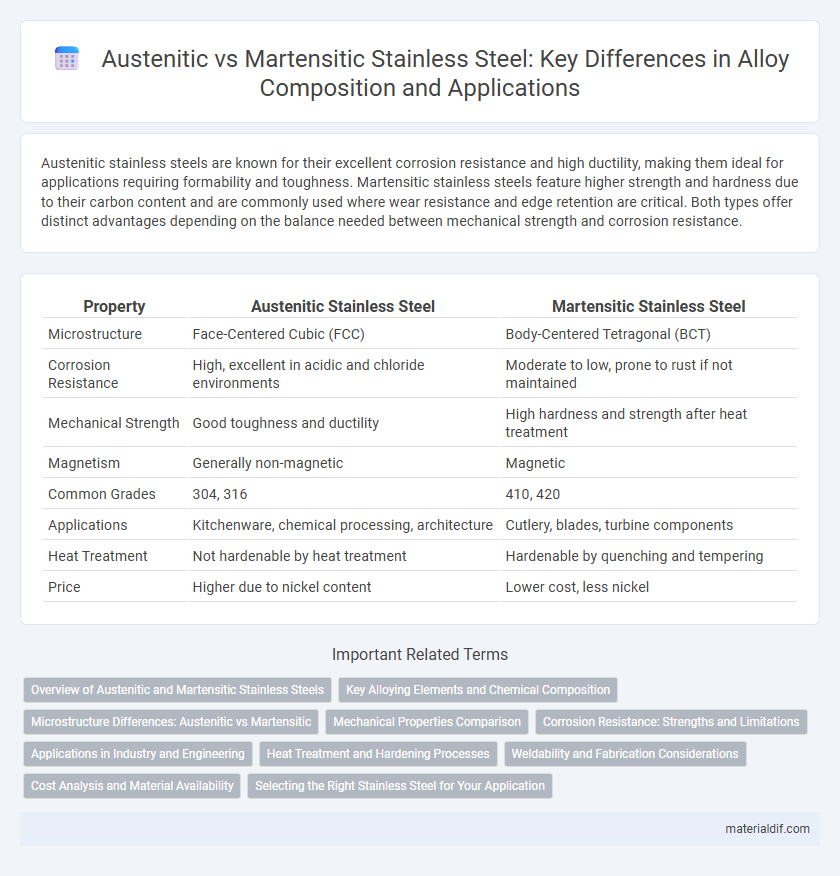

Austenitic stainless steels are known for their excellent corrosion resistance and high ductility, making them ideal for applications requiring formability and toughness. Martensitic stainless steels feature higher strength and hardness due to their carbon content and are commonly used where wear resistance and edge retention are critical. Both types offer distinct advantages depending on the balance needed between mechanical strength and corrosion resistance.

Table of Comparison

| Property | Austenitic Stainless Steel | Martensitic Stainless Steel |

|---|---|---|

| Microstructure | Face-Centered Cubic (FCC) | Body-Centered Tetragonal (BCT) |

| Corrosion Resistance | High, excellent in acidic and chloride environments | Moderate to low, prone to rust if not maintained |

| Mechanical Strength | Good toughness and ductility | High hardness and strength after heat treatment |

| Magnetism | Generally non-magnetic | Magnetic |

| Common Grades | 304, 316 | 410, 420 |

| Applications | Kitchenware, chemical processing, architecture | Cutlery, blades, turbine components |

| Heat Treatment | Not hardenable by heat treatment | Hardenable by quenching and tempering |

| Price | Higher due to nickel content | Lower cost, less nickel |

Overview of Austenitic and Martensitic Stainless Steels

Austenitic stainless steels, characterized by high chromium and nickel content, offer excellent corrosion resistance and superior toughness, making them ideal for chemical processing and food industry applications. Martensitic stainless steels contain higher carbon levels, providing enhanced hardness and strength but lower corrosion resistance, commonly used in cutlery, surgical instruments, and valve components. Both types differ significantly in microstructure, mechanical properties, and heat treatment responses, influencing their specific industrial applications.

Key Alloying Elements and Chemical Composition

Austenitic stainless steels primarily contain high levels of chromium (16-26%) and nickel (6-22%), which enhance corrosion resistance and stabilize the face-centered cubic (FCC) crystal structure. Martensitic stainless steels have lower chromium content (11-18%) and minimal nickel, with higher carbon levels (0.1-1.2%) to promote hardness and strength through the body-centered tetragonal (BCT) structure. The distinct chemical compositions directly influence their mechanical properties, corrosion resistance, and applications in various industrial environments.

Microstructure Differences: Austenitic vs Martensitic

Austenitic stainless steel features a face-centered cubic (FCC) microstructure, which provides superior ductility and corrosion resistance. Martensitic stainless steel exhibits a body-centered tetragonal (BCT) microstructure formed by rapid quenching, resulting in higher hardness and strength but reduced corrosion resistance. The distinct microstructural variations directly influence their mechanical properties and suitability for different industrial applications.

Mechanical Properties Comparison

Austenitic stainless steels exhibit superior toughness and excellent ductility, making them highly resistant to impact and deformation under stress, with tensile strengths typically ranging from 515 to 827 MPa. Martensitic stainless steels offer higher hardness and strength, often exceeding 1300 MPa after heat treatment, but with reduced ductility and toughness compared to austenitic grades. The choice between these alloys depends on balancing mechanical strength requirements against corrosion resistance and formability for specific industrial applications.

Corrosion Resistance: Strengths and Limitations

Austenitic stainless steels exhibit superior corrosion resistance due to their high chromium and nickel content, making them ideal for harsh, oxidizing environments like marine or chemical applications. Martensitic stainless steels offer moderate corrosion resistance but excel in strength and hardness, which limits their use in highly corrosive conditions compared to austenitic grades. The lower chromium content and heat treatment susceptibility of martensitic alloys make them prone to pitting and stress corrosion cracking in aggressive environments.

Applications in Industry and Engineering

Austenitic stainless steel is widely used in chemical processing equipment, food industry machinery, and architectural components due to its excellent corrosion resistance and high ductility. Martensitic stainless steel, favored for its high strength and wear resistance, is commonly applied in manufacturing cutting tools, surgical instruments, and turbine blades. Both alloys serve critical roles in engineering, with austenitic grades dominating environments requiring superior corrosion resistance and martensitic grades preferred where mechanical durability is paramount.

Heat Treatment and Hardening Processes

Austenitic stainless steels resist heat treatment hardening due to their face-centered cubic (FCC) crystal structure, relying primarily on work hardening for strength enhancement. Martensitic stainless steels undergo heat treatment processes such as quenching and tempering, which transform their body-centered tetragonal (BCT) structure to achieve significant hardness and improved mechanical properties. The martensitic phase formation during rapid cooling is essential for achieving maximum hardness, making heat treatment critical for their performance in high-wear applications.

Weldability and Fabrication Considerations

Austenitic stainless steels exhibit excellent weldability and superior corrosion resistance, making them ideal for complex fabrication processes that require extensive welding. Martensitic stainless steels, while offering high strength and hardness, present challenges during welding due to their tendency toward cracking and distortion from rapid cooling rates. Fabrication of martensitic alloys often requires precise control of heat treatment and post-weld thermal processes to maintain mechanical properties and prevent brittleness.

Cost Analysis and Material Availability

Austenitic stainless steel typically costs more due to higher nickel content but benefits from widespread availability and corrosion resistance, making it ideal for diverse applications. Martensitic stainless steel is generally less expensive with a higher carbon content, offering enhanced hardness and strength but limited corrosion resistance, thus availability can be more region-specific. Cost analysis favors martensitic grades for budget-conscious projects requiring wear resistance, while austenitic grades suit environments demanding superior durability and broad material sourcing.

Selecting the Right Stainless Steel for Your Application

Austenitic stainless steel offers excellent corrosion resistance and good formability, making it ideal for applications requiring durability in harsh environments and high-temperature conditions. Martensitic stainless steel provides superior hardness and strength, suitable for wear-resistant tools and components subjected to mechanical stress. Selecting the right stainless steel involves evaluating factors such as corrosion exposure, mechanical load, and thermal requirements to ensure optimal performance and longevity.

Austenitic stainless vs Martensitic stainless Infographic

materialdif.com

materialdif.com