Hardening increases the strength and hardness of an alloy by inducing a controlled increase in dislocation density, making the metal more resistant to deformation. Annealing, on the other hand, reduces internal stresses and softens the alloy by allowing recrystallization and grain growth, which enhances ductility and relieves brittleness. Understanding the balance between hardening and annealing processes is essential for optimizing the mechanical properties of alloys for specific applications.

Table of Comparison

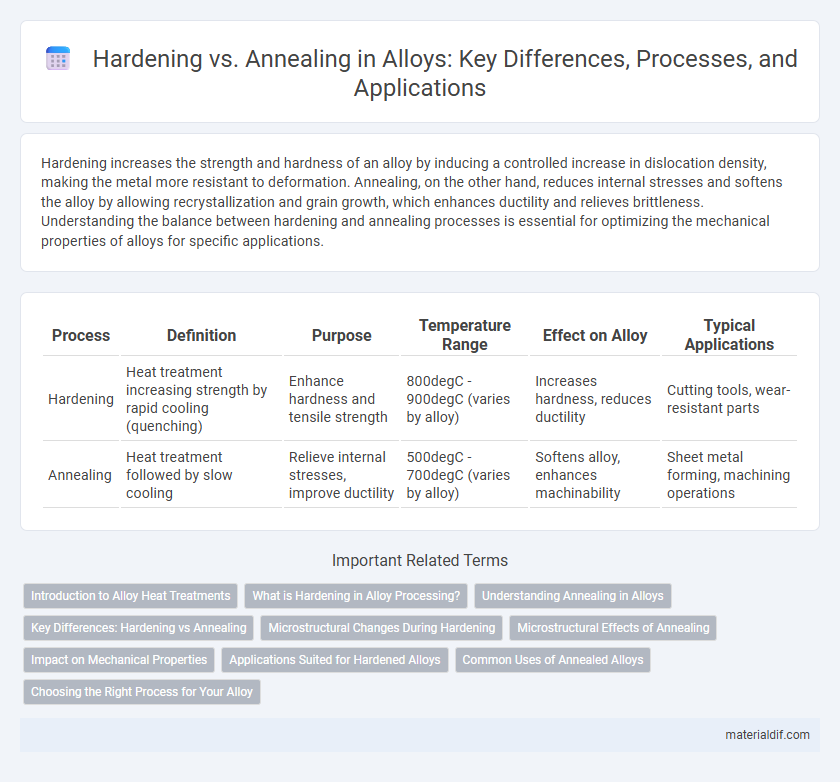

| Process | Definition | Purpose | Temperature Range | Effect on Alloy | Typical Applications |

|---|---|---|---|---|---|

| Hardening | Heat treatment increasing strength by rapid cooling (quenching) | Enhance hardness and tensile strength | 800degC - 900degC (varies by alloy) | Increases hardness, reduces ductility | Cutting tools, wear-resistant parts |

| Annealing | Heat treatment followed by slow cooling | Relieve internal stresses, improve ductility | 500degC - 700degC (varies by alloy) | Softens alloy, enhances machinability | Sheet metal forming, machining operations |

Introduction to Alloy Heat Treatments

Alloy heat treatments, such as hardening and annealing, significantly influence the mechanical properties and microstructure of metals. Hardening typically involves heating the alloy to a high temperature followed by rapid cooling, which increases strength and hardness by forming martensitic structures. Annealing, on the other hand, involves heating the alloy to a specific temperature and cooling slowly, which reduces internal stresses, improves ductility, and refines the grain structure.

What is Hardening in Alloy Processing?

Hardening in alloy processing involves increasing the strength and hardness of the metal by altering its microstructure through heat treatment or mechanical deformation. This process typically includes quenching, where the alloy is rapidly cooled to trap carbon atoms, resulting in a harder but more brittle material. Hardening improves wear resistance and durability, essential for applications demanding high strength and toughness.

Understanding Annealing in Alloys

Annealing in alloys involves heating the metal to a specific temperature and then cooling it slowly to reduce internal stresses and increase ductility. This process refines the microstructure by promoting the formation of larger, more uniform grains, enhancing the alloy's toughness and machinability. Compared to hardening, which increases strength and hardness through rapid cooling or cold working, annealing prioritizes softness and improved workability.

Key Differences: Hardening vs Annealing

Hardening increases an alloy's strength and hardness by rapidly cooling it from a high temperature, often using quenching methods to create a more rigid microstructure. Annealing, in contrast, involves heating the alloy to a specific temperature followed by slow cooling, which softens the material, improves ductility, and reduces internal stresses. These processes serve opposite purposes: hardening strengthens but reduces ductility, while annealing enhances malleability and repairs structural defects in the metal.

Microstructural Changes During Hardening

During hardening, alloys undergo microstructural changes such as the formation of martensite or bainite, which significantly increase hardness and strength by creating a distorted lattice structure that impedes dislocation movement. The rapid cooling or quenching process traps carbon atoms in a supersaturated solid solution, resulting in a strained and highly stressed microstructure. These transformations contrast with annealing, where slow cooling promotes the formation of equilibrium phases like pearlite, softening the alloy and enhancing ductility.

Microstructural Effects of Annealing

Annealing refines the microstructure of alloys by reducing dislocation density and promoting grain growth, which enhances ductility and reduces internal stresses. This process transforms the metal's crystalline structure, resulting in a more uniform grain size that improves mechanical properties and machinability. In contrast to hardening, annealing reverses prior cold work effects, facilitating recrystallization and eliminating defects within the alloy's microstructure.

Impact on Mechanical Properties

Hardening increases an alloy's strength and hardness by introducing dislocations and refining its microstructure, enhancing resistance to deformation. Annealing reduces internal stresses and refines grain structure, improving ductility and toughness but lowering hardness and strength. These heat treatment processes allow tailored mechanical properties to meet specific performance requirements in engineering applications.

Applications Suited for Hardened Alloys

Hardened alloys offer exceptional wear resistance and strength, making them ideal for high-stress applications such as automotive components, aerospace parts, and cutting tools. Their enhanced hardness improves durability in environments subject to repetitive mechanical loads and abrasion. These properties enable hardened alloys to perform reliably in manufacturing machinery and structural frameworks where long-term performance and fatigue resistance are critical.

Common Uses of Annealed Alloys

Annealed alloys are commonly used in applications requiring enhanced ductility and improved machinability, such as in automotive components, electrical wiring, and metal forming processes. The annealing process reduces internal stresses and softens the metal, making it easier to shape and work with. These alloys are vital in manufacturing environments where precision and flexibility in metal deformation are essential.

Choosing the Right Process for Your Alloy

Selecting the appropriate heat treatment process for your alloy depends on the desired mechanical properties and application requirements. Hardening increases strength and wear resistance by creating a martensitic structure, whereas annealing enhances ductility and relieves internal stresses through controlled heating and cooling cycles. Understanding the alloy composition, such as carbon content in steel or aluminum-titanium ratios, ensures the optimal balance between toughness and malleability for specific industrial uses.

Hardening vs Annealing Infographic

materialdif.com

materialdif.com