Low alloy steel contains a smaller percentage of alloying elements, typically under 5%, resulting in enhanced strength and toughness while maintaining cost-effectiveness. High alloy steel, with a higher alloy content often exceeding 10%, offers superior corrosion resistance, hardness, and heat resistance, making it ideal for extreme environments. The choice between low and high alloy steel depends on the specific mechanical properties and environmental conditions required for the application.

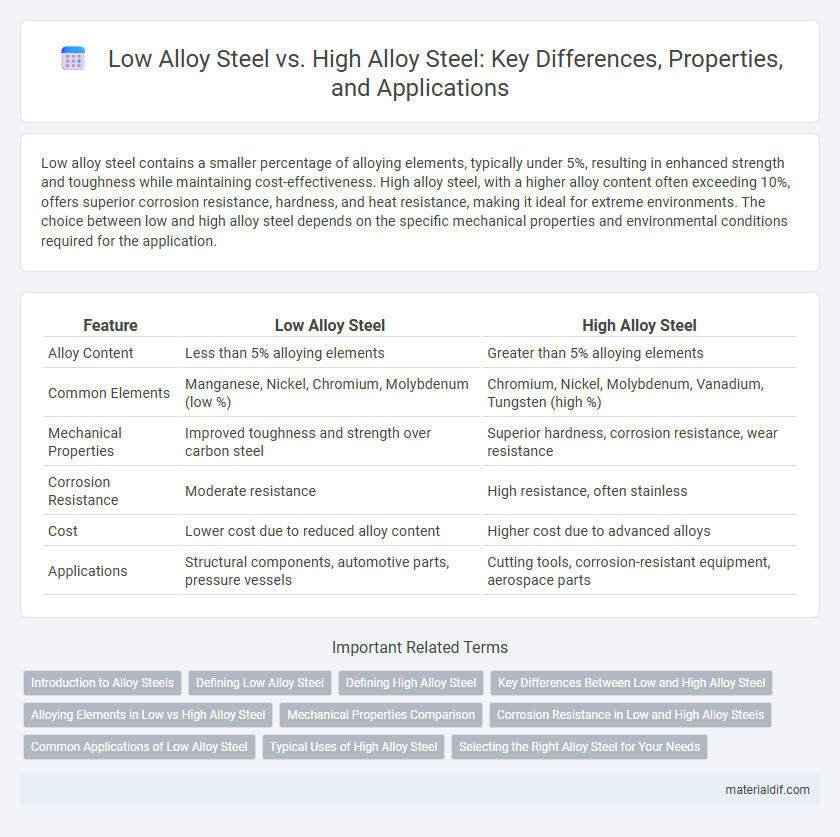

Table of Comparison

| Feature | Low Alloy Steel | High Alloy Steel |

|---|---|---|

| Alloy Content | Less than 5% alloying elements | Greater than 5% alloying elements |

| Common Elements | Manganese, Nickel, Chromium, Molybdenum (low %) | Chromium, Nickel, Molybdenum, Vanadium, Tungsten (high %) |

| Mechanical Properties | Improved toughness and strength over carbon steel | Superior hardness, corrosion resistance, wear resistance |

| Corrosion Resistance | Moderate resistance | High resistance, often stainless |

| Cost | Lower cost due to reduced alloy content | Higher cost due to advanced alloys |

| Applications | Structural components, automotive parts, pressure vessels | Cutting tools, corrosion-resistant equipment, aerospace parts |

Introduction to Alloy Steels

Low alloy steel contains a total alloying element content of up to 5%, primarily including elements such as manganese, nickel, chromium, and molybdenum to enhance strength, toughness, and corrosion resistance. High alloy steel features a higher alloy content, often exceeding 10%, with stainless steels being a common example characterized by high chromium and nickel levels providing superior corrosion resistance. Both low and high alloy steels are essential in industries requiring specific mechanical properties and environmental resistance, tailored through precise metallurgical compositions.

Defining Low Alloy Steel

Low alloy steel contains typically between 1% and 5% alloying elements such as chromium, nickel, and molybdenum, which enhance mechanical properties and corrosion resistance without significantly increasing cost. Its balanced composition offers improved strength, toughness, and wear resistance compared to carbon steel, making it ideal for structural and automotive applications. Unlike high alloy steel, low alloy steel maintains a lower alloy content to ensure weldability and cost-effectiveness while providing essential performance enhancements.

Defining High Alloy Steel

High alloy steel contains alloying elements exceeding 8% by weight, significantly enhancing its mechanical properties and corrosion resistance compared to low alloy steel, which typically contains less than 8% alloy content. Elements such as chromium, nickel, molybdenum, and vanadium are commonly added to high alloy steels to achieve specific characteristics like increased hardness, tensile strength, and resistance to oxidation and wear. These steels are often used in demanding environments, including aerospace, chemical processing, and high-performance tooling applications.

Key Differences Between Low and High Alloy Steel

Low alloy steel contains a total alloying element content of up to 5%, primarily including elements like manganese, nickel, and chromium for improved strength and toughness. High alloy steel exceeds 5% alloy content, often containing significant amounts of chromium, nickel, molybdenum, or vanadium, which provide enhanced corrosion resistance and hardness. Key differences lie in their mechanical properties, corrosion resistance, and typical applications, with low alloy steel used in structural components and automotive parts, while high alloy steel is favored for stainless steel tools and chemical processing equipment.

Alloying Elements in Low vs High Alloy Steel

Low alloy steel typically contains alloying elements such as manganese, nickel, chromium, and molybdenum in concentrations generally below 5%, which enhance strength, toughness, and corrosion resistance while maintaining weldability and cost efficiency. High alloy steel, including stainless steel, contains higher percentages of alloying elements like chromium (above 10.5%), nickel, and sometimes additional elements such as cobalt or vanadium, resulting in superior corrosion resistance, hardness, and thermal stability. The specific alloying element composition directly influences mechanical properties and industrial applications, differentiating low alloy steels used in structural and pressure vessel applications from high alloy steels designed for extreme environments and chemical resistance.

Mechanical Properties Comparison

Low alloy steel typically exhibits higher strength and improved toughness due to its controlled alloying elements, making it suitable for structural applications requiring wear resistance and moderate corrosion resistance. High alloy steel contains a greater percentage of alloying elements such as chromium, nickel, and molybdenum, resulting in superior hardness, tensile strength, and enhanced corrosion and heat resistance, ideal for extreme environments. The mechanical properties of high alloy steels generally surpass those of low alloy steels in terms of hardness and durability, but low alloy steels offer better weldability and ductility for fabrication processes.

Corrosion Resistance in Low and High Alloy Steels

Low alloy steel contains lower amounts of alloying elements, offering moderate corrosion resistance primarily through elements such as nickel and chromium. High alloy steel boasts significantly enhanced corrosion resistance due to higher concentrations of chromium, nickel, molybdenum, and sometimes copper, which form a robust passive layer protecting against oxidation and chemical attack. This increased alloy content in high alloy steels, exemplified by stainless steels, makes them ideal for harsh environments requiring superior durability and resistance to rust.

Common Applications of Low Alloy Steel

Low alloy steel is extensively used in construction, automotive manufacturing, and pipelines due to its enhanced mechanical properties and corrosion resistance compared to carbon steel. Common applications include structural beams, pressure vessels, and heavy machinery components, where a balance of strength and fabrication ease is crucial. Its affordability and weldability make it a preferred choice for infrastructure projects and transportation equipment.

Typical Uses of High Alloy Steel

High alloy steel is primarily used in environments requiring exceptional corrosion resistance, high strength, and durability, such as in aerospace components, chemical processing equipment, and surgical instruments. Its enhanced properties make it ideal for manufacturing turbine blades, marine hardware, and parts exposed to extreme temperatures and aggressive chemicals. In contrast to low alloy steel, high alloy steel offers superior performance in demanding industrial applications where longevity and reliability are critical.

Selecting the Right Alloy Steel for Your Needs

Low alloy steel contains a small percentage of alloying elements (typically less than 5%), offering improved strength and toughness while maintaining cost-effectiveness, ideal for structural and automotive applications. High alloy steel, with higher alloy content such as stainless steel, provides enhanced corrosion resistance, hardness, and wear properties, suited for harsh environments and specialized industries. Selecting the right alloy steel depends on balancing factors like mechanical properties, environmental conditions, and budget constraints to optimize performance and durability.

Low Alloy Steel vs High Alloy Steel Infographic

materialdif.com

materialdif.com