Heat-treated alloys exhibit enhanced mechanical properties such as increased strength, hardness, and improved wear resistance compared to non-heat-treated alloys. The heat treatment process alters the microstructure, optimizing grain size and phase distribution for superior performance in demanding applications. Non-heat-treated alloys retain their original ductility and toughness but generally lack the elevated strength and hardness achieved through thermal processing.

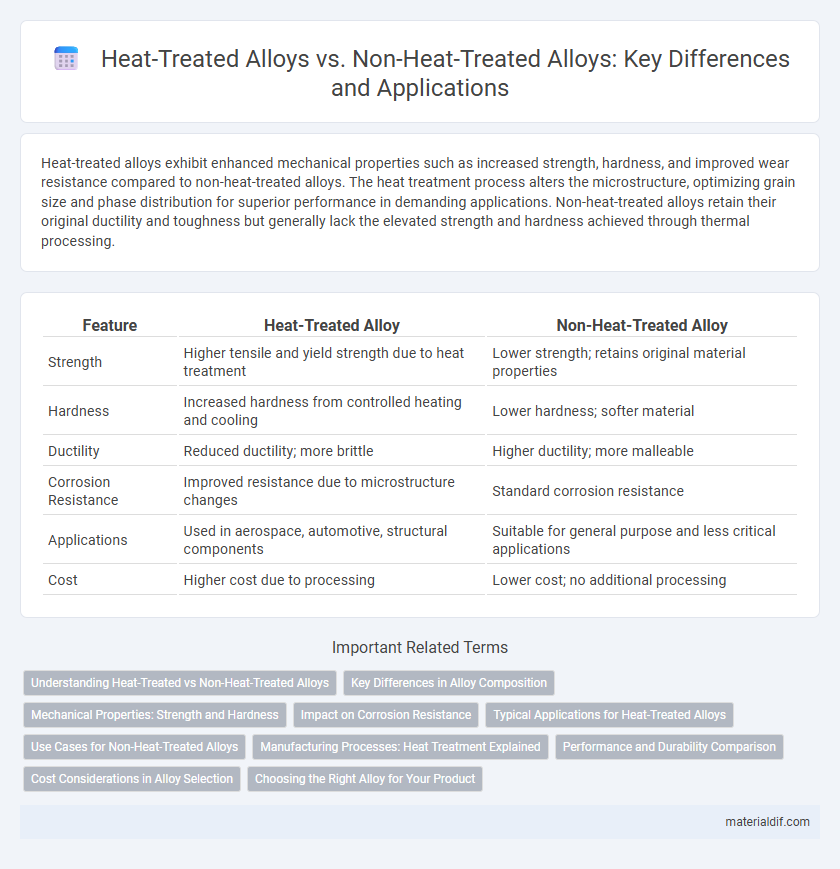

Table of Comparison

| Feature | Heat-Treated Alloy | Non-Heat-Treated Alloy |

|---|---|---|

| Strength | Higher tensile and yield strength due to heat treatment | Lower strength; retains original material properties |

| Hardness | Increased hardness from controlled heating and cooling | Lower hardness; softer material |

| Ductility | Reduced ductility; more brittle | Higher ductility; more malleable |

| Corrosion Resistance | Improved resistance due to microstructure changes | Standard corrosion resistance |

| Applications | Used in aerospace, automotive, structural components | Suitable for general purpose and less critical applications |

| Cost | Higher cost due to processing | Lower cost; no additional processing |

Understanding Heat-Treated vs Non-Heat-Treated Alloys

Heat-treated alloys undergo controlled heating and cooling processes to enhance their mechanical properties, such as increased strength, hardness, and improved wear resistance, compared to non-heat-treated alloys. Non-heat-treated alloys retain their original microstructure, often resulting in lower tensile strength and ductility. The choice between heat-treated and non-heat-treated alloys depends on the specific application requirements for performance and durability.

Key Differences in Alloy Composition

Heat-treated alloys undergo controlled thermal processes such as quenching and tempering, which alter the microstructure to enhance mechanical properties like strength, hardness, and toughness. Non-heat-treated alloys retain their original microstructure, resulting in lower strength and ductility compared to their heat-treated counterparts. Key compositional differences often involve the distribution and phase transformation of elements such as carbon, chromium, and nickel, which are optimized in heat-treated alloys to achieve superior performance in demanding applications.

Mechanical Properties: Strength and Hardness

Heat-treated alloys exhibit significantly higher strength and hardness compared to non-heat-treated alloys due to the formation of stronger microstructures like martensite or tempered phases. Non-heat-treated alloys typically maintain a softer, more ductile matrix, resulting in lower mechanical strength and reduced wear resistance. The enhancement in mechanical properties from heat treatment is critical for applications requiring durability and high load-bearing capacity.

Impact on Corrosion Resistance

Heat-treated alloys exhibit enhanced corrosion resistance due to the refined microstructure achieved through processes like quenching and tempering, which reduce internal stresses and improve passive film formation. In contrast, non-heat-treated alloys often display heterogeneous grain structures that can act as initiation sites for corrosion, leading to accelerated material degradation. The controlled heat treatment process optimizes alloy composition and phase distribution, significantly bolstering durability in corrosive environments.

Typical Applications for Heat-Treated Alloys

Heat-treated alloys are commonly used in aerospace components, automotive parts, and structural applications due to their enhanced strength, hardness, and fatigue resistance. These alloys undergo controlled heating and cooling processes to optimize mechanical properties essential for high-stress environments. Typical applications include turbine blades, engine parts, and high-performance fasteners where durability and reliability are critical.

Use Cases for Non-Heat-Treated Alloys

Non-heat-treated alloys are primarily utilized in applications requiring good corrosion resistance and moderate strength without the need for further mechanical enhancement, such as in marine environments and architectural structures. Their stability under ambient conditions makes them suitable for components like fasteners, fittings, and decorative elements, where heat treatment could compromise dimensional accuracy or surface finish. These alloys also find use in manufacturing processes involving welding or machining, where maintaining original grain structure and preventing distortion is critical.

Manufacturing Processes: Heat Treatment Explained

Heat-treated alloys undergo controlled thermal processes such as annealing, quenching, and tempering that alter their microstructure, improving mechanical properties like strength, hardness, and ductility. Non-heat-treated alloys maintain their original microstructure from casting or forming, often resulting in lower performance under stress or wear conditions. The heat treatment modifies dislocation density and phase distribution within the alloy, optimizing it for specific manufacturing applications requiring enhanced durability and resistance.

Performance and Durability Comparison

Heat-treated alloys exhibit enhanced mechanical properties such as increased strength, hardness, and wear resistance compared to non-heat-treated alloys due to controlled microstructural changes during thermal processing. Non-heat-treated alloys typically have lower tensile strength and are more prone to deformation and fatigue under high stress or extreme environmental conditions. The heat treatment process significantly improves durability and extends the service life of alloy components in demanding industrial applications.

Cost Considerations in Alloy Selection

Heat-treated alloys generally incur higher costs due to additional processing steps, including heating, controlled cooling, and specialized equipment, which enhance mechanical properties and durability. Non-heat-treated alloys offer lower initial costs but may require more frequent maintenance or replacement, leading to increased long-term expenses. Evaluating total lifecycle cost, including performance requirements and environmental conditions, is crucial for optimal alloy selection.

Choosing the Right Alloy for Your Product

Heat-treated alloys exhibit enhanced mechanical properties such as increased strength, hardness, and wear resistance compared to non-heat-treated alloys, making them ideal for high-stress applications like aerospace and automotive components. Non-heat-treated alloys maintain better ductility and corrosion resistance, suitable for products requiring flexibility and exposure to harsh environments. Selecting the right alloy depends on the balance between desired strength, durability, and environmental factors specific to the product's end use.

Heat-Treated Alloy vs Non-Heat-Treated Alloy Infographic

materialdif.com

materialdif.com