Zinc alloy and Zamak both consist primarily of zinc but differ in composition and properties, impacting their application in manufacturing. Zinc alloys typically contain a mixture of metals like aluminum, copper, and magnesium, offering varied strength and corrosion resistance, whereas Zamak is a specific family of zinc alloys standardized with precise proportions of aluminum, magnesium, and copper for consistent performance. Zamak is favored for die-casting due to its excellent dimensional stability, smooth cast surface, and ease of fabrication, while general zinc alloys provide broader versatility in custom alloy formulations.

Table of Comparison

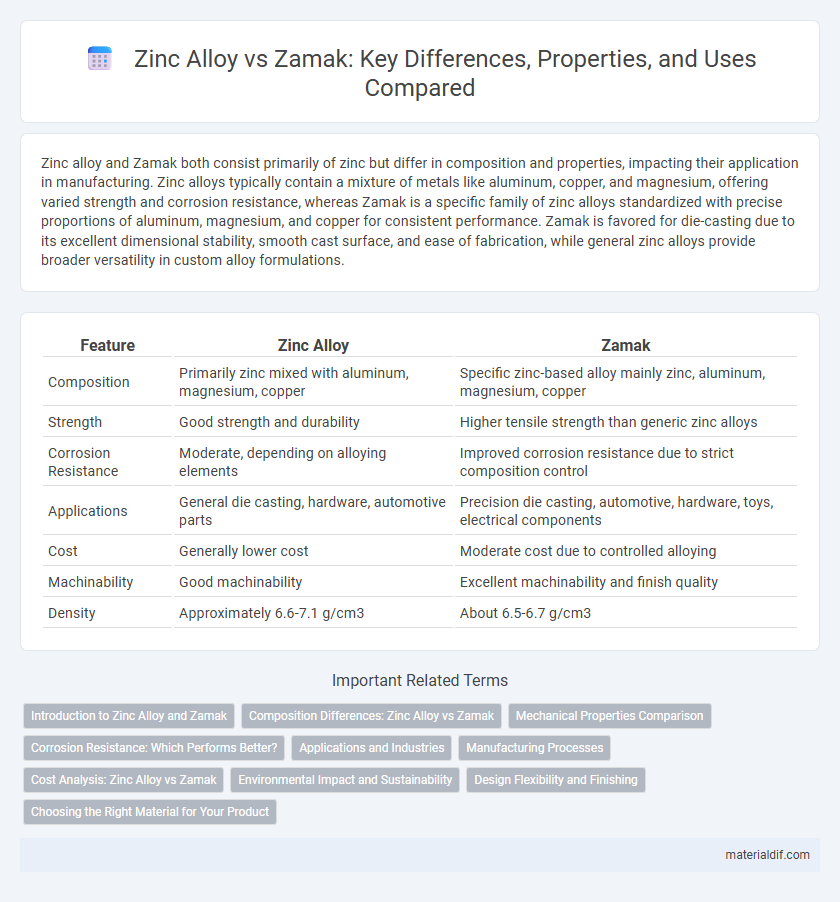

| Feature | Zinc Alloy | Zamak |

|---|---|---|

| Composition | Primarily zinc mixed with aluminum, magnesium, copper | Specific zinc-based alloy mainly zinc, aluminum, magnesium, copper |

| Strength | Good strength and durability | Higher tensile strength than generic zinc alloys |

| Corrosion Resistance | Moderate, depending on alloying elements | Improved corrosion resistance due to strict composition control |

| Applications | General die casting, hardware, automotive parts | Precision die casting, automotive, hardware, toys, electrical components |

| Cost | Generally lower cost | Moderate cost due to controlled alloying |

| Machinability | Good machinability | Excellent machinability and finish quality |

| Density | Approximately 6.6-7.1 g/cm3 | About 6.5-6.7 g/cm3 |

Introduction to Zinc Alloy and Zamak

Zinc alloy refers to a broad category of metal mixtures primarily composed of zinc combined with other elements like aluminum, copper, and magnesium, offering enhanced strength, flexibility, and corrosion resistance. Zamak is a specific type of zinc alloy standardized under the ZAMAK family, characterized by a precise composition of zinc with aluminum, magnesium, and copper, widely used in die casting for its excellent dimensional stability and smooth finish. Both materials serve critical roles in manufacturing, but Zamak is favored for applications requiring high precision and durability in parts such as automotive components and household hardware.

Composition Differences: Zinc Alloy vs Zamak

Zinc alloys typically comprise a blend of zinc with varying amounts of aluminum, copper, and magnesium to enhance strength and corrosion resistance, whereas Zamak consists primarily of zinc with fixed proportions of aluminum, magnesium, and copper, offering consistent mechanical properties. The aluminum content in Zamak ranges between 3-5%, improving casting fluidity and tensile strength compared to many general zinc alloys which may have lower aluminum percentages. Copper and magnesium in Zamak are precisely controlled to optimize hardness and durability, distinguishing it from broader zinc alloy categories that exhibit more variable elemental compositions.

Mechanical Properties Comparison

Zinc alloys exhibit varied mechanical properties depending on their composition and processing, with Zamak--a specific family of zinc-aluminum alloys--known for its superior tensile strength and hardness compared to general zinc alloys. Zamak alloys typically offer tensile strengths ranging from 270 to 400 MPa, enhanced wear resistance, and good dimensional stability, making them ideal for high-precision die-casting applications. In contrast, standard zinc alloys without aluminum may demonstrate lower mechanical performance but often provide better corrosion resistance and ductility.

Corrosion Resistance: Which Performs Better?

Zinc alloy and zamak both offer good corrosion resistance, but zamak generally performs better due to its highly refined composition and controlled manufacturing process. Zamak alloys, especially Zamak 3 and Zamak 5, contain optimized levels of zinc, aluminum, magnesium, and copper, enhancing their resistance to rust and environmental wear. Zinc alloy mixtures can vary widely, making their corrosion resistance less consistent compared to the standardized properties of zamak alloys.

Applications and Industries

Zinc alloys and Zamak are widely used in automotive, electronics, and construction industries due to their excellent strength and corrosion resistance. Zamak, a specific type of zinc alloy containing aluminum, magnesium, and copper, offers superior castability and uniformity, making it ideal for precision components in hardware and consumer electronics. Zinc alloys, with their versatility and cost-effectiveness, are preferred for decorative fittings, die-cast parts, and industrial machinery components.

Manufacturing Processes

Zinc alloy and Zamak differ primarily in their composition and manufacturing processes, with Zamak being a specific family of zinc alloys consisting mainly of zinc, aluminum, magnesium, and copper, optimized for die casting. Manufacturing processes for zinc alloys involve die casting, investment casting, and extrusion, where Zamak's precise alloy composition ensures excellent fluidity and mechanical strength during low-pressure die casting. The standardization of Zamak alloys (such as Zamak 3 and Zamak 5) facilitates consistent production quality, reducing defects and optimizing cycle times compared to broader zinc alloy variations.

Cost Analysis: Zinc Alloy vs Zamak

Zinc alloy and Zamak differ significantly in cost, with zinc alloy generally costing less due to its broader range of compositions and lower purity requirements. Zamak, a specific subset of zinc alloys composed primarily of zinc, aluminum, magnesium, and copper, tends to be more expensive because of its controlled composition and superior mechanical properties. Manufacturers often select zinc alloy for cost-sensitive applications while choosing Zamak for products demanding higher strength and precision, impacting the overall budgeting and material selection process in manufacturing.

Environmental Impact and Sustainability

Zinc alloy and Zamak differ significantly in environmental impact and sustainability, with Zamak often preferred for its standardized composition that facilitates recycling and lowers ecological footprint. Zinc alloy, containing higher zinc content and varied metals, can complicate recycling processes but still offers benefits due to zinc's abundant availability and low toxicity. Both materials contribute to sustainable manufacturing by enabling metal recovery and reducing reliance on virgin raw materials.

Design Flexibility and Finishing

Zinc alloy offers exceptional design flexibility due to its ability to be cast into intricate shapes with fine details, making it ideal for complex components. Zamak, a specific type of zinc alloy, provides superior finishing options, such as smooth surfaces and enhanced paint adhesion, which are crucial for aesthetic applications. Both materials support high-quality plating and coating processes, but Zamak's consistent composition ensures uniform finishes and durability.

Choosing the Right Material for Your Product

Zinc alloy offers excellent corrosion resistance and is highly versatile for intricate designs, making it ideal for durable consumer goods and hardware components. Zamak, a specific family of zinc alloys, provides superior mechanical strength and dimensional stability, often preferred in precision die casting for automotive and electronics applications. Selecting between zinc alloy and Zamak depends on factors like required strength, detail level, and environmental exposure to ensure optimal product performance and longevity.

Zinc Alloy vs Zamak Infographic

materialdif.com

materialdif.com