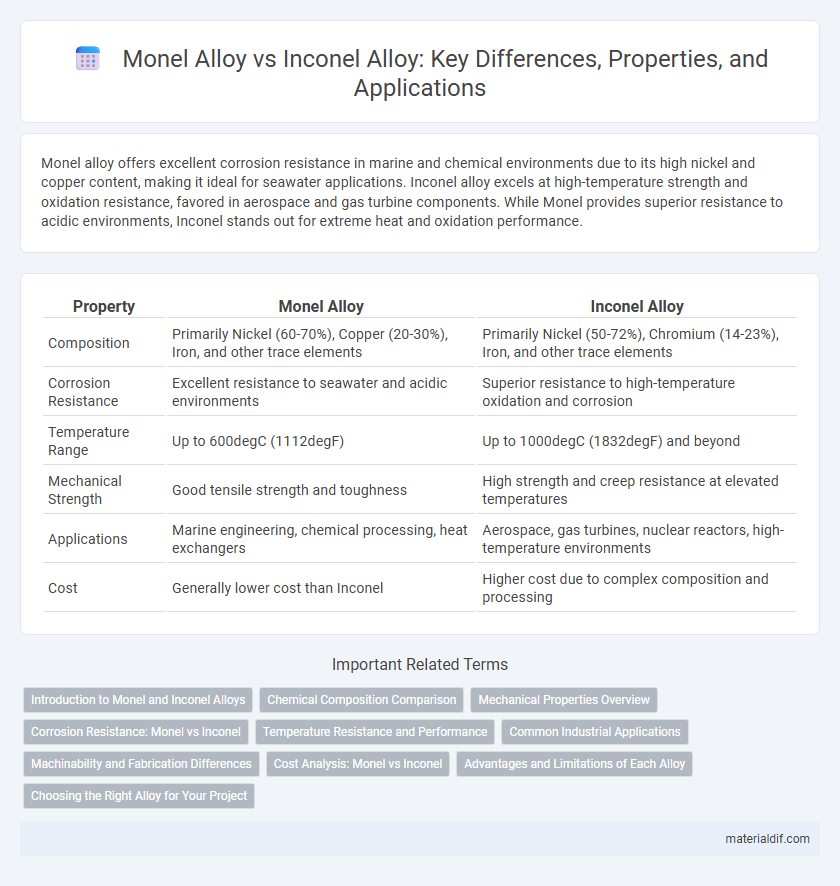

Monel alloy offers excellent corrosion resistance in marine and chemical environments due to its high nickel and copper content, making it ideal for seawater applications. Inconel alloy excels at high-temperature strength and oxidation resistance, favored in aerospace and gas turbine components. While Monel provides superior resistance to acidic environments, Inconel stands out for extreme heat and oxidation performance.

Table of Comparison

| Property | Monel Alloy | Inconel Alloy |

|---|---|---|

| Composition | Primarily Nickel (60-70%), Copper (20-30%), Iron, and other trace elements | Primarily Nickel (50-72%), Chromium (14-23%), Iron, and other trace elements |

| Corrosion Resistance | Excellent resistance to seawater and acidic environments | Superior resistance to high-temperature oxidation and corrosion |

| Temperature Range | Up to 600degC (1112degF) | Up to 1000degC (1832degF) and beyond |

| Mechanical Strength | Good tensile strength and toughness | High strength and creep resistance at elevated temperatures |

| Applications | Marine engineering, chemical processing, heat exchangers | Aerospace, gas turbines, nuclear reactors, high-temperature environments |

| Cost | Generally lower cost than Inconel | Higher cost due to complex composition and processing |

Introduction to Monel and Inconel Alloys

Monel alloy primarily consists of nickel and copper, known for its excellent corrosion resistance and high strength in marine and chemical environments. Inconel alloy is a nickel-chromium-based superalloy designed for extreme temperature resistance and oxidation stability, commonly used in aerospace and nuclear applications. Both alloys offer unique advantages with Monel excelling in corrosive environments and Inconel providing superior heat resistance.

Chemical Composition Comparison

Monel alloy primarily consists of 63% nickel and 28-34% copper, with small amounts of iron, manganese, and silicon, offering excellent resistance to seawater corrosion. In contrast, Inconel alloy is a nickel-chromium superalloy containing about 50-72% nickel, 14-23% chromium, along with iron, molybdenum, and cobalt, designed for high-temperature strength and oxidation resistance. The significant difference in copper content in Monel and chromium in Inconel defines their distinct chemical properties and industrial applications.

Mechanical Properties Overview

Monel alloy exhibits excellent tensile strength ranging from 70,000 to 85,000 psi and maintains superior toughness and ductility in cryogenic and high-temperature environments. Inconel alloy offers exceptional mechanical properties with tensile strength up to 120,000 psi and outstanding resistance to oxidation, creep, and thermal fatigue, particularly in extreme temperature ranges above 1,000degF. Both alloys are highly corrosion-resistant, but Monel is preferred for marine applications due to its copper-nickel content, while Inconel excels in aerospace and chemical processing industries for high-temperature performance.

Corrosion Resistance: Monel vs Inconel

Monel alloy exhibits exceptional corrosion resistance in marine and acidic environments due to its high nickel and copper content, making it ideal for seawater applications. Inconel alloy, composed primarily of nickel, chromium, and iron, offers superior oxidation and high-temperature corrosion resistance, particularly in harsh chemical and aerospace environments. While Monel excels against chloride ion-induced corrosion, Inconel provides enhanced resistance to scaling and carburization at elevated temperatures.

Temperature Resistance and Performance

Monel alloys exhibit excellent corrosion resistance and maintain strength at temperatures up to 1,000degF (538degC), making them suitable for marine and chemical environments. Inconel alloys outperform Monel in high-temperature resistance, with some grades like Inconel 718 maintaining mechanical properties and oxidation resistance above 1,300degF (704degC), ideal for aerospace and gas turbine applications. The superior temperature resistance of Inconel allows it to sustain structural integrity under extreme thermal stress, whereas Monel alloys are preferred for applications requiring moderate heat resistance combined with enhanced corrosion protection.

Common Industrial Applications

Monel alloy is extensively used in marine engineering, chemical processing, and aerospace applications due to its excellent corrosion resistance in seawater and acidic environments. Inconel alloy finds widespread application in high-temperature environments such as gas turbines, jet engines, and nuclear reactors because of its exceptional oxidation and heat resistance. Both alloys serve critical roles in industries requiring durability under extreme conditions, with Monel favored for its resilience against corrosion and Inconel for its superior strength at elevated temperatures.

Machinability and Fabrication Differences

Monel alloys, primarily composed of nickel and copper, exhibit excellent machinability due to their moderate work hardening rate and good thermal conductivity, making them suitable for intricate fabrication processes. Inconel alloys, predominantly nickel-chromium-based superalloys, present challenges in machining because of their high strength, corrosion resistance, and tendency to work harden rapidly, requiring specialized tooling and slower cutting speeds. Fabrication differences arise as Monel allows easier welding and forming, while Inconel demands advanced techniques like electron beam welding and controlled heat treatment to prevent cracking and maintain mechanical properties.

Cost Analysis: Monel vs Inconel

Monel alloy generally presents a lower initial cost compared to Inconel, making it a cost-effective choice for applications requiring moderate corrosion resistance and strength. Inconel alloy, known for exceptional high-temperature performance and oxidation resistance, incurs higher material and processing expenses due to its complex composition and manufacturing requirements. Total lifecycle cost analysis often favors Inconel where durability and resistance reduce maintenance and replacement frequency despite its higher upfront investment.

Advantages and Limitations of Each Alloy

Monel alloy offers superior corrosion resistance in marine and acidic environments, making it ideal for seawater applications and chemical processing, but it has limited high-temperature strength compared to Inconel. Inconel alloy excels in high-temperature oxidation resistance and maintains mechanical integrity under extreme heat, suitable for aerospace and power generation, yet it is more expensive and harder to machine than Monel. Both alloys provide excellent performance in specific conditions, requiring careful selection based on environmental exposure and mechanical demands.

Choosing the Right Alloy for Your Project

Monel alloy offers superior corrosion resistance in marine and chemical environments, making it ideal for applications requiring excellent resistance to saltwater and acids. Inconel alloy excels in high-temperature and oxidative conditions, particularly in aerospace and power generation industries, due to its strength and oxidation resistance. Selecting between Monel and Inconel alloys depends on project-specific factors such as exposure to corrosive agents, temperature range, and mechanical stress requirements.

Monel alloy vs Inconel alloy Infographic

materialdif.com

materialdif.com