Zamak and Mazak are both zinc-based alloys known for their excellent casting properties and corrosion resistance, with Zamak primarily composed of zinc, aluminum, magnesium, and copper, while Mazak often includes higher copper content for enhanced strength. Zamak's fine surface finish and dimensional stability make it ideal for precision die-casting applications, whereas Mazak offers superior mechanical strength, making it suitable for more demanding structural components. Manufacturers select between Zamak and Mazak based on specific performance requirements such as strength, ductility, and cost efficiency in various industrial contexts.

Table of Comparison

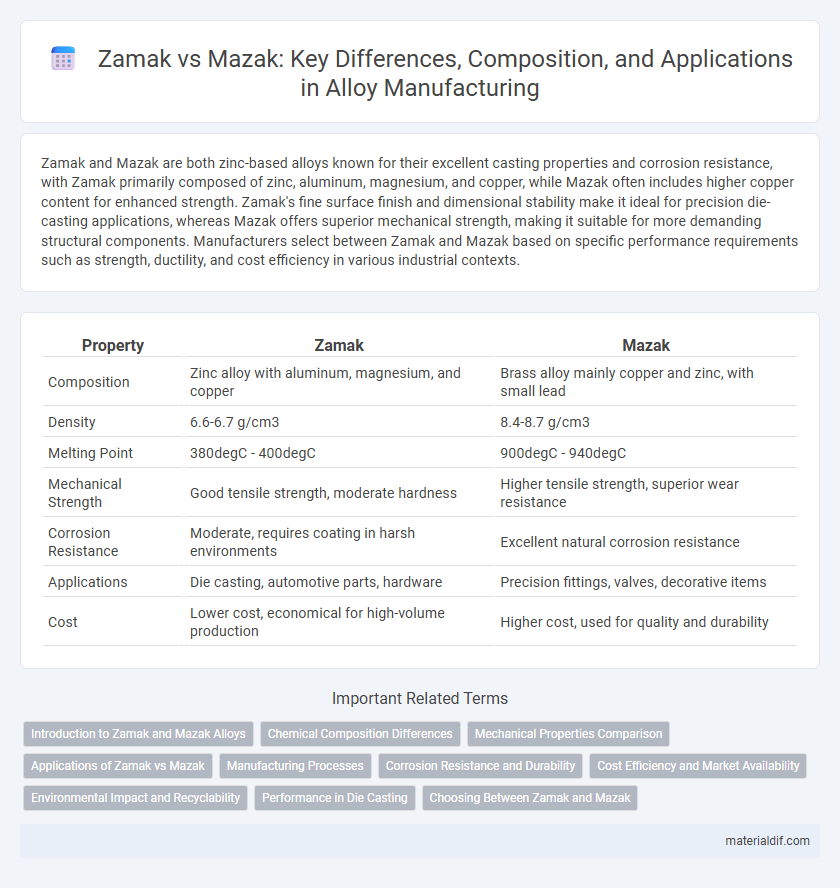

| Property | Zamak | Mazak |

|---|---|---|

| Composition | Zinc alloy with aluminum, magnesium, and copper | Brass alloy mainly copper and zinc, with small lead |

| Density | 6.6-6.7 g/cm3 | 8.4-8.7 g/cm3 |

| Melting Point | 380degC - 400degC | 900degC - 940degC |

| Mechanical Strength | Good tensile strength, moderate hardness | Higher tensile strength, superior wear resistance |

| Corrosion Resistance | Moderate, requires coating in harsh environments | Excellent natural corrosion resistance |

| Applications | Die casting, automotive parts, hardware | Precision fittings, valves, decorative items |

| Cost | Lower cost, economical for high-volume production | Higher cost, used for quality and durability |

Introduction to Zamak and Mazak Alloys

Zamak is a family of zinc-based alloys primarily composed of zinc, aluminum, magnesium, and copper, known for excellent casting properties, corrosion resistance, and mechanical strength. Mazak, often confused with Zamak, refers to a specialized zinc alloy with variations in composition designed for specific industrial applications requiring enhanced durability and surface finish. Both alloys are widely used in die-casting processes for automotive, hardware, and consumer goods, offering cost-effective solutions with high dimensional stability.

Chemical Composition Differences

Zamak and Mazak are zinc-based alloys primarily composed of zinc, aluminum, magnesium, and copper, but their chemical compositions differ notably. Zamak typically contains about 4% aluminum, 0.03% magnesium, and 0.25% copper, whereas Mazak has a higher copper content, often around 3-5%, with aluminum ranging between 3-5% and minimal magnesium. These differences in chemical composition affect their mechanical properties, corrosion resistance, and casting behavior, making Zamak more suitable for precision die casting and Mazak preferred for applications requiring enhanced strength and wear resistance.

Mechanical Properties Comparison

Zamak alloys, known for their excellent casting properties, typically exhibit tensile strengths ranging from 270 to 370 MPa and have good ductility with elongation up to 8%, making them suitable for intricate die-casting applications. Mazak alloys, a subset of zinc-aluminum alloys, generally offer higher tensile strength, up to 450 MPa, along with improved hardness and abrasion resistance, which enhances their performance in wear-resistant components. Both alloys provide moderate corrosion resistance, but Mazak's enhanced mechanical properties make it preferable for applications requiring superior strength and durability.

Applications of Zamak vs Mazak

Zamak alloys are predominantly used in die casting for automotive parts, household hardware, and electrical components due to their excellent dimensional stability and corrosion resistance. Mazak, a trade name often confused with Zamak, typically refers to specific proprietary zinc-aluminum alloys favored in precision engineering and high-strength applications such as gears and industrial machinery components. Zamak's superior fluidity and ease of casting make it ideal for intricate molds, while Mazak alloys offer enhanced mechanical properties for load-bearing and wear-resistant parts.

Manufacturing Processes

Zamak, predominantly composed of zinc with aluminum, magnesium, and copper, excels in die casting due to its low melting point and excellent fluidity, enabling intricate shapes with tight tolerances. Mazak, often a brand name for specific machining alloys like free-cutting brass, is favored for precision machining processes requiring high machinability and minimal tool wear. In manufacturing, Zamak's suitability for rapid, high-volume production contrasts with Mazak's optimal performance in CNC turning, milling, and drilling operations where fine detail and surface finish are critical.

Corrosion Resistance and Durability

Zamak alloys exhibit superior corrosion resistance due to higher zinc content combined with aluminum, enhancing their durability in harsh environments compared to Mazak, which contains less zinc and more impurities. The microstructure of Zamak provides a uniform protective oxide layer, significantly reducing susceptibility to rust and wear over time. Consequently, Zamak is often preferred in applications requiring long-term reliability and resistance to environmental degradation.

Cost Efficiency and Market Availability

Zamak alloys, primarily composed of zinc with aluminum, magnesium, and copper, offer superior cost efficiency due to lower raw material prices and ease of casting, making them ideal for mass production in automotive and hardware industries. Mazak, often considered synonymous with Zamak but sometimes referring to specific proprietary blends, may have higher costs linked to specialized properties or limited suppliers, affecting market availability. The widespread production and standardized specifications of Zamak ensure broader market availability and competitive pricing compared to the more niche or custom variants labeled as Mazak.

Environmental Impact and Recyclability

Zamak, primarily composed of zinc with aluminum, magnesium, and copper, offers excellent recyclability with lower energy consumption during melting compared to Mazak, a trade name often associated with more complex zinc alloys. Zamak's production results in reduced greenhouse gas emissions and leaching risks, whereas Mazak may contain elements that complicate recycling and environmental disposal. Both alloys provide valuable metal recovery options, but Zamak's simpler composition gives it a distinct advantage in minimizing environmental impact.

Performance in Die Casting

Zamak, primarily composed of zinc with aluminum, magnesium, and copper, offers excellent fluidity and low melting points, making it ideal for intricate die casting applications requiring tight tolerances and smooth finishes. Mazak, a form of zinc-aluminum alloy with higher aluminum content, provides superior strength, hardness, and heat resistance, enhancing durability in high-stress die-cast parts. Choosing between Zamak and Mazak depends on balancing performance factors such as mechanical strength, corrosion resistance, and cost-efficiency for specific die casting requirements.

Choosing Between Zamak and Mazak

Choosing between Zamak and Mazak alloys depends on the application's mechanical and thermal requirements. Zamak offers excellent corrosion resistance and is ideal for die-casting precision components with moderate strength, while Mazak provides higher tensile strength and better wear resistance for heavy-duty parts. Evaluating factors such as load-bearing capacity, environmental exposure, and cost efficiency ensures optimal material selection for manufacturing success.

Zamak vs Mazak Infographic

materialdif.com

materialdif.com