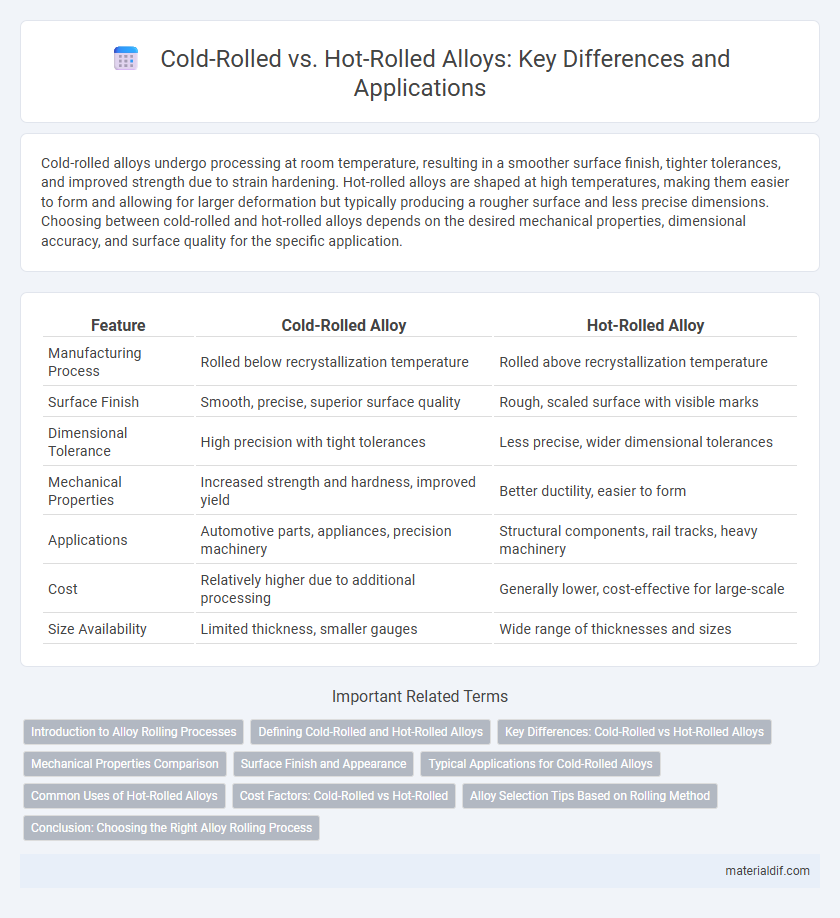

Cold-rolled alloys undergo processing at room temperature, resulting in a smoother surface finish, tighter tolerances, and improved strength due to strain hardening. Hot-rolled alloys are shaped at high temperatures, making them easier to form and allowing for larger deformation but typically producing a rougher surface and less precise dimensions. Choosing between cold-rolled and hot-rolled alloys depends on the desired mechanical properties, dimensional accuracy, and surface quality for the specific application.

Table of Comparison

| Feature | Cold-Rolled Alloy | Hot-Rolled Alloy |

|---|---|---|

| Manufacturing Process | Rolled below recrystallization temperature | Rolled above recrystallization temperature |

| Surface Finish | Smooth, precise, superior surface quality | Rough, scaled surface with visible marks |

| Dimensional Tolerance | High precision with tight tolerances | Less precise, wider dimensional tolerances |

| Mechanical Properties | Increased strength and hardness, improved yield | Better ductility, easier to form |

| Applications | Automotive parts, appliances, precision machinery | Structural components, rail tracks, heavy machinery |

| Cost | Relatively higher due to additional processing | Generally lower, cost-effective for large-scale |

| Size Availability | Limited thickness, smaller gauges | Wide range of thicknesses and sizes |

Introduction to Alloy Rolling Processes

Cold-rolled and hot-rolled are two fundamental alloy rolling processes used to shape metals by passing them through rollers under controlled temperatures. Hot-rolling occurs above the metal's recrystallization temperature, enabling easier deformation and improved ductility, while cold-rolling happens below this temperature, resulting in higher strength and better surface finish due to strain hardening. Each process impacts alloy properties differently, making the choice critical for applications requiring specific mechanical characteristics and surface qualities.

Defining Cold-Rolled and Hot-Rolled Alloys

Cold-rolled alloys undergo deformation at room temperature, resulting in a smoother surface finish and tighter dimensional tolerances, ideal for applications requiring precision and enhanced mechanical properties. Hot-rolled alloys are processed above their recrystallization temperature, allowing easier shaping and forming but producing rougher surfaces and looser tolerances. The choice between cold-rolled and hot-rolled alloys depends on the required strength, surface quality, and dimensional accuracy for specific industrial uses.

Key Differences: Cold-Rolled vs Hot-Rolled Alloys

Cold-rolled alloys undergo deformation at room temperature, resulting in a smoother surface finish and higher dimensional accuracy, while hot-rolled alloys are processed above recrystallization temperature, allowing easier shaping but with a rougher texture. The microstructure of cold-rolled alloys exhibits increased strength and hardness due to strain hardening, whereas hot-rolled alloys maintain better ductility and are less prone to residual stress. Key industrial applications differentiate based on these properties: cold-rolled alloys suit precision components, and hot-rolled alloys are preferred for structural steelwork.

Mechanical Properties Comparison

Cold-rolled alloys exhibit higher tensile strength and improved surface finish compared to hot-rolled alloys due to work hardening during the rolling process. Hot-rolled alloys generally offer better ductility and impact resistance because the metal undergoes slower cooling rates, resulting in coarser grain structures. The mechanical properties of cold-rolled alloys make them ideal for applications requiring precision and strength, whereas hot-rolled alloys suit components needing toughness and formability.

Surface Finish and Appearance

Cold-rolled alloys exhibit a smooth, shiny surface finish due to the precise rolling process at lower temperatures, which enhances dimensional accuracy and aesthetic appeal. Hot-rolled alloys typically have a rougher, matte surface with scale and oxidation marks caused by cooling at high temperatures. The choice between cold-rolled and hot-rolled alloys depends on the desired surface quality and visual requirements for specific applications.

Typical Applications for Cold-Rolled Alloys

Cold-rolled alloys are predominantly used in applications requiring precise dimensions and smooth surface finishes, such as automotive panels, appliances, and metal furniture. Their enhanced strength and tighter tolerances make them ideal for precision engineering components, electrical enclosures, and structural parts in aerospace industries. These alloys are favored where aesthetic quality and surface treatment compatibility are critical, including consumer electronics and architectural elements.

Common Uses of Hot-Rolled Alloys

Hot-rolled alloys are commonly used in construction and heavy equipment manufacturing due to their enhanced ductility and toughness, which allow them to withstand structural stress and harsh environmental conditions. They are preferred for applications like rail tracks, shipbuilding, and large steel beams where dimensional accuracy is less critical but strength and formability are essential. The hot-rolling process also makes these alloys suitable for components requiring significant machining or welding.

Cost Factors: Cold-Rolled vs Hot-Rolled

Cold-rolled steel incurs higher production costs due to additional processing steps like annealing and surface finishing, resulting in a more refined surface and tighter tolerances. Hot-rolled steel benefits from a simpler manufacturing process, allowing for lower initial costs but typically features a rougher surface and less precise dimensions. The choice between cold-rolled and hot-rolled steel often depends on balancing budget constraints with required material properties and surface quality.

Alloy Selection Tips Based on Rolling Method

Cold-rolled alloys exhibit enhanced surface finish and tighter dimensional tolerances, making them ideal for applications requiring precision and aesthetic appeal, such as automotive panels and appliances. Hot-rolled alloys, with their improved ductility and lower production costs, are better suited for structural components and heavy-duty fabrication where strength outweighs surface quality. When selecting alloys, consider cold-rolled options for high-strength, wear-resistant applications and hot-rolled choices for large-scale construction projects that demand toughness and formability.

Conclusion: Choosing the Right Alloy Rolling Process

Cold-rolled alloys offer superior surface finish, tighter tolerances, and enhanced mechanical properties, making them ideal for precision applications such as automotive and aerospace components. Hot-rolled alloys provide better ductility, larger section sizes, and cost-effectiveness, suited for structural and industrial uses requiring less stringent surface quality. Selecting the right rolling process depends on balancing application demands like strength, surface finish, production speed, and budget constraints to achieve optimal alloy performance.

Cold-rolled vs Hot-rolled Infographic

materialdif.com

materialdif.com