Nickel alloys offer superior corrosion resistance and high-temperature strength compared to stainless steel alloys, making them ideal for harsh chemical environments and extreme conditions. Stainless steel alloys provide excellent durability and cost-effectiveness for general applications, especially where moderate corrosion resistance and mechanical properties are sufficient. Choosing between nickel alloy and stainless steel alloy depends on the specific requirements of temperature, corrosion resistance, and budget constraints.

Table of Comparison

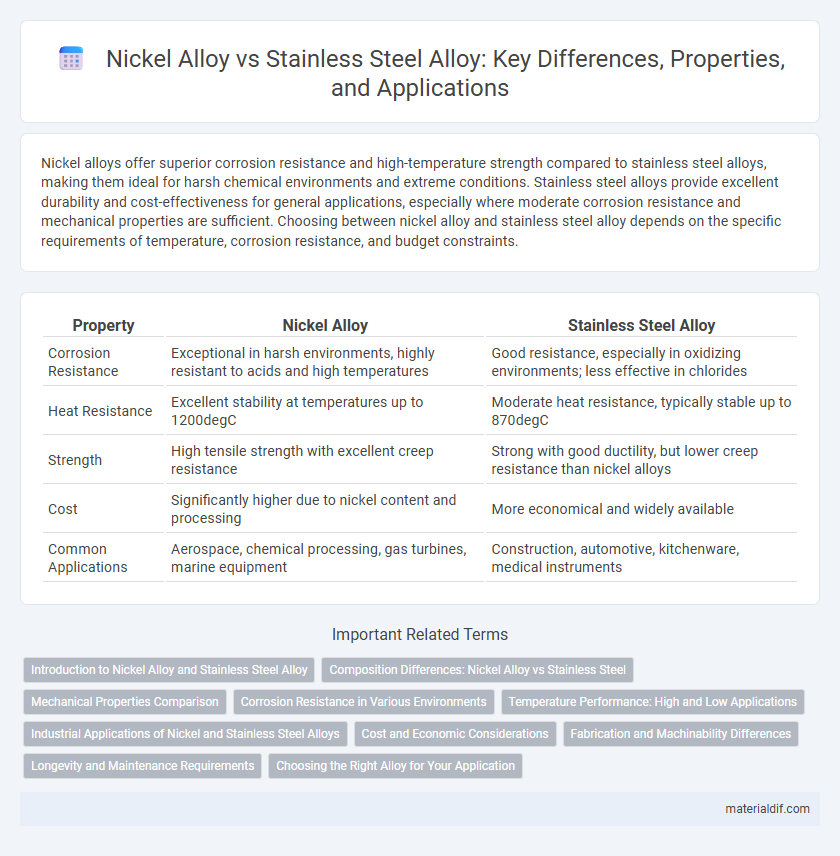

| Property | Nickel Alloy | Stainless Steel Alloy |

|---|---|---|

| Corrosion Resistance | Exceptional in harsh environments, highly resistant to acids and high temperatures | Good resistance, especially in oxidizing environments; less effective in chlorides |

| Heat Resistance | Excellent stability at temperatures up to 1200degC | Moderate heat resistance, typically stable up to 870degC |

| Strength | High tensile strength with excellent creep resistance | Strong with good ductility, but lower creep resistance than nickel alloys |

| Cost | Significantly higher due to nickel content and processing | More economical and widely available |

| Common Applications | Aerospace, chemical processing, gas turbines, marine equipment | Construction, automotive, kitchenware, medical instruments |

Introduction to Nickel Alloy and Stainless Steel Alloy

Nickel alloys are composed primarily of nickel combined with elements such as chromium, iron, and molybdenum, offering exceptional resistance to corrosion and high temperatures, making them ideal for harsh chemical environments and aerospace applications. Stainless steel alloys consist mainly of iron, chromium, and varying amounts of nickel and other elements, known for their strength, durability, and resistance to oxidation and staining in atmospheric conditions. Both nickel and stainless steel alloys serve critical roles in industrial sectors, with nickel alloys excelling in heat and corrosion resistance, while stainless steel alloys provide cost-effective solutions for structural integrity and corrosion protection.

Composition Differences: Nickel Alloy vs Stainless Steel

Nickel alloys primarily consist of high percentages of nickel combined with elements like chromium, iron, and molybdenum to enhance corrosion resistance and strength, while stainless steel alloys contain a lower nickel content with a higher proportion of iron and chromium, typically ranging from 10.5% to 30%. The increased nickel content in nickel alloys provides superior resistance to extreme environments such as high temperatures and acidic conditions compared to stainless steel. Chromium in stainless steel forms a passive oxide layer that prevents rust, but nickel alloys' specialized compositions offer enhanced durability for applications requiring exceptional mechanical performance and chemical resistance.

Mechanical Properties Comparison

Nickel alloys generally exhibit superior mechanical properties compared to stainless steel alloys, including higher tensile strength, excellent corrosion resistance, and outstanding creep resistance at elevated temperatures. Stainless steel alloys provide good mechanical strength and toughness but typically fall short in high-temperature performance and resistance to aggressive environments. The choice depends on application requirements, with nickel alloys preferred for extreme conditions and stainless steel alloys favored for cost-effective structural use.

Corrosion Resistance in Various Environments

Nickel alloys exhibit superior corrosion resistance compared to stainless steel alloys, especially in harsh environments such as acidic, saline, or high-temperature conditions. The high nickel content enhances their ability to resist pitting, crevice corrosion, and stress corrosion cracking, making them ideal for chemical processing and marine applications. Stainless steel alloys offer good corrosion resistance but are generally less effective in highly aggressive environments without additional alloying elements or protective coatings.

Temperature Performance: High and Low Applications

Nickel alloys exhibit superior temperature performance in extreme environments, maintaining mechanical strength and corrosion resistance at both high and low temperatures compared to stainless steel alloys. Stainless steel alloys tend to lose their toughness at cryogenic temperatures and weaken in prolonged high-heat exposure, whereas nickel alloys, such as Inconel and Monel, perform reliably in temperature ranges from -269degC up to 1200degC. This thermal stability makes nickel alloys the preferred choice for aerospace, chemical processing, and cryogenic applications requiring durable materials under severe thermal stress.

Industrial Applications of Nickel and Stainless Steel Alloys

Nickel alloys exhibit superior resistance to corrosion, high temperatures, and oxidation, making them ideal for chemical processing, aerospace, and power generation industries. Stainless steel alloys, valued for their strength, durability, and cost-effectiveness, are widely used in construction, automotive manufacturing, and food processing equipment. Both alloy types play critical roles in industrial applications where material performance under harsh environmental conditions is essential.

Cost and Economic Considerations

Nickel alloys generally exhibit higher upfront costs compared to stainless steel alloys due to the elevated price of nickel and specialized manufacturing processes. Stainless steel alloys offer greater economic advantages in large-scale projects because of lower raw material expenses and widespread availability. Total lifecycle costs should be evaluated, as nickel alloys provide superior corrosion resistance and durability, potentially reducing maintenance and replacement expenses over time.

Fabrication and Machinability Differences

Nickel alloys exhibit superior corrosion resistance and high-temperature strength compared to stainless steel alloys, which enhances their performance in demanding fabrication processes such as welding and forming. Machinability of nickel alloys is generally lower due to their toughness and work-hardening characteristics, requiring specialized tools and techniques, whereas stainless steel alloys offer better machinability but may suffer from work-hardening and heat generation during cutting. The choice between nickel and stainless steel alloys in manufacturing depends on balancing corrosion resistance needs against ease of machining and fabrication cost efficiency.

Longevity and Maintenance Requirements

Nickel alloys exhibit superior longevity compared to stainless steel alloys due to their enhanced corrosion resistance and high-temperature stability, making them ideal for harsh environments. Maintenance requirements for nickel alloys tend to be lower, as their resistance to oxidation and stress corrosion cracking reduces the need for frequent inspections and repairs. Stainless steel alloys require more regular upkeep to prevent rust and maintain structural integrity, especially in chemically aggressive or marine applications.

Choosing the Right Alloy for Your Application

Nickel alloys offer superior corrosion resistance and high-temperature strength compared to stainless steel alloys, making them ideal for harsh chemical environments and extreme thermal conditions. Stainless steel alloys provide excellent strength and affordability for general-purpose applications with moderate corrosion exposure. Selecting the right alloy depends on factors such as operating temperature, corrosion resistance requirements, mechanical stress, and budget constraints to ensure optimal performance and longevity.

Nickel Alloy vs Stainless Steel Alloy Infographic

materialdif.com

materialdif.com