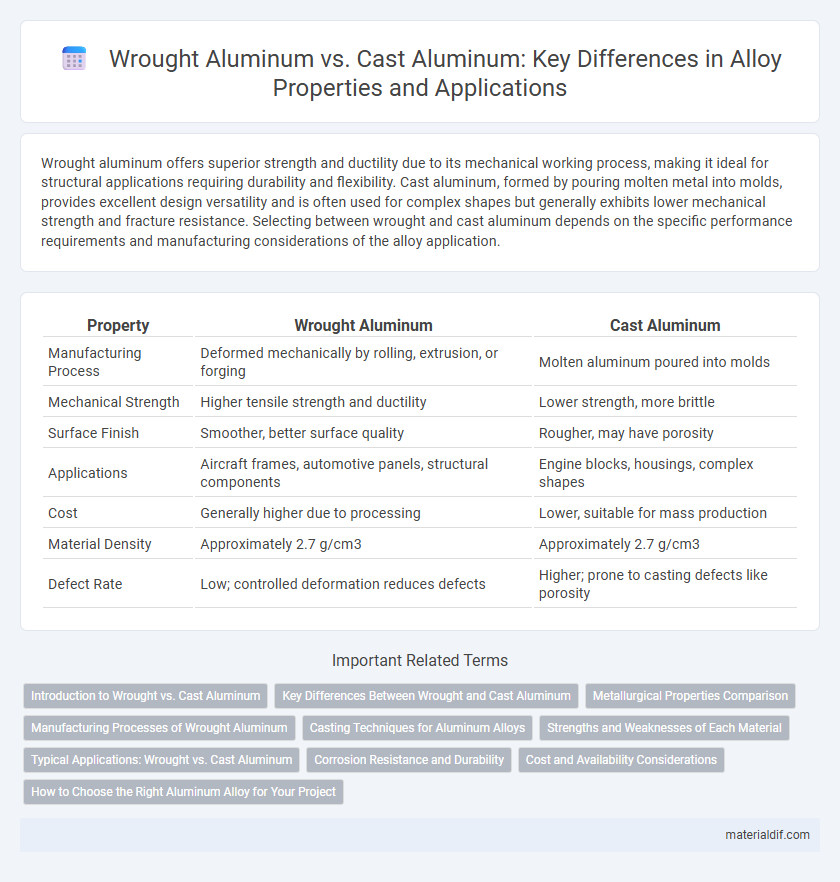

Wrought aluminum offers superior strength and ductility due to its mechanical working process, making it ideal for structural applications requiring durability and flexibility. Cast aluminum, formed by pouring molten metal into molds, provides excellent design versatility and is often used for complex shapes but generally exhibits lower mechanical strength and fracture resistance. Selecting between wrought and cast aluminum depends on the specific performance requirements and manufacturing considerations of the alloy application.

Table of Comparison

| Property | Wrought Aluminum | Cast Aluminum |

|---|---|---|

| Manufacturing Process | Deformed mechanically by rolling, extrusion, or forging | Molten aluminum poured into molds |

| Mechanical Strength | Higher tensile strength and ductility | Lower strength, more brittle |

| Surface Finish | Smoother, better surface quality | Rougher, may have porosity |

| Applications | Aircraft frames, automotive panels, structural components | Engine blocks, housings, complex shapes |

| Cost | Generally higher due to processing | Lower, suitable for mass production |

| Material Density | Approximately 2.7 g/cm3 | Approximately 2.7 g/cm3 |

| Defect Rate | Low; controlled deformation reduces defects | Higher; prone to casting defects like porosity |

Introduction to Wrought vs. Cast Aluminum

Wrought aluminum is produced by mechanically shaping heated aluminum through processes such as rolling, extrusion, or forging, resulting in enhanced strength and ductility due to grain refinement. Cast aluminum involves pouring molten aluminum into molds, creating complex shapes but often with lower mechanical properties compared to wrought forms. The distinction between wrought and cast aluminum fundamentally impacts their applications, where wrought aluminum is preferred for structural components requiring higher strength and cast aluminum suits intricate, less load-bearing parts.

Key Differences Between Wrought and Cast Aluminum

Wrought aluminum is mechanically shaped through processes like rolling, extrusion, or forging, resulting in a dense, uniform microstructure with superior strength and ductility. Cast aluminum is produced by pouring molten metal into molds, leading to a more porous microstructure that offers better complex shape formation but lower mechanical strength. Key differences include the manufacturing methods, mechanical properties, and typical applications, with wrought aluminum preferred for high-strength structural components and cast aluminum used in intricate parts requiring good corrosion resistance.

Metallurgical Properties Comparison

Wrought aluminum exhibits superior mechanical strength and ductility due to its refined grain structure achieved through rolling or forging processes, enhancing fatigue resistance and toughness. Cast aluminum features a coarser microstructure with higher porosity, resulting in lower tensile strength but improved castability and complex shape formation. Metallurgically, wrought aluminum alloys benefit from work hardening and grain alignment, whereas cast alloys rely on solidification control to optimize properties.

Manufacturing Processes of Wrought Aluminum

Wrought aluminum undergoes mechanical working processes such as rolling, extrusion, forging, and drawing, which refine the metal's grain structure and enhance its strength and ductility compared to cast aluminum. These manufacturing methods involve deforming the aluminum billet under controlled temperature and pressure conditions to achieve desired shapes and improved mechanical properties. The resulting microstructure from these processes offers superior fatigue resistance, making wrought aluminum ideal for aerospace, automotive, and structural applications.

Casting Techniques for Aluminum Alloys

Wrought aluminum involves mechanical working processes like rolling or extrusion that enhance grain structure and strength, while cast aluminum is produced by pouring molten metal into molds, allowing for complex shapes but varying mechanical properties. Casting techniques for aluminum alloys include sand casting, die casting, and investment casting, each offering unique benefits in terms of surface finish, dimensional accuracy, and production speed. Die casting is particularly favored for high-volume production due to its precise tolerances and smooth finishes, whereas sand casting is more versatile for large parts and low-volume runs.

Strengths and Weaknesses of Each Material

Wrought aluminum features superior strength and ductility due to its grain structure refinement during mechanical working, making it ideal for applications requiring high tensile strength and fatigue resistance. Cast aluminum offers excellent corrosion resistance and design flexibility, allowing complex shapes with good thermal conductivity, but typically has lower mechanical strength and is more prone to porosity and shrinkage defects. Selection depends on balancing performance requirements against manufacturing costs and intended use conditions.

Typical Applications: Wrought vs. Cast Aluminum

Wrought aluminum alloys are typically used in applications requiring high strength and excellent ductility, such as aerospace components, automotive parts, and structural frameworks. Cast aluminum alloys find common use in complex-shaped parts like engine blocks, housings, and machinery components where intricate designs and good wear resistance are critical. The choice between wrought and cast aluminum largely depends on the mechanical property requirements and geometric complexity of the part.

Corrosion Resistance and Durability

Wrought aluminum exhibits superior corrosion resistance due to its refined grain structure and fewer casting defects, which enhances its durability in harsh environments. Cast aluminum often contains microporosity and inclusions that can act as corrosion initiation sites, reducing its long-term performance. The enhanced mechanical properties and corrosion resistance of wrought aluminum make it ideal for structural applications requiring longevity and reliability.

Cost and Availability Considerations

Wrought aluminum typically incurs higher costs due to its labor-intensive manufacturing process and greater material strength, making it preferred for applications requiring superior mechanical properties. Cast aluminum offers lower production expenses and widespread availability through mold-based fabrication, ideal for complex shapes and large-scale manufacturing. Cost efficiency and accessibility drive material selection, with cast aluminum favored for budget-conscious projects and wrought aluminum chosen when performance outweighs initial investment.

How to Choose the Right Aluminum Alloy for Your Project

Wrought aluminum offers superior strength and flexibility due to its grain structure alignment, making it ideal for applications requiring high durability and formability, such as aerospace and automotive components. Cast aluminum, while generally less strong, excels in complex shapes and intricate designs due to its fluidity during casting, suitable for engine blocks and housings. Selecting the right aluminum alloy depends on balancing mechanical properties, fabrication methods, and project requirements to ensure optimal performance and cost-efficiency.

Wrought aluminum vs Cast aluminum Infographic

materialdif.com

materialdif.com