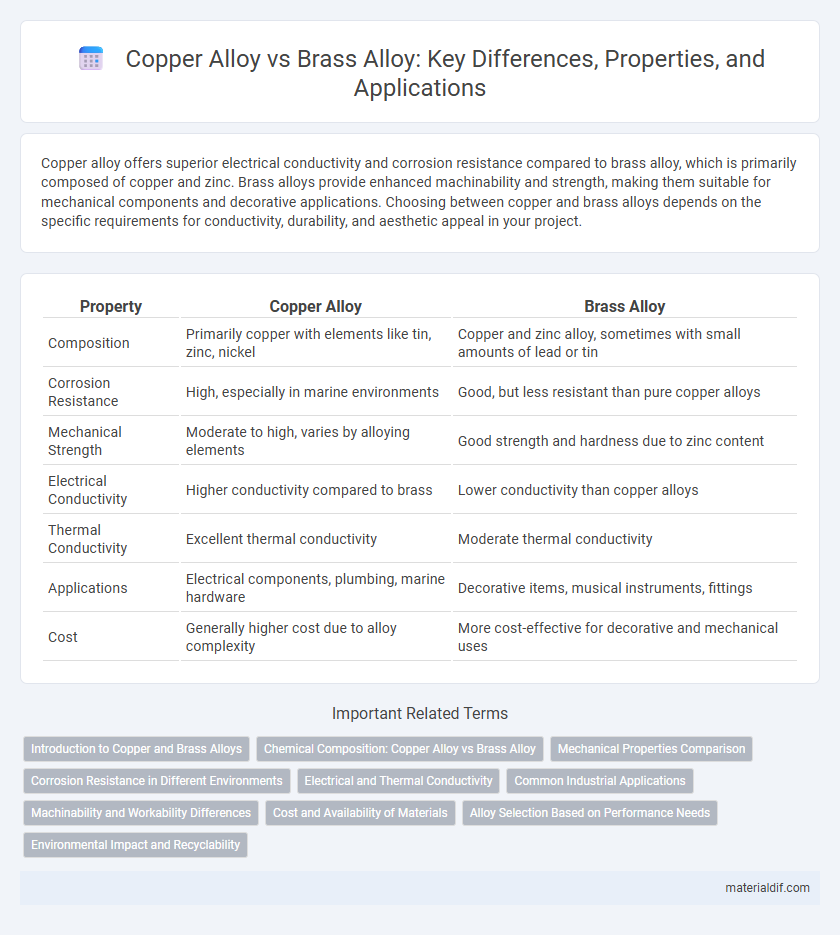

Copper alloy offers superior electrical conductivity and corrosion resistance compared to brass alloy, which is primarily composed of copper and zinc. Brass alloys provide enhanced machinability and strength, making them suitable for mechanical components and decorative applications. Choosing between copper and brass alloys depends on the specific requirements for conductivity, durability, and aesthetic appeal in your project.

Table of Comparison

| Property | Copper Alloy | Brass Alloy |

|---|---|---|

| Composition | Primarily copper with elements like tin, zinc, nickel | Copper and zinc alloy, sometimes with small amounts of lead or tin |

| Corrosion Resistance | High, especially in marine environments | Good, but less resistant than pure copper alloys |

| Mechanical Strength | Moderate to high, varies by alloying elements | Good strength and hardness due to zinc content |

| Electrical Conductivity | Higher conductivity compared to brass | Lower conductivity than copper alloys |

| Thermal Conductivity | Excellent thermal conductivity | Moderate thermal conductivity |

| Applications | Electrical components, plumbing, marine hardware | Decorative items, musical instruments, fittings |

| Cost | Generally higher cost due to alloy complexity | More cost-effective for decorative and mechanical uses |

Introduction to Copper and Brass Alloys

Copper alloys primarily consist of copper combined with elements such as zinc, tin, aluminum, and nickel, enhancing corrosion resistance and electrical conductivity for various industrial applications. Brass alloys are a specific type of copper alloy mainly composed of copper and zinc, known for their excellent machinability, antimicrobial properties, and attractive gold-like appearance. Both copper and brass alloys are widely used in manufacturing, plumbing, and decorative arts due to their durability and versatile mechanical properties.

Chemical Composition: Copper Alloy vs Brass Alloy

Copper alloy primarily consists of copper combined with elements like zinc, tin, aluminum, and nickel, with copper content typically exceeding 60%. Brass alloy is a specific type of copper alloy mainly composed of copper and zinc, usually containing 55-95% copper and 5-45% zinc by weight. The distinct chemical composition of brass, characterized by its higher zinc concentration, provides improved machinability and corrosion resistance compared to other copper alloys.

Mechanical Properties Comparison

Copper alloys typically exhibit higher ductility and better electrical conductivity compared to brass alloys, which are an alloy of copper and zinc. Brass alloys generally offer greater tensile strength and improved corrosion resistance, making them suitable for structural applications and marine environments. When selecting between copper and brass alloys, factors such as mechanical strength, machinability, and environmental conditions play critical roles in determining the optimal material choice.

Corrosion Resistance in Different Environments

Copper alloys generally offer superior corrosion resistance in marine and acidic environments due to their higher copper content, which forms a protective oxide layer. Brass alloys, composed mainly of copper and zinc, are more susceptible to dezincification and corrosion in chloride-rich or alkaline conditions. Selecting the appropriate alloy depends on specific environmental factors, with copper alloys favored for enhanced durability in harsh, corrosive settings.

Electrical and Thermal Conductivity

Copper alloys generally exhibit higher electrical and thermal conductivity compared to brass alloys due to their higher copper content. Brass alloys, composed primarily of copper and zinc, have reduced conductivity as zinc lowers both electrical and thermal transfer efficiency. Applications requiring superior conductivity, such as electrical wiring and heat exchangers, often favor copper alloys over brass alloys.

Common Industrial Applications

Copper alloy and brass alloy are extensively used in industrial applications due to their excellent corrosion resistance and electrical conductivity. Copper alloys find common use in electrical wiring, heat exchangers, and plumbing components, while brass alloys are favored for precision instruments, marine hardware, and decorative fittings. The choice between copper and brass alloys depends on specific performance requirements such as strength, machinability, and resistance to environmental conditions.

Machinability and Workability Differences

Copper alloy offers superior corrosion resistance but generally exhibits lower machinability compared to brass alloys, which contain zinc as the primary alloying element. Brass alloys provide enhanced workability due to their softer nature and better chip formation during machining, resulting in smoother cutting and reduced tool wear. When selecting between copper and brass alloys, machinability and ease of fabrication are critical factors influencing production efficiency and component performance.

Cost and Availability of Materials

Copper alloy generally costs more than brass alloy due to its higher copper content and limited availability of raw copper. Brass alloy, composed primarily of copper and zinc, offers a more affordable and widely available material option, benefiting from abundant zinc supplies. Manufacturers often prefer brass alloys for cost-effective production while maintaining desirable mechanical properties.

Alloy Selection Based on Performance Needs

Copper alloys offer superior electrical conductivity and corrosion resistance, making them ideal for high-performance electrical and marine applications. Brass alloys, composed primarily of copper and zinc, provide excellent machinability and strength, suited for decorative and mechanical components requiring moderate durability. Selecting between copper and brass alloys depends on specific performance criteria such as conductivity, corrosion resistance, machinability, and mechanical strength.

Environmental Impact and Recyclability

Copper alloys generally exhibit higher recyclability rates compared to brass alloys due to their simpler metal composition, which facilitates efficient separation and processing. Brass alloys, containing zinc and sometimes lead, pose greater environmental challenges during recycling because these elements require specialized treatment to prevent toxic emissions. Lifecycle analyses indicate that copper alloys generate a lower environmental footprint, with reduced energy consumption and greenhouse gas emissions during both production and recycling phases.

Copper Alloy vs Brass Alloy Infographic

materialdif.com

materialdif.com