Alloy 20 excels in corrosion resistance against sulfuric acid and other reducing agents, making it ideal for chemical processing environments, while Hastelloy C276 provides superior performance against oxidizing agents and high-temperature applications due to its high nickel, molybdenum, and chromium content. Hastelloy C276 offers better resistance to pitting, crevice corrosion, and stress corrosion cracking compared to Alloy 20, which is more affordable and easier to machine. Selecting between these alloys depends on the specific chemical exposure, temperature conditions, and mechanical requirements of the application.

Table of Comparison

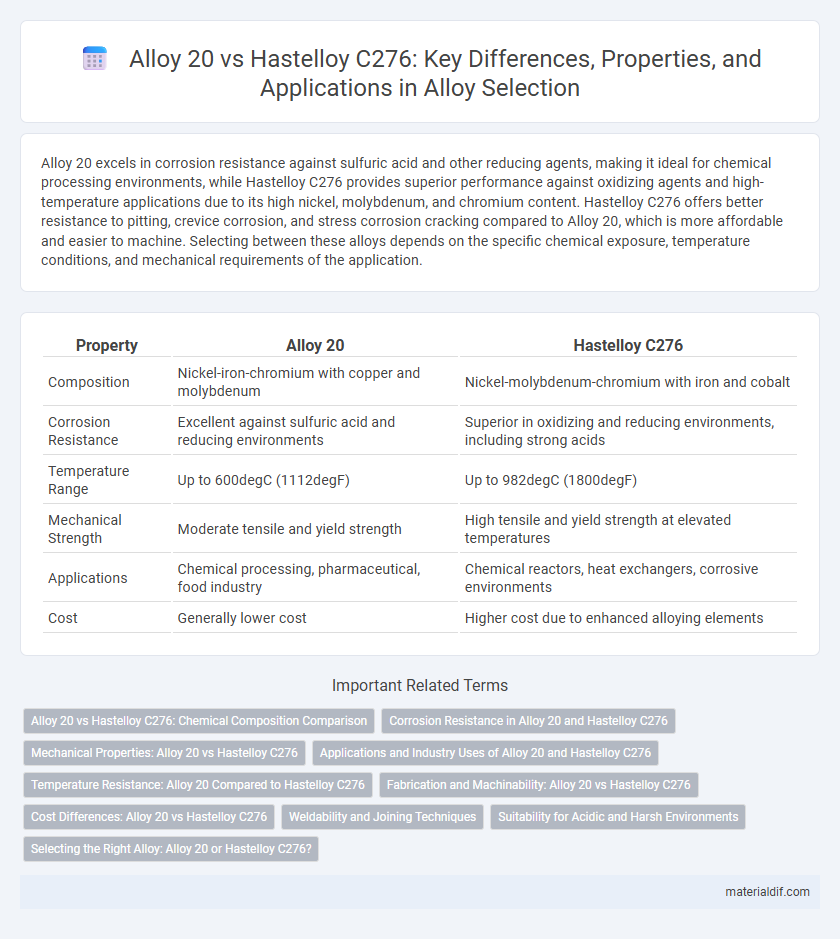

| Property | Alloy 20 | Hastelloy C276 |

|---|---|---|

| Composition | Nickel-iron-chromium with copper and molybdenum | Nickel-molybdenum-chromium with iron and cobalt |

| Corrosion Resistance | Excellent against sulfuric acid and reducing environments | Superior in oxidizing and reducing environments, including strong acids |

| Temperature Range | Up to 600degC (1112degF) | Up to 982degC (1800degF) |

| Mechanical Strength | Moderate tensile and yield strength | High tensile and yield strength at elevated temperatures |

| Applications | Chemical processing, pharmaceutical, food industry | Chemical reactors, heat exchangers, corrosive environments |

| Cost | Generally lower cost | Higher cost due to enhanced alloying elements |

Alloy 20 vs Hastelloy C276: Chemical Composition Comparison

Alloy 20 primarily consists of iron, nickel (30-35%), chromium (19-21%), copper (3-4%), and molybdenum (2-3%), offering excellent resistance to sulfuric acid and chloride-induced corrosion. Hastelloy C276 features a higher content of nickel (approximately 57%), with significant molybdenum (15-17%), chromium (14.5-16.5%), and smaller amounts of iron (4-7%), enhancing superior resistance to oxidizing and reducing environments. The distinct chemical compositions of Alloy 20 and Hastelloy C276 dictate their specialized applications in chemical processing, with Alloy 20 favored for moderate corrosion and Hastelloy C276 preferred for highly aggressive chemical conditions.

Corrosion Resistance in Alloy 20 and Hastelloy C276

Alloy 20 exhibits exceptional resistance to sulfuric acid, making it ideal for environments where strong acid corrosion is prevalent. Hastelloy C276 offers superior resistance to a wide range of aggressive chemicals, including oxidizing and reducing agents, due to its high nickel, molybdenum, and chromium content. Both alloys provide excellent corrosion resistance, but Alloy 20 is particularly suited for sulfuric acid applications, while Hastelloy C276 excels in highly corrosive, mixed acid environments.

Mechanical Properties: Alloy 20 vs Hastelloy C276

Alloy 20 exhibits a tensile strength of approximately 75 ksi and a yield strength near 35 ksi, making it suitable for moderate stress applications, while Hastelloy C276 offers higher tensile strength up to 90 ksi and yield strength around 40 ksi, supporting more demanding mechanical environments. The elongation percentage of Alloy 20 is roughly 30%, indicating good ductility compared to Hastelloy C276's 45%, which allows for greater deformation before failure. Both alloys demonstrate excellent hardness and resistance to stress corrosion cracking, with Hastelloy C276 generally favored for harsher chemical exposure due to superior mechanical robustness.

Applications and Industry Uses of Alloy 20 and Hastelloy C276

Alloy 20 is widely used in chemical processing, particularly for sulfuric acid environments, pharmaceuticals, and food processing industries due to its excellent resistance to strong reducing agents and intergranular corrosion. Hastelloy C276 is favored in aerospace, nuclear reactors, and marine applications for its superior resistance to oxidizing and reducing agents, including chlorides and strong acids. Both alloys serve critical roles in environments requiring high corrosion resistance but are selected based on specific chemical exposure and temperature conditions.

Temperature Resistance: Alloy 20 Compared to Hastelloy C276

Alloy 20 demonstrates strong corrosion resistance in temperatures up to approximately 600degF (316degC), making it suitable for moderate temperature applications involving sulfuric acid and other aggressive chemicals. Hastelloy C276, however, exhibits superior temperature resistance, maintaining structural integrity and corrosion resistance in environments reaching 1200degF (649degC) or higher. The higher temperature tolerance of Hastelloy C276 makes it the preferred choice for extreme heat conditions, while Alloy 20 is optimal for applications requiring moderate thermal endurance.

Fabrication and Machinability: Alloy 20 vs Hastelloy C276

Alloy 20 offers excellent weldability and moderate machinability, making it suitable for complex fabrications requiring resistance to sulfuric acid. Hastelloy C276, known for superior corrosion resistance, presents more challenges in machining due to its higher strength and work-hardening characteristics, often necessitating specialized tooling and slower cutting speeds. Fabrication of Hastelloy C276 demands precise control to avoid distortion, whereas Alloy 20 is generally more forgiving during forming and welding processes.

Cost Differences: Alloy 20 vs Hastelloy C276

Alloy 20 generally offers a lower cost compared to Hastelloy C276 due to its iron-rich composition and more abundant raw materials. Hastelloy C276, containing higher amounts of nickel and molybdenum, incurs increased production expenses, making it pricier in harsh chemical environments. Cost considerations often favor Alloy 20 for applications requiring corrosion resistance at moderate temperatures, while Hastelloy C276 suits extreme conditions despite its higher price point.

Weldability and Joining Techniques

Alloy 20 exhibits excellent weldability due to its stable austenitic structure and low carbon content, reducing the risk of carbide precipitation and intergranular corrosion during welding. Hastelloy C276 also offers good weldability but requires precise control of heat input and filler materials to prevent precipitation of harmful phases and maintain corrosion resistance. Both materials support common joining techniques such as TIG, MIG, and spot welding, with Alloy 20 favoring conventional welding and Hastelloy C276 often necessitating post-weld heat treatment for optimal joint performance.

Suitability for Acidic and Harsh Environments

Alloy 20 exhibits exceptional resistance to sulfuric acid and moderate acids, making it highly suitable for acidic environments in chemical processing. Hastelloy C276 outperforms in resisting both oxidizing and reducing agents, particularly in aggressive media containing chlorides and strong oxidizers. For harsh industrial conditions involving mixed acid and chloride exposure, Hastelloy C276 provides superior corrosion resistance and longevity compared to Alloy 20.

Selecting the Right Alloy: Alloy 20 or Hastelloy C276?

Alloy 20 offers excellent resistance to sulfuric acid and chloride-induced stress corrosion cracking, making it ideal for chemical processing environments with moderate to strong acid exposure. Hastelloy C276 provides superior resistance to a broad range of highly corrosive environments, including mixed acids and oxidizing agents, due to its high molybdenum and chromium content. Selection between Alloy 20 and Hastelloy C276 depends on the specific chemical exposure, temperature conditions, and cost considerations of the application.

Alloy 20 vs Hastelloy C276 Infographic

materialdif.com

materialdif.com