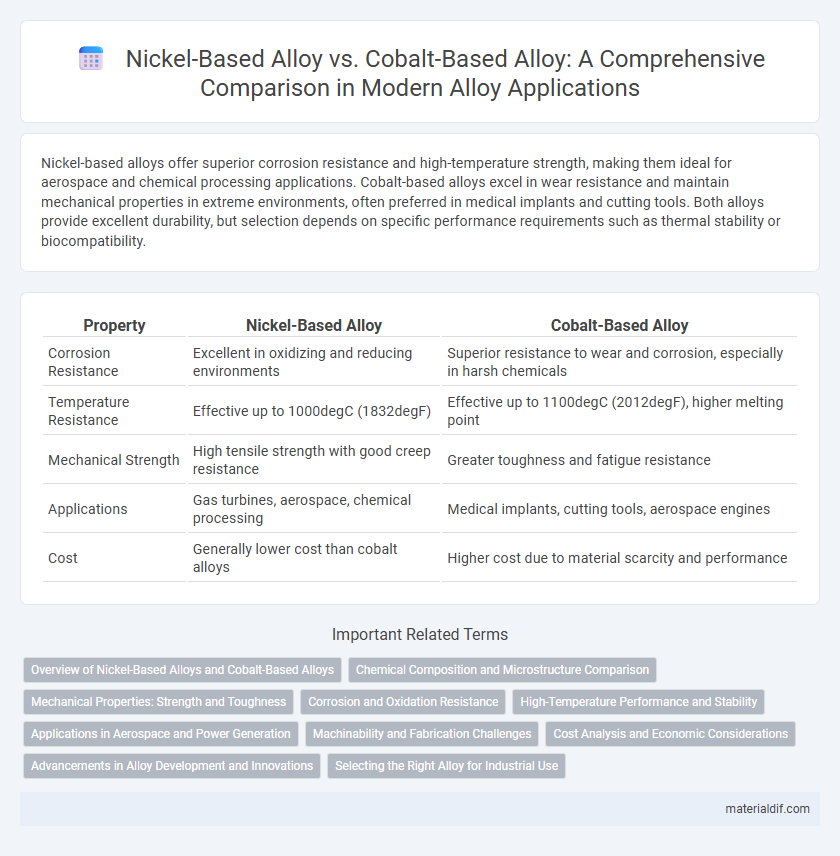

Nickel-based alloys offer superior corrosion resistance and high-temperature strength, making them ideal for aerospace and chemical processing applications. Cobalt-based alloys excel in wear resistance and maintain mechanical properties in extreme environments, often preferred in medical implants and cutting tools. Both alloys provide excellent durability, but selection depends on specific performance requirements such as thermal stability or biocompatibility.

Table of Comparison

| Property | Nickel-Based Alloy | Cobalt-Based Alloy |

|---|---|---|

| Corrosion Resistance | Excellent in oxidizing and reducing environments | Superior resistance to wear and corrosion, especially in harsh chemicals |

| Temperature Resistance | Effective up to 1000degC (1832degF) | Effective up to 1100degC (2012degF), higher melting point |

| Mechanical Strength | High tensile strength with good creep resistance | Greater toughness and fatigue resistance |

| Applications | Gas turbines, aerospace, chemical processing | Medical implants, cutting tools, aerospace engines |

| Cost | Generally lower cost than cobalt alloys | Higher cost due to material scarcity and performance |

Overview of Nickel-Based Alloys and Cobalt-Based Alloys

Nickel-based alloys exhibit exceptional corrosion resistance, high strength, and thermal stability, making them ideal for aerospace, chemical processing, and power generation industries. Cobalt-based alloys offer superior wear resistance, excellent strength at elevated temperatures, and exceptional biocompatibility, commonly used in medical implants and high-temperature turbine components. Both alloys maintain robust mechanical properties under extreme environmental conditions but differ primarily in specific applications due to their unique elemental compositions and performance characteristics.

Chemical Composition and Microstructure Comparison

Nickel-based alloys typically contain higher percentages of chromium (14-22%), molybdenum (8-10%), and iron, which enhance corrosion resistance and high-temperature strength, whereas cobalt-based alloys have a chromium content around 20-30% and significant amounts of tungsten and carbon that improve wear resistance and hardness. The microstructure of nickel-based alloys often features a gamma (g) matrix with gamma prime (g') precipitates providing excellent creep resistance, while cobalt-based alloys exhibit a face-centered cubic matrix with complex carbide and intermetallic precipitates that contribute to superior thermal stability and mechanical strength. Variations in chemical composition directly influence the phase stability and precipitation behavior, which define the performance characteristics in extreme environments.

Mechanical Properties: Strength and Toughness

Nickel-based alloys exhibit superior tensile strength and excellent creep resistance at high temperatures, making them ideal for demanding mechanical applications. Cobalt-based alloys offer exceptional toughness and impact resistance, particularly under extreme thermal cycling and corrosive environments. Both alloys maintain high strength-to-weight ratios, but nickel-based alloys generally outperform cobalt alloys in fatigue resistance and long-term mechanical stability.

Corrosion and Oxidation Resistance

Nickel-based alloys exhibit superior corrosion resistance due to their ability to form a stable oxide layer that protects against acidic and chloride environments. Cobalt-based alloys offer excellent oxidation resistance at elevated temperatures, making them ideal for high-heat applications in aggressive atmospheres. Both alloy types maintain structural integrity, but nickel alloys generally outperform in chemical corrosion while cobalt alloys excel in thermal oxidation stability.

High-Temperature Performance and Stability

Nickel-based alloys exhibit exceptional high-temperature performance due to their superior oxidation resistance and mechanical strength at elevated temperatures, making them ideal for aerospace and power generation applications. Cobalt-based alloys offer enhanced thermal stability and corrosion resistance in extreme environments, particularly in chemical processing and medical devices. The choice between nickel-based and cobalt-based alloys depends on specific operational conditions, with nickel alloys favored for higher temperature tolerance and cobalt alloys for improved chemical stability.

Applications in Aerospace and Power Generation

Nickel-based alloys are extensively used in aerospace for turbine blades and jet engines due to their exceptional high-temperature strength and oxidation resistance. Cobalt-based alloys find application in power generation, particularly in gas turbines, where their superior hot corrosion resistance and thermal fatigue properties enhance operational durability. Both alloys contribute to improved efficiency and performance in extreme environments, with nickel alloys favored for structural components and cobalt alloys for wear-resistant parts.

Machinability and Fabrication Challenges

Nickel-based alloys generally offer superior machinability compared to cobalt-based alloys due to their lower hardness and better thermal conductivity, facilitating easier cutting and reduced tool wear. Cobalt-based alloys, known for their exceptional strength and corrosion resistance at high temperatures, present significant fabrication challenges such as rapid tool wear, work hardening, and poor thermal conductivity, which complicate machining operations. These differences necessitate specialized tooling and optimized machining parameters when working with cobalt-based alloys to achieve efficiency and precision in fabrication processes.

Cost Analysis and Economic Considerations

Nickel-based alloys generally offer a lower initial material cost compared to cobalt-based alloys, making them more economical for large-scale manufacturing and applications requiring cost efficiency. Cobalt-based alloys, while more expensive, provide superior wear resistance and high-temperature performance, which can reduce long-term maintenance and replacement expenses in critical environments. Economic considerations balance upfront pricing with lifecycle costs, where nickel alloys suit budget-sensitive projects and cobalt alloys justify their premium through durability and reduced downtime.

Advancements in Alloy Development and Innovations

Nickel-based alloys exhibit superior corrosion resistance and high-temperature strength, making them essential for aerospace and power generation industries. Cobalt-based alloys offer enhanced wear resistance and magnetic properties, driving innovation in medical implants and cutting tools. Recent advancements focus on microstructural engineering and additive manufacturing techniques to optimize performance and extend the service life of both alloy types.

Selecting the Right Alloy for Industrial Use

Nickel-based alloys offer superior corrosion resistance and high-temperature strength, making them ideal for chemical processing and aerospace applications where durability under extreme conditions is critical. Cobalt-based alloys excel in wear resistance and oxidation stability, particularly suited for cutting tools and turbine blades exposed to abrasive environments. Selecting the right alloy depends on balancing factors like thermal stability, mechanical strength, and environmental exposure to optimize performance and longevity in industrial use.

Nickel-based alloy vs Cobalt-based alloy Infographic

materialdif.com

materialdif.com