Duplex alloy features a balanced microstructure of austenite and ferrite, providing excellent corrosion resistance and high strength for applications in chemical processing and marine environments. Super duplex alloy enhances these properties with higher chromium, molybdenum, and nitrogen content, offering superior resistance to pitting, crevice corrosion, and stress corrosion cracking. Selecting between duplex and super duplex alloys depends on the specific environmental conditions and required performance, with super duplex preferred for more aggressive or demanding scenarios.

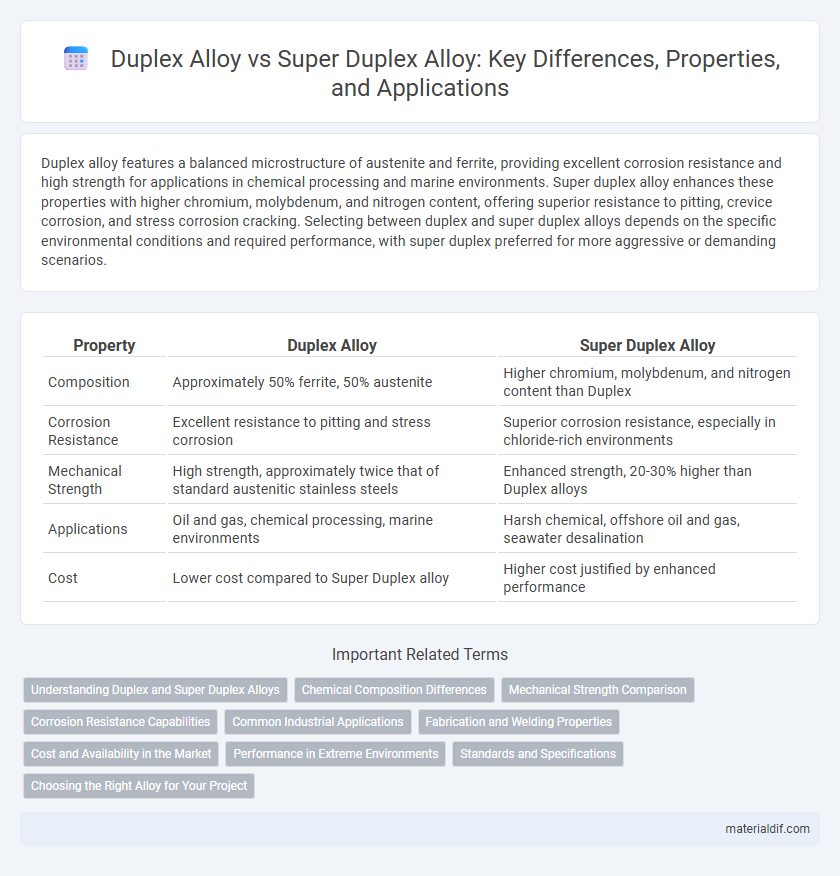

Table of Comparison

| Property | Duplex Alloy | Super Duplex Alloy |

|---|---|---|

| Composition | Approximately 50% ferrite, 50% austenite | Higher chromium, molybdenum, and nitrogen content than Duplex |

| Corrosion Resistance | Excellent resistance to pitting and stress corrosion | Superior corrosion resistance, especially in chloride-rich environments |

| Mechanical Strength | High strength, approximately twice that of standard austenitic stainless steels | Enhanced strength, 20-30% higher than Duplex alloys |

| Applications | Oil and gas, chemical processing, marine environments | Harsh chemical, offshore oil and gas, seawater desalination |

| Cost | Lower cost compared to Super Duplex alloy | Higher cost justified by enhanced performance |

Understanding Duplex and Super Duplex Alloys

Duplex alloys combine austenitic and ferritic stainless steels, offering enhanced strength and corrosion resistance, especially against stress corrosion cracking. Super duplex alloys contain higher levels of chromium, molybdenum, and nitrogen, which significantly improve their resistance to pitting, crevice corrosion, and mechanical properties at elevated temperatures. Both materials are widely used in the oil and gas industry for their durability in aggressive environments.

Chemical Composition Differences

Duplex alloy typically contains around 22-25% chromium, 5-7% nickel, and 2.5-3% molybdenum, offering a balanced blend of corrosion resistance and strength. Super duplex alloys enhance these properties by increasing chromium content to 24-26%, nickel to 6-8%, and molybdenum to 3-5%, resulting in superior resistance to pitting and crevice corrosion. The higher nitrogen levels in super duplex alloys further improve mechanical properties and resistance to stress corrosion cracking compared to standard duplex alloys.

Mechanical Strength Comparison

Duplex alloys typically exhibit tensile strengths ranging from 550 to 700 MPa, while super duplex alloys offer enhanced mechanical strength, often exceeding 800 MPa due to higher chromium and molybdenum content. The improved phase balance in super duplex alloys contributes to superior yield strength and hardness compared to standard duplex grades. This increased mechanical strength makes super duplex alloys ideal for demanding environments requiring enhanced corrosion resistance and structural integrity.

Corrosion Resistance Capabilities

Duplex alloy offers excellent corrosion resistance, particularly in chloride-rich environments, combining ferritic and austenitic properties to resist stress corrosion cracking and pitting. Super duplex alloy enhances these capabilities with higher chromium, molybdenum, and nitrogen content, providing superior resistance to localized corrosion such as crevice corrosion and stress corrosion cracking in aggressive industrial settings. The advanced microstructure of super duplex alloys ensures extended durability in harsh environments, making them ideal for offshore oil and gas applications requiring maximum corrosion protection.

Common Industrial Applications

Duplex alloy finds widespread use in chemical processing, oil and gas pipelines, and marine environments due to its excellent corrosion resistance and strength. Super duplex alloy, with higher alloying content and enhanced mechanical properties, is ideal for highly aggressive environments such as offshore oil rigs, heat exchangers, and seawater desalination plants. Both alloys serve critical roles in industries requiring durability against stress corrosion cracking and chloride-induced corrosion.

Fabrication and Welding Properties

Duplex Alloy offers excellent weldability with balanced austenitic and ferritic microstructures, enabling straightforward fabrication and reduced risk of cracking during welding. Super Duplex Alloy provides superior strength and corrosion resistance but requires precise control of heat input and interpass temperature during welding to avoid phase imbalance and stress corrosion cracking. Both alloys demand specialized welding techniques such as gas tungsten arc welding (GTAW) to maintain mechanical integrity and optimize joint performance.

Cost and Availability in the Market

Duplex alloy generally offers lower cost and wider availability in the market compared to super duplex alloy, making it a more economical choice for many industrial applications. Super duplex alloy, with its higher resistance to corrosion and enhanced mechanical properties, commands a premium price and is less commonly stocked by suppliers. Market demand for super duplex alloy remains niche, driving its cost upward and limiting immediate availability.

Performance in Extreme Environments

Duplex Alloy offers excellent corrosion resistance and strength in extreme environments, particularly in chloride-rich or seawater applications. Super Duplex Alloy enhances these properties with higher chromium, molybdenum, and nitrogen content, delivering superior resistance to pitting, crevice corrosion, and stress corrosion cracking. Performance in high-temperature and highly corrosive conditions is significantly improved in Super Duplex due to its advanced microstructure and increased phase balance.

Standards and Specifications

Duplex alloy and super duplex alloy differ significantly in their standards and specifications, with Duplex alloys typically conforming to ASTM A790 and A182 standards, ensuring balanced corrosion resistance and strength. Super duplex alloys meet more stringent specifications like ASTM A995 and A240, designed for higher pitting resistance and enhanced mechanical properties in aggressive environments. The higher chromium and molybdenum content in super duplex alloys directly influences compliance with these elevated standards, making them suitable for offshore and chemical processing applications.

Choosing the Right Alloy for Your Project

Duplex alloys offer excellent corrosion resistance and high strength, making them ideal for moderate industrial applications, while Super Duplex alloys provide enhanced resistance to pitting, crevice corrosion, and stress corrosion cracking, suitable for more aggressive environments. Selecting the right alloy depends on factors such as chloride concentration, temperature, and mechanical stress in the project conditions. For projects involving offshore or chemical processing settings, Super Duplex alloys ensure superior longevity and reliability compared to standard Duplex alloys.

Duplex Alloy vs Super Duplex Alloy Infographic

materialdif.com

materialdif.com