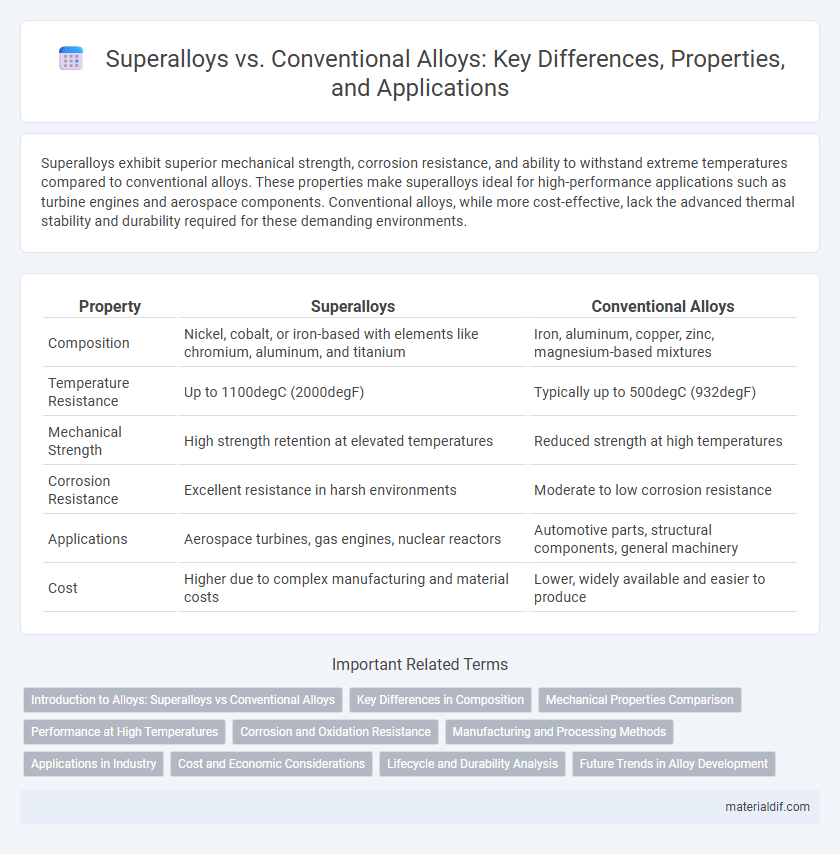

Superalloys exhibit superior mechanical strength, corrosion resistance, and ability to withstand extreme temperatures compared to conventional alloys. These properties make superalloys ideal for high-performance applications such as turbine engines and aerospace components. Conventional alloys, while more cost-effective, lack the advanced thermal stability and durability required for these demanding environments.

Table of Comparison

| Property | Superalloys | Conventional Alloys |

|---|---|---|

| Composition | Nickel, cobalt, or iron-based with elements like chromium, aluminum, and titanium | Iron, aluminum, copper, zinc, magnesium-based mixtures |

| Temperature Resistance | Up to 1100degC (2000degF) | Typically up to 500degC (932degF) |

| Mechanical Strength | High strength retention at elevated temperatures | Reduced strength at high temperatures |

| Corrosion Resistance | Excellent resistance in harsh environments | Moderate to low corrosion resistance |

| Applications | Aerospace turbines, gas engines, nuclear reactors | Automotive parts, structural components, general machinery |

| Cost | Higher due to complex manufacturing and material costs | Lower, widely available and easier to produce |

Introduction to Alloys: Superalloys vs Conventional Alloys

Superalloys exhibit exceptional high-temperature strength, corrosion resistance, and creep resistance, making them ideal for aerospace and power generation applications. Conventional alloys, primarily based on iron, aluminum, or copper, offer balanced mechanical properties but fall short under extreme thermal and oxidative environments. The unique composition of superalloys, often nickel or cobalt-based with elements like chromium, cobalt, and tungsten, enables superior performance compared to traditional alloys in demanding conditions.

Key Differences in Composition

Superalloys primarily consist of nickel, cobalt, or iron with high concentrations of chromium, aluminum, and titanium to enhance their resistance to heat and corrosion. Conventional alloys, such as steel or aluminum alloys, contain lower percentages of these elements and often emphasize mechanical strength and ductility over high-temperature stability. The unique compositional adjustments in superalloys enable superior performance in extreme environments compared to conventional alloys.

Mechanical Properties Comparison

Superalloys exhibit significantly higher mechanical strength and creep resistance than conventional alloys, especially at elevated temperatures above 700degC. Their advanced microstructure, often reinforced with elements like nickel, cobalt, and chromium, enhances fatigue resistance and maintains hardness under thermal stress. In contrast, conventional alloys typically suffer from accelerated degradation and mechanical failure under similar high-temperature and high-stress conditions.

Performance at High Temperatures

Superalloys maintain exceptional strength, oxidation resistance, and creep resistance at temperatures exceeding 900degC, outperforming conventional alloys that typically degrade above 600degC. Their complex microstructure, often reinforced by gamma prime precipitates, ensures superior mechanical stability and corrosion resistance in extreme environments such as jet engines and gas turbines. Conventional alloys lack these high-temperature phase reinforcements, limiting their applications where thermal stability and durability are critical.

Corrosion and Oxidation Resistance

Superalloys exhibit superior corrosion and oxidation resistance compared to conventional alloys due to their high concentrations of chromium, nickel, and aluminum, which form stable and protective oxide layers. These alloys maintain structural integrity at elevated temperatures, resisting aggressive environments found in aerospace and power generation applications. In contrast, conventional alloys typically suffer accelerated degradation under similar conditions, limiting their longevity and performance in high-stress, corrosive environments.

Manufacturing and Processing Methods

Superalloys undergo advanced manufacturing processes such as directional solidification and powder metallurgy to enhance high-temperature strength and corrosion resistance, while conventional alloys typically utilize casting and forging techniques. Precision control in superalloy processing minimizes defects and improves microstructural uniformity, essential for aerospace and turbine applications. Conventional alloys benefit from simpler, cost-effective methods but lack the specialized treatments that enable superalloys to perform under extreme conditions.

Applications in Industry

Superalloys exhibit exceptional mechanical strength, corrosion resistance, and stability at high temperatures, making them essential in aerospace, power generation, and chemical processing industries. Conventional alloys, while cost-effective and versatile, are commonly used in automotive, construction, and general manufacturing where extreme conditions are less critical. The superior thermal and oxidative resistance of superalloys enables their application in turbine engines and nuclear reactors, outperforming conventional alloys in demanding environments.

Cost and Economic Considerations

Superalloys, primarily composed of nickel, cobalt, and iron, exhibit superior high-temperature strength and corrosion resistance, justifying their higher initial cost in aerospace and power generation applications. Conventional alloys, often based on aluminum or steel, offer lower material and processing costs, making them economically viable for less demanding environments. The long-term performance and reduced maintenance requirements of superalloys can offset their higher upfront investment through improved component lifespan and reliability.

Lifecycle and Durability Analysis

Superalloys exhibit significantly enhanced lifecycle performance and durability compared to conventional alloys, maintaining mechanical integrity and resistance to oxidation and creep at extreme temperatures above 700degC. Their microstructural stability and advanced elemental composition, including high concentrations of nickel, cobalt, and chromium, enable prolonged service life in aerospace and power generation applications. Lifecycle analysis demonstrates that superalloys reduce maintenance frequency and downtime, resulting in lower total cost of ownership despite higher initial material costs.

Future Trends in Alloy Development

Future trends in alloy development emphasize enhanced performance under extreme conditions, driving innovation toward next-generation superalloys with improved high-temperature strength and oxidation resistance. Advanced manufacturing techniques such as additive manufacturing enable precise microstructural control, optimizing superalloy properties for aerospace and energy applications. Research focuses on developing novel compositions incorporating refractory metals and ceramic reinforcements to surpass the limitations of conventional alloys in durability and thermal stability.

Superalloys vs Conventional alloys Infographic

materialdif.com

materialdif.com