Zirconium alloy offers excellent corrosion resistance and high strength-to-weight ratio, making it ideal for medical implants and aerospace components. Tantalum alloy is highly valued for its superior biocompatibility and exceptional resistance to heat and chemical corrosion, frequently used in electronics and surgical instruments. Both alloys provide unique benefits depending on the application's specific demands for durability and performance.

Table of Comparison

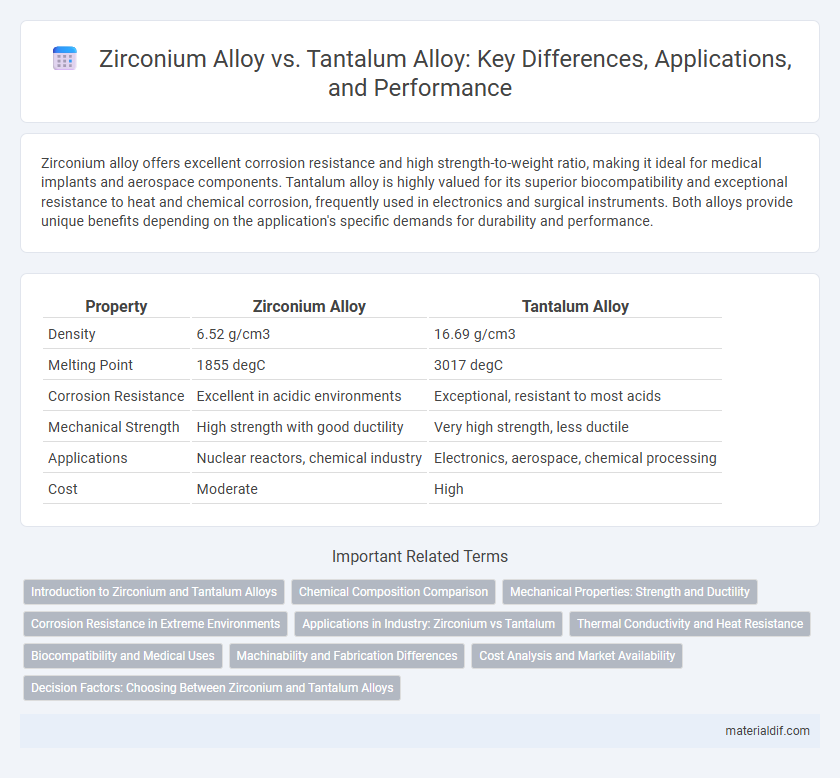

| Property | Zirconium Alloy | Tantalum Alloy |

|---|---|---|

| Density | 6.52 g/cm3 | 16.69 g/cm3 |

| Melting Point | 1855 degC | 3017 degC |

| Corrosion Resistance | Excellent in acidic environments | Exceptional, resistant to most acids |

| Mechanical Strength | High strength with good ductility | Very high strength, less ductile |

| Applications | Nuclear reactors, chemical industry | Electronics, aerospace, chemical processing |

| Cost | Moderate | High |

Introduction to Zirconium and Tantalum Alloys

Zirconium alloys are primarily used in nuclear reactors due to their low neutron absorption and high corrosion resistance, making them ideal for cladding fuel rods. Tantalum alloys exhibit exceptional resistance to corrosion and high temperatures, commonly applied in chemical processing and aerospace industries. Both alloys possess unique metallurgical properties that cater to specialized industrial applications requiring durability and stability under extreme conditions.

Chemical Composition Comparison

Zirconium alloys primarily consist of zirconium with small additions of tin, iron, chromium, and nickel, enhancing corrosion resistance and mechanical strength. Tantalum alloys contain tantalum as the base metal with minor amounts of tungsten, niobium, and hafnium, providing excellent corrosion resistance in aggressive environments. The distinct elemental compositions influence their specific applications, with zirconium alloys favored in nuclear reactors and tantalum alloys used in chemical processing equipment.

Mechanical Properties: Strength and Ductility

Zirconium alloy exhibits high strength and excellent corrosion resistance, making it suitable for demanding nuclear and chemical environments, while maintaining moderate ductility that facilitates fabrication. Tantalum alloy demonstrates superior strength combined with exceptional ductility and toughness, which enhances its performance in extreme temperature and corrosive conditions. Mechanical properties such as tensile strength and elongation highlight tantalum alloys' adaptability in aerospace and medical applications compared to zirconium alloys' reliability in structural components.

Corrosion Resistance in Extreme Environments

Zirconium alloys exhibit exceptional corrosion resistance in aggressive environments such as nuclear reactors and chemical processing due to their stable oxide layer formation. Tantalum alloys demonstrate superior resistance to highly acidic conditions, including hydrochloric and sulfuric acids, making them ideal for chemical engineering applications. Both alloys excel in extreme environments, but zirconium is preferred for high-temperature aqueous corrosion, while tantalum outperforms in acidic media corrosion resistance.

Applications in Industry: Zirconium vs Tantalum

Zirconium alloys are extensively used in nuclear reactors due to their low neutron absorption and excellent corrosion resistance in high-temperature water environments. Tantalum alloys find critical applications in aerospace and chemical processing industries, offering superior corrosion resistance and high melting points suitable for extreme environments. The choice between zirconium and tantalum alloys hinges on the specific industrial requirements of thermal stability, corrosion resistance, and mechanical strength.

Thermal Conductivity and Heat Resistance

Zirconium alloys exhibit moderate thermal conductivity, typically around 17 W/m*K, and exceptional heat resistance with melting points near 1855degC, making them suitable for high-temperature nuclear and aerospace applications. Tantalum alloys possess lower thermal conductivity, approximately 57 W/m*K, but offer superior heat resistance due to their high melting point of about 3017degC, ideal for extreme heat environments and corrosion-resistant uses. The choice between zirconium and tantalum alloys depends on the balance between thermal management requirements and the necessary thermal stability for specific industrial applications.

Biocompatibility and Medical Uses

Zirconium alloys exhibit excellent biocompatibility, corrosion resistance, and mechanical strength, making them ideal for dental implants, joint replacements, and cardiovascular devices. Tantalum alloys, known for their superior biocompatibility and high radiopacity, are extensively used in orthopedic implants and vascular stents, facilitating medical imaging and enhancing patient compatibility. Both alloys demonstrate critical properties for medical applications, with zirconium preferred for durability and tantalum for imaging and tissue integration.

Machinability and Fabrication Differences

Zirconium alloys exhibit superior machinability compared to tantalum alloys due to lower hardness and better thermal conductivity, allowing for faster cutting speeds and reduced tool wear. Tantalum alloys, known for their high melting point and excellent corrosion resistance, present challenges during fabrication, requiring slower machining processes and specialized tooling to avoid work hardening and surface damage. The distinct microstructures of zirconium and tantalum alloys influence their machinability, with zirconium providing greater ease in shaping and forming operations for industrial applications.

Cost Analysis and Market Availability

Zirconium alloys generally offer a more affordable cost structure compared to tantalum alloys, due to the wider availability of zirconium ore and lower processing expenses. Tantalum alloys command a premium price driven by their scarcity, complex extraction process, and specialized market demand in electronics and aerospace industries. Market availability for zirconium alloys is robust, supported by extensive mining operations, while tantalum alloys face supply constraints linked to geopolitical factors and limited extraction sources.

Decision Factors: Choosing Between Zirconium and Tantalum Alloys

Zirconium alloys exhibit superior corrosion resistance in nuclear reactors and enhanced thermal stability, making them ideal for high-temperature environments, whereas tantalum alloys provide exceptional ductility and corrosion resistance in chemical processing applications. Cost considerations favor zirconium alloys due to their relative abundance and lower production expenses compared to the rarer tantalum alloys. Mechanical properties, such as tensile strength and creep resistance, must be matched to specific operational demands when deciding between these two alloys.

Zirconium Alloy vs Tantalum Alloy Infographic

materialdif.com

materialdif.com