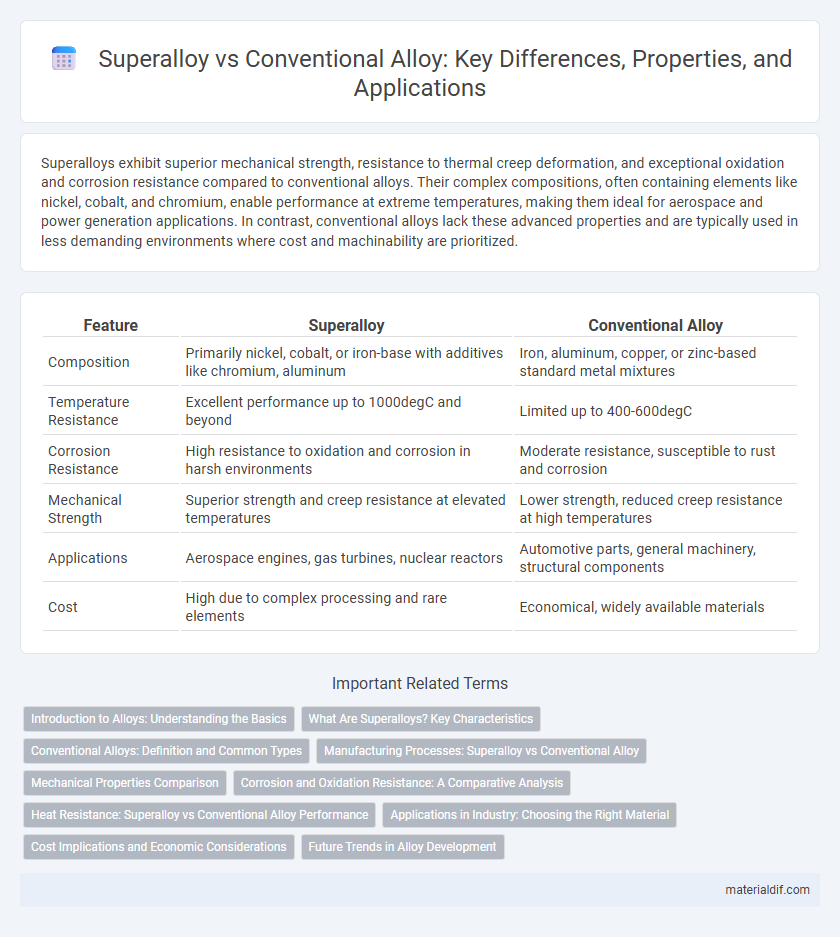

Superalloys exhibit superior mechanical strength, resistance to thermal creep deformation, and exceptional oxidation and corrosion resistance compared to conventional alloys. Their complex compositions, often containing elements like nickel, cobalt, and chromium, enable performance at extreme temperatures, making them ideal for aerospace and power generation applications. In contrast, conventional alloys lack these advanced properties and are typically used in less demanding environments where cost and machinability are prioritized.

Table of Comparison

| Feature | Superalloy | Conventional Alloy |

|---|---|---|

| Composition | Primarily nickel, cobalt, or iron-base with additives like chromium, aluminum | Iron, aluminum, copper, or zinc-based standard metal mixtures |

| Temperature Resistance | Excellent performance up to 1000degC and beyond | Limited up to 400-600degC |

| Corrosion Resistance | High resistance to oxidation and corrosion in harsh environments | Moderate resistance, susceptible to rust and corrosion |

| Mechanical Strength | Superior strength and creep resistance at elevated temperatures | Lower strength, reduced creep resistance at high temperatures |

| Applications | Aerospace engines, gas turbines, nuclear reactors | Automotive parts, general machinery, structural components |

| Cost | High due to complex processing and rare elements | Economical, widely available materials |

Introduction to Alloys: Understanding the Basics

Superalloys are advanced alloys engineered for exceptional strength, oxidation resistance, and stability at high temperatures, making them essential in aerospace and power generation industries. Conventional alloys typically combine two or more metals to enhance mechanical properties and corrosion resistance but lack the extreme performance capabilities of superalloys. Understanding the microstructure and composition differences between superalloys and conventional alloys is crucial for selecting appropriate materials in demanding engineering applications.

What Are Superalloys? Key Characteristics

Superalloys are high-performance alloys primarily composed of nickel, cobalt, or iron designed to maintain strength, corrosion resistance, and stability at extreme temperatures above 700degC. Key characteristics include exceptional oxidation and creep resistance, superior mechanical strength, and excellent fatigue resistance, making them essential in aerospace, gas turbines, and nuclear reactors. Unlike conventional alloys, superalloys feature complex microstructures often reinforced with gamma prime (g') precipitates and solid solution strengthening elements to enhance durability under harsh conditions.

Conventional Alloys: Definition and Common Types

Conventional alloys are mixtures of two or more metals or a metal with non-metal elements designed to enhance mechanical properties like strength, ductility, and corrosion resistance. Common types include steel (iron-carbon alloy), brass (copper-zinc alloy), and bronze (copper-tin alloy), each tailored for specific industrial applications such as construction, plumbing, and machinery components. These alloys typically operate effectively at moderate temperatures compared to superalloys, which are engineered for extreme environments like aerospace or power generation.

Manufacturing Processes: Superalloy vs Conventional Alloy

Superalloys require advanced manufacturing processes such as vacuum induction melting, directional solidification, and powder metallurgy to achieve superior high-temperature strength and corrosion resistance. Conventional alloys are typically produced using standard casting, forging, and rolling methods, which offer cost-effective fabrication but with lower performance under extreme conditions. Precision manufacturing techniques for superalloys ensure microstructural control and minimize defects, critical for aerospace and power generation applications.

Mechanical Properties Comparison

Superalloys exhibit superior mechanical properties compared to conventional alloys, including higher tensile strength, improved creep resistance, and enhanced fatigue life at elevated temperatures. Their microstructure, often reinforced by gamma-prime precipitates, provides exceptional stability under extreme thermal and mechanical stress. Conventional alloys typically lack this high-temperature performance, limiting their application in aerospace and power generation industries where durability and strength are critical.

Corrosion and Oxidation Resistance: A Comparative Analysis

Superalloys exhibit superior corrosion and oxidation resistance compared to conventional alloys due to their high concentrations of elements like chromium, aluminum, and cobalt, which form stable oxide layers that protect the underlying metal. Conventional alloys often lack these protective oxide scales and thus experience accelerated degradation in harsh environments, reducing their lifespan. Advanced superalloys are especially critical in aerospace and power generation industries, where materials must endure extreme temperatures and oxidative stress without compromising structural integrity.

Heat Resistance: Superalloy vs Conventional Alloy Performance

Superalloys exhibit exceptional heat resistance compared to conventional alloys, maintaining mechanical strength and oxidation resistance at temperatures exceeding 1000degC. Conventional alloys typically fail under extreme thermal stress due to lower melting points and reduced creep resistance. The superior microstructure and alloying elements in superalloys enable prolonged durability in high-temperature applications like jet engines and gas turbines.

Applications in Industry: Choosing the Right Material

Superalloys excel in high-temperature and high-stress environments, making them ideal for aerospace gas turbines, jet engines, and nuclear reactors where durability and resistance to thermal creep are critical. Conventional alloys find extensive use in automotive components, structural frameworks, and general manufacturing due to their cost-effectiveness and adequate performance under moderate conditions. Selecting between superalloy and conventional alloy depends on operational temperature, mechanical stress, and economic considerations specific to the industrial application.

Cost Implications and Economic Considerations

Superalloys exhibit superior high-temperature strength and corrosion resistance compared to conventional alloys, resulting in higher upfront material and manufacturing costs but offering extended lifespan and reduced maintenance expenses. The elevated initial investment in superalloys is often offset by improved performance in critical applications such as aerospace and power generation, where long-term reliability and efficiency are paramount. Economic considerations include lifecycle cost analysis, emphasizing total cost of ownership rather than just material price.

Future Trends in Alloy Development

Future trends in alloy development emphasize the enhancement of superalloys through advanced additive manufacturing techniques and nanostructuring to improve high-temperature strength and corrosion resistance. Integration of machine learning and computational materials science accelerates the discovery of novel superalloy compositions with optimized mechanical properties and reduced weight. Sustainable alloy processing methods and recycling innovations aim to minimize environmental impact while meeting the demanding performance requirements of aerospace and energy industries.

Superalloy vs Conventional Alloy Infographic

materialdif.com

materialdif.com