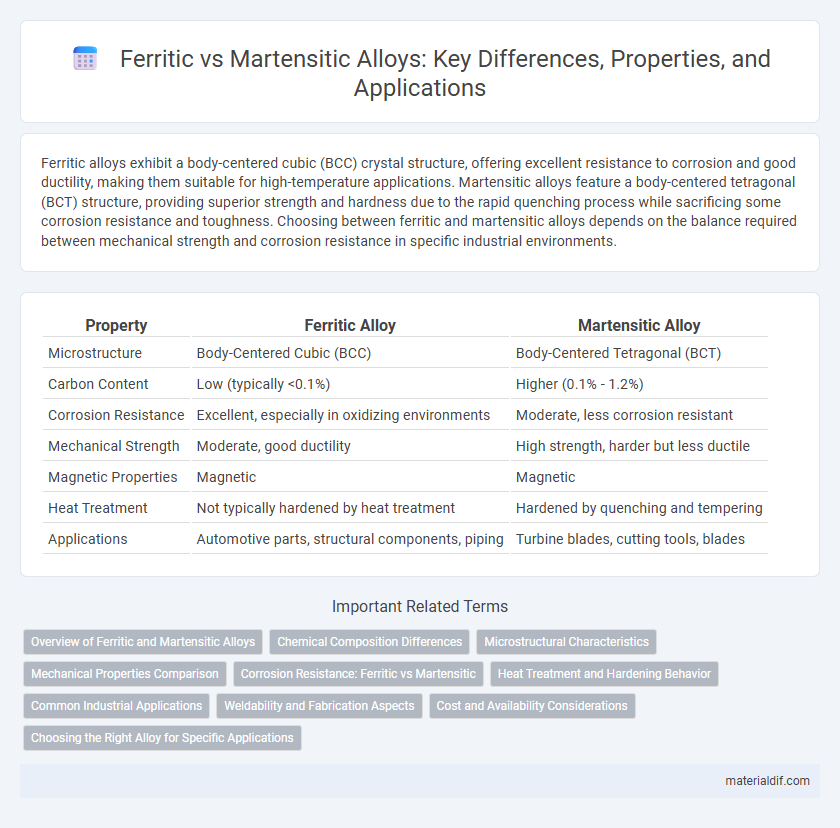

Ferritic alloys exhibit a body-centered cubic (BCC) crystal structure, offering excellent resistance to corrosion and good ductility, making them suitable for high-temperature applications. Martensitic alloys feature a body-centered tetragonal (BCT) structure, providing superior strength and hardness due to the rapid quenching process while sacrificing some corrosion resistance and toughness. Choosing between ferritic and martensitic alloys depends on the balance required between mechanical strength and corrosion resistance in specific industrial environments.

Table of Comparison

| Property | Ferritic Alloy | Martensitic Alloy |

|---|---|---|

| Microstructure | Body-Centered Cubic (BCC) | Body-Centered Tetragonal (BCT) |

| Carbon Content | Low (typically <0.1%) | Higher (0.1% - 1.2%) |

| Corrosion Resistance | Excellent, especially in oxidizing environments | Moderate, less corrosion resistant |

| Mechanical Strength | Moderate, good ductility | High strength, harder but less ductile |

| Magnetic Properties | Magnetic | Magnetic |

| Heat Treatment | Not typically hardened by heat treatment | Hardened by quenching and tempering |

| Applications | Automotive parts, structural components, piping | Turbine blades, cutting tools, blades |

Overview of Ferritic and Martensitic Alloys

Ferritic alloys primarily consist of iron with a body-centered cubic (BCC) crystal structure, offering excellent corrosion resistance and good ductility, making them suitable for automotive and industrial applications. Martensitic alloys feature a body-centered tetragonal (BCT) structure formed through rapid cooling, resulting in high strength and hardness, commonly used in aerospace and tooling industries. Both alloys differ significantly in heat treatment behavior, mechanical properties, and corrosion resistance, influencing their specific engineering applications.

Chemical Composition Differences

Ferritic alloys primarily contain high chromium content (typically 10.5% to 30%) with low carbon levels, enhancing corrosion resistance and magnetic properties. Martensitic alloys have lower chromium (usually 11-18%) but higher carbon content, which increases hardness and strength through heat treatment. The difference in carbon and chromium concentrations fundamentally affects their microstructure and mechanical behavior.

Microstructural Characteristics

Ferritic alloys feature a body-centered cubic (BCC) microstructure that provides excellent corrosion resistance and magnetic properties, with stable grain structures at high temperatures. Martensitic alloys exhibit a highly strained body-centered tetragonal (BCT) structure formed through rapid quenching, resulting in increased hardness and strength but reduced ductility. The differences in microstructural characteristics directly influence the performance and applications of these alloys in automotive, aerospace, and energy industries.

Mechanical Properties Comparison

Ferritic alloys exhibit higher corrosion resistance and better ductility compared to martensitic alloys, which typically have superior hardness and tensile strength due to their tempered microstructure. The lower carbon content in ferritic alloys results in enhanced toughness but reduced wear resistance relative to martensitic alloys engineered for high-strength applications. Martensitic alloys also demonstrate greater fatigue resistance, making them favorable in environments requiring mechanical stress endurance.

Corrosion Resistance: Ferritic vs Martensitic

Ferritic alloys exhibit superior corrosion resistance compared to martensitic alloys due to their higher chromium content and lower carbon levels, which reduce the formation of chromium carbides that can lead to intergranular corrosion. The body-centered cubic (BCC) structure of ferritic alloys also contributes to enhanced resistance to stress corrosion cracking. Martensitic alloys, while stronger and harder, are more prone to corrosion in harsh environments because their tempered microstructure and higher carbon content promote sensitization and oxide scale breakdown.

Heat Treatment and Hardening Behavior

Ferritic alloys, characterized by a body-centered cubic (BCC) structure, exhibit limited hardening through heat treatment due to the absence of a martensitic transformation, primarily relying on solid solution strengthening and grain refinement. Martensitic alloys undergo rapid quenching from the austenitizing temperature, transforming the face-centered cubic (FCC) structure of austenite into a hard and brittle body-centered tetragonal (BCT) martensite, significantly increasing hardness and strength. The heat treatment process for martensitic alloys typically involves austenitizing, quenching, and tempering to optimize the balance between hardness, toughness, and ductility.

Common Industrial Applications

Ferritic alloys are widely used in automotive exhaust systems, heat exchangers, and industrial gas turbines due to their excellent corrosion resistance and thermal stability. Martensitic alloys find common applications in cutting tools, aerospace components, and nuclear reactors because of their superior hardness, strength, and wear resistance. Both alloy types are essential in industries requiring a balance of mechanical properties and environmental durability.

Weldability and Fabrication Aspects

Ferritic alloys exhibit superior weldability due to their lower carbon content and stable ferrite microstructure, reducing the risk of cracking during fabrication. Martensitic alloys, characterized by higher carbon levels and a harder microstructure, present challenges such as increased susceptibility to weld heat-affected zone cracking and require preheating and post-weld heat treatment to maintain toughness. Fabrication of ferritic alloys is generally more straightforward with less distortion, while martensitic alloys demand precise control of welding parameters to avoid brittleness and ensure structural integrity.

Cost and Availability Considerations

Ferritic alloys generally offer lower production costs and greater availability due to their simpler manufacturing processes and widespread raw material sources, making them a cost-effective choice for large-scale applications. Martensitic alloys, though typically more expensive, provide enhanced mechanical properties and corrosion resistance, which justifies their higher price in specialized or high-performance uses. The balance between cost and availability often leads industries to select ferritic alloys for cost-sensitive projects and martensitic alloys when superior strength and durability are critical.

Choosing the Right Alloy for Specific Applications

Ferritic alloys excel in corrosion resistance and thermal stability, making them ideal for automotive exhaust systems and industrial furnaces, while martensitic alloys provide superior hardness and tensile strength suited for cutting tools and high-stress mechanical components. Selecting between ferritic and martensitic alloys depends on balancing the need for durability under thermal cycling against the requirement for structural strength and wear resistance. Understanding the microstructural differences and application environments ensures optimized performance and longevity in alloy selection.

Ferritic alloy vs Martensitic alloy Infographic

materialdif.com

materialdif.com