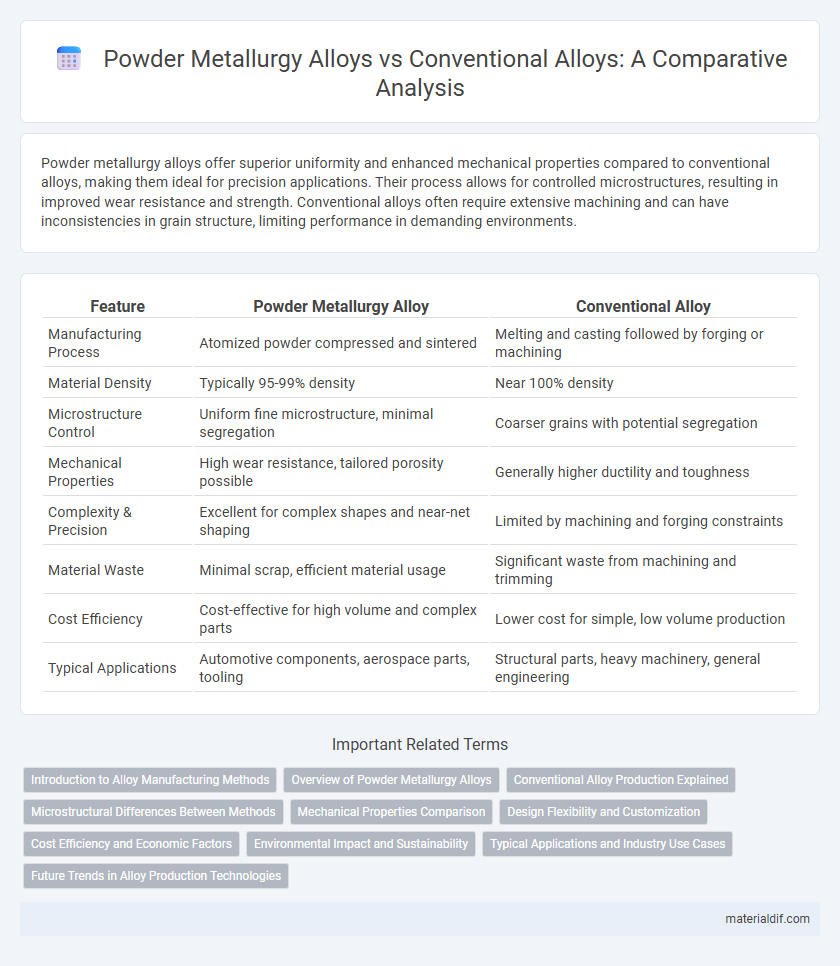

Powder metallurgy alloys offer superior uniformity and enhanced mechanical properties compared to conventional alloys, making them ideal for precision applications. Their process allows for controlled microstructures, resulting in improved wear resistance and strength. Conventional alloys often require extensive machining and can have inconsistencies in grain structure, limiting performance in demanding environments.

Table of Comparison

| Feature | Powder Metallurgy Alloy | Conventional Alloy |

|---|---|---|

| Manufacturing Process | Atomized powder compressed and sintered | Melting and casting followed by forging or machining |

| Material Density | Typically 95-99% density | Near 100% density |

| Microstructure Control | Uniform fine microstructure, minimal segregation | Coarser grains with potential segregation |

| Mechanical Properties | High wear resistance, tailored porosity possible | Generally higher ductility and toughness |

| Complexity & Precision | Excellent for complex shapes and near-net shaping | Limited by machining and forging constraints |

| Material Waste | Minimal scrap, efficient material usage | Significant waste from machining and trimming |

| Cost Efficiency | Cost-effective for high volume and complex parts | Lower cost for simple, low volume production |

| Typical Applications | Automotive components, aerospace parts, tooling | Structural parts, heavy machinery, general engineering |

Introduction to Alloy Manufacturing Methods

Powder metallurgy alloy manufacturing involves blending metal powders, compacting them under high pressure, and sintering at elevated temperatures to form a dense, uniform material with superior mechanical properties. Conventional alloy methods typically rely on melting and casting processes, which can introduce segregation and porosity, impacting material consistency and performance. Powder metallurgy offers enhanced control over alloy composition and microstructure, enabling the production of complex shapes with minimal waste compared to traditional casting techniques.

Overview of Powder Metallurgy Alloys

Powder metallurgy alloys are engineered by compacting metal powders followed by sintering, allowing precise control over composition and microstructure. These alloys exhibit superior uniformity, enhanced mechanical properties, and reduced material waste compared to conventional cast or wrought alloys. Applications span aerospace, automotive, and biomedical industries where high-performance, complex-shaped components are critical.

Conventional Alloy Production Explained

Conventional alloy production involves melting and casting metal elements into a homogeneous mixture, followed by shaping through processes such as forging, rolling, or extrusion. This method offers benefits like high structural integrity and predictable mechanical properties but often requires extensive machining and results in material waste. Compared to powder metallurgy, conventional alloy production typically has longer lead times and less control over microstructure refinement.

Microstructural Differences Between Methods

Powder metallurgy alloy demonstrates a finer and more uniform microstructure compared to conventional alloy due to controlled particle size and sintering processes. The absence of large grain boundaries and reduced porosity in powder metallurgy enhances mechanical properties and corrosion resistance. Conventional alloy typically shows coarser grains and segregation caused by solidification, leading to less homogeneous microstructures.

Mechanical Properties Comparison

Powder metallurgy alloys exhibit superior mechanical properties compared to conventional alloys, including enhanced tensile strength, improved hardness, and better wear resistance due to their fine and uniform microstructure. The controlled particle size distribution and homogeneous composition in powder metallurgy materials lead to increased fatigue strength and greater dimensional stability under high-stress conditions. Conventional alloys often suffer from segregation and porosity, which reduce overall mechanical performance and limit their application in high-precision engineering components.

Design Flexibility and Customization

Powder metallurgy alloys offer superior design flexibility and customization compared to conventional alloys due to their ability to create complex geometries and fine microstructures through precise powder blending and sintering processes. This method enables tailored alloy compositions and porosity control, which enhances performance characteristics such as strength, wear resistance, and thermal conductivity. In contrast, conventional alloys often face limitations in design due to casting or forging constraints, restricting the ability to produce intricate or highly customized components.

Cost Efficiency and Economic Factors

Powder metallurgy alloys typically offer superior cost efficiency compared to conventional alloys due to reduced material waste and lower energy consumption in production processes. The additive manufacturing capabilities inherent in powder metallurgy enable precise control over alloy composition, minimizing costly machining and post-processing steps. Economic factors favor powder metallurgy alloys in high-volume production where material savings and shorter cycle times significantly reduce overall manufacturing costs.

Environmental Impact and Sustainability

Powder metallurgy alloys significantly reduce material waste and energy consumption compared to conventional alloys due to their near-net shape manufacturing process. These alloys enable the recycling of metal powders and minimize greenhouse gas emissions, contributing to lower carbon footprints in production. Sustainable manufacturing practices in powder metallurgy support circular economy principles by enhancing resource efficiency and reducing the environmental impact of alloy production.

Typical Applications and Industry Use Cases

Powder metallurgy alloys excel in automotive and aerospace industries due to their superior wear resistance and precise microstructure control, making them ideal for components like gears, bearings, and turbine blades. Conventional alloys remain prevalent in construction and marine applications where bulk properties and cost-effectiveness take precedence. Manufacturing efficiency and material performance requirements drive the selection between powder metallurgy and conventional alloy processes across different industrial sectors.

Future Trends in Alloy Production Technologies

Powder metallurgy alloy technology enables precise control over microstructure and composition, promoting superior mechanical properties and reduced material waste compared to conventional alloy casting. Future trends highlight the integration of additive manufacturing with powder metallurgy, facilitating complex geometries and enhanced performance in aerospace and automotive industries. Advanced computational modeling and AI-driven process optimization are accelerating the development of customized alloys with improved strength, corrosion resistance, and lightweight characteristics.

Powder Metallurgy Alloy vs Conventional Alloy Infographic

materialdif.com

materialdif.com