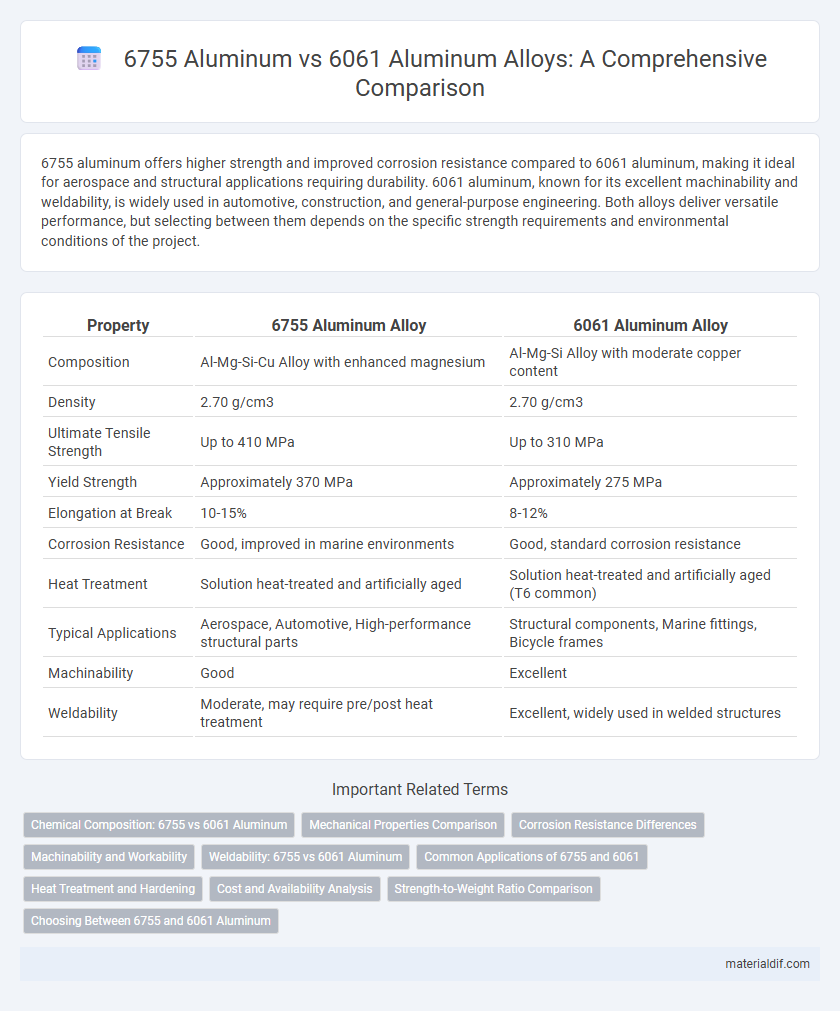

6755 aluminum offers higher strength and improved corrosion resistance compared to 6061 aluminum, making it ideal for aerospace and structural applications requiring durability. 6061 aluminum, known for its excellent machinability and weldability, is widely used in automotive, construction, and general-purpose engineering. Both alloys deliver versatile performance, but selecting between them depends on the specific strength requirements and environmental conditions of the project.

Table of Comparison

| Property | 6755 Aluminum Alloy | 6061 Aluminum Alloy |

|---|---|---|

| Composition | Al-Mg-Si-Cu Alloy with enhanced magnesium | Al-Mg-Si Alloy with moderate copper content |

| Density | 2.70 g/cm3 | 2.70 g/cm3 |

| Ultimate Tensile Strength | Up to 410 MPa | Up to 310 MPa |

| Yield Strength | Approximately 370 MPa | Approximately 275 MPa |

| Elongation at Break | 10-15% | 8-12% |

| Corrosion Resistance | Good, improved in marine environments | Good, standard corrosion resistance |

| Heat Treatment | Solution heat-treated and artificially aged | Solution heat-treated and artificially aged (T6 common) |

| Typical Applications | Aerospace, Automotive, High-performance structural parts | Structural components, Marine fittings, Bicycle frames |

| Machinability | Good | Excellent |

| Weldability | Moderate, may require pre/post heat treatment | Excellent, widely used in welded structures |

Chemical Composition: 6755 vs 6061 Aluminum

The chemical composition of 6755 aluminum includes higher levels of copper (1.5-2.0%) and zinc (3.0-4.0%), contributing to its enhanced strength and corrosion resistance compared to 6061 aluminum. In contrast, 6061 aluminum primarily consists of magnesium (0.8-1.2%) and silicon (0.4-0.8%), which offer good mechanical properties and weldability. The differing elemental concentrations in 6755 and 6061 alloys dictate their suitability for specific structural and automotive applications.

Mechanical Properties Comparison

6755 aluminum alloy offers higher tensile strength and better fatigue resistance compared to 6061 aluminum, making it suitable for demanding structural applications. The yield strength of 6755 typically exceeds 35,000 psi, while 6061 exhibits around 29,000 psi, highlighting its superior load-bearing capacity. 6061 aluminum provides greater corrosion resistance and easier weldability, but 6755's enhanced hardness and mechanical durability are preferred in aerospace and automotive industries.

Corrosion Resistance Differences

Alloy 6755 aluminum exhibits superior corrosion resistance compared to 6061 aluminum due to its enhanced magnesium and zinc content, which promotes better protection against oxidation and environmental degradation. The higher copper content in 6061 alloy makes it more prone to localized corrosion, especially in marine and industrial environments. For applications requiring prolonged exposure to harsh conditions, 6755 aluminum is a preferred choice for its improved durability and resistance to pitting corrosion.

Machinability and Workability

6755 aluminum offers superior machinability compared to 6061 aluminum due to its enhanced chemical composition, which allows for smoother cutting and less tool wear. In terms of workability, 6061 aluminum is more versatile and easier to form or weld, making it ideal for complex fabrication processes. Both alloys provide good strength-to-weight ratios, but 6755 excels in precision machining applications while 6061 is favored for structural and welding operations.

Weldability: 6755 vs 6061 Aluminum

6755 aluminum exhibits superior weldability compared to 6061 aluminum due to its lower silicon and iron content, reducing crack susceptibility during welding processes. The enhanced thermal conductivity and finer grain structure of 6755 alloy aid in producing stronger, cleaner welds with minimal distortion. In contrast, 6061 aluminum requires controlled heat input and post-weld heat treatment to prevent brittle phases, making it less favorable for high-stress welded applications.

Common Applications of 6755 and 6061

Grade 6755 aluminum is widely used in aerospace and automotive industries due to its high strength-to-weight ratio and excellent fatigue resistance, making it ideal for structural components and aircraft fittings. In contrast, 6061 aluminum is commonly found in construction, marine, and bicycle manufacturing because of its good corrosion resistance, machinability, and weldability. Both alloys serve essential roles in manufacturing where lightweight and durable materials are required, but 6755 is preferred for high-performance engineering applications while 6061 offers versatility in everyday industrial uses.

Heat Treatment and Hardening

6755 aluminum alloy undergoes heat treatment through precipitation hardening, which enhances its strength by forming fine particles within the metal matrix. 6061 aluminum alloy is also heat-treated using T6 temper, involving solution heat treatment followed by artificial aging to achieve a balance of strength and corrosion resistance. The hardening response of 6755 aluminum generally results in higher tensile strength compared to 6061 aluminum, making it suitable for applications requiring greater mechanical performance.

Cost and Availability Analysis

6755 aluminum generally costs more than 6061 aluminum due to its specialized alloying elements that enhance its mechanical properties. In terms of availability, 6061 aluminum is widely accessible and stocked by numerous suppliers globally, making it a more cost-effective and readily obtainable choice for most applications. The higher price and limited availability of 6755 aluminum reflect its niche use in aerospace and high-performance industrial applications.

Strength-to-Weight Ratio Comparison

6755 Aluminum offers a superior strength-to-weight ratio compared to 6061 Aluminum due to its higher tensile strength, typically around 510 MPa versus 310 MPa for 6061. Both alloys are commonly used in aerospace and structural applications, but 6755's enhanced strength allows for lighter, more efficient designs without compromising durability. Weight reduction in components made from 6755 Aluminum directly improves performance metrics where minimizing mass is critical.

Choosing Between 6755 and 6061 Aluminum

Choosing between 6755 aluminum and 6061 aluminum depends on specific applications and mechanical requirements. Alloy 6061 features excellent corrosion resistance, good weldability, and is widely used in structural components, whereas 6755 aluminum offers higher strength and improved performance in aerospace parts. Consider the balance of strength, machinability, and corrosion resistance to determine the best alloy for your project.

6755 Aluminum vs 6061 Aluminum Infographic

materialdif.com

materialdif.com