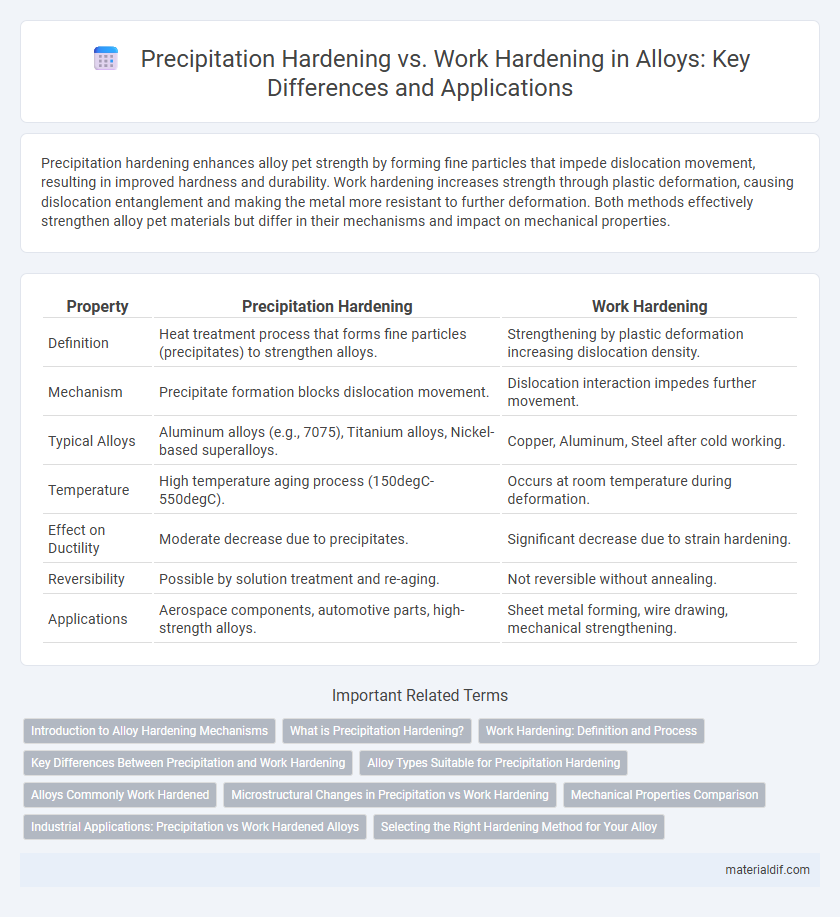

Precipitation hardening enhances alloy pet strength by forming fine particles that impede dislocation movement, resulting in improved hardness and durability. Work hardening increases strength through plastic deformation, causing dislocation entanglement and making the metal more resistant to further deformation. Both methods effectively strengthen alloy pet materials but differ in their mechanisms and impact on mechanical properties.

Table of Comparison

| Property | Precipitation Hardening | Work Hardening |

|---|---|---|

| Definition | Heat treatment process that forms fine particles (precipitates) to strengthen alloys. | Strengthening by plastic deformation increasing dislocation density. |

| Mechanism | Precipitate formation blocks dislocation movement. | Dislocation interaction impedes further movement. |

| Typical Alloys | Aluminum alloys (e.g., 7075), Titanium alloys, Nickel-based superalloys. | Copper, Aluminum, Steel after cold working. |

| Temperature | High temperature aging process (150degC-550degC). | Occurs at room temperature during deformation. |

| Effect on Ductility | Moderate decrease due to precipitates. | Significant decrease due to strain hardening. |

| Reversibility | Possible by solution treatment and re-aging. | Not reversible without annealing. |

| Applications | Aerospace components, automotive parts, high-strength alloys. | Sheet metal forming, wire drawing, mechanical strengthening. |

Introduction to Alloy Hardening Mechanisms

Precipitation hardening enhances alloy strength by forming fine, dispersed particles that impede dislocation motion within the metal matrix. Work hardening increases hardness through plastic deformation, which generates dislocations that intersect and restrict further movement. Both mechanisms improve mechanical properties but operate via distinct microstructural changes critical in metallurgy and materials engineering.

What is Precipitation Hardening?

Precipitation hardening is a heat treatment process used in alloys to increase strength and hardness by forming fine particles, or precipitates, within the metal matrix. These precipitates hinder dislocation movement, enhancing the material's mechanical properties without significantly reducing ductility. This method is commonly applied in aluminum, titanium, and nickel-based alloys to improve performance in aerospace and automotive industries.

Work Hardening: Definition and Process

Work hardening, also known as strain hardening, is the process where a metal becomes stronger and harder due to plastic deformation at temperatures below its recrystallization point. During deformation, dislocation density within the alloy increases, which impedes further dislocation movement and enhances strength. This mechanism is widely used in alloys like aluminum and copper to improve mechanical properties without heat treatment.

Key Differences Between Precipitation and Work Hardening

Precipitation hardening involves the formation of fine particles within the metal matrix, which hinder dislocation movement and significantly increase alloy strength, particularly in aluminum and titanium alloys. Work hardening, also known as strain hardening, occurs through plastic deformation that increases dislocation density, thereby enhancing strength without altering the alloy's chemical composition. Key differences include that precipitation hardening requires heat treatment for particle formation, while work hardening relies solely on mechanical deformation, making their applications and effects on microstructure distinct.

Alloy Types Suitable for Precipitation Hardening

Precipitation hardening is particularly effective in age-hardenable alloys such as aluminum-copper (2xxx series), nickel-based superalloys, and some stainless steels like 17-4 PH. These alloys undergo controlled heat treatment to form fine precipitates that obstruct dislocation movement, significantly enhancing strength and hardness. Work hardening, by contrast, is more applicable to metals like pure copper and austenitic stainless steels, which strengthen through plastic deformation rather than precipitation.

Alloys Commonly Work Hardened

Alloys commonly work hardened include copper-based alloys such as brass and bronze, as well as austenitic stainless steels due to their face-centered cubic (FCC) crystal structure, which allows extensive plastic deformation. Work hardening increases dislocation density, improving strength and hardness without altering the alloy's phase composition. In contrast, precipitation hardening involves the formation of fine particles within the matrix to obstruct dislocation motion, effective in aluminum and nickel-based alloys like 7075 aluminum and Inconel 718.

Microstructural Changes in Precipitation vs Work Hardening

Precipitation hardening involves the formation of fine, dispersed precipitates within the alloy matrix that hinder dislocation movement, significantly enhancing strength through controlled thermal treatment. Work hardening, or strain hardening, produces a high density of dislocations within the crystal lattice, increasing internal stress and impeding further dislocation motion without altering the alloy's phase composition. The microstructural changes in precipitation hardening are characterized by secondary phase particles, while work hardening fundamentally changes the dislocation structure and defect density.

Mechanical Properties Comparison

Precipitation hardening significantly improves tensile strength and yield strength by forming fine, uniformly distributed precipitates that hinder dislocation movement. Work hardening increases hardness and strength through plastic deformation, creating dislocation tangles that obstruct slip systems but may reduce ductility. Compared to work hardening, precipitation hardening offers better balance of high strength and toughness, making it ideal for high-performance alloys requiring enhanced mechanical properties.

Industrial Applications: Precipitation vs Work Hardened Alloys

Precipitation-hardened alloys exhibit superior strength and corrosion resistance, making them ideal for aerospace and automotive components requiring high fatigue life and dimensional stability. Work-hardened alloys provide enhanced surface hardness and wear resistance, commonly used in manufacturing tools and structural parts subjected to mechanical stress. Industrial applications favor precipitation hardening for critical load-bearing parts, while work hardening suits components needing localized strengthening with simpler processing.

Selecting the Right Hardening Method for Your Alloy

Selecting the right hardening method for your alloy depends on the desired mechanical properties and alloy composition. Precipitation hardening is ideal for alloys like aluminum or titanium, offering enhanced strength through controlled heat treatment that forms fine precipitates. Work hardening suits alloys such as copper or stainless steel, improving hardness by plastic deformation without altering the alloy's chemical structure.

Precipitation Hardening vs Work Hardening Infographic

materialdif.com

materialdif.com