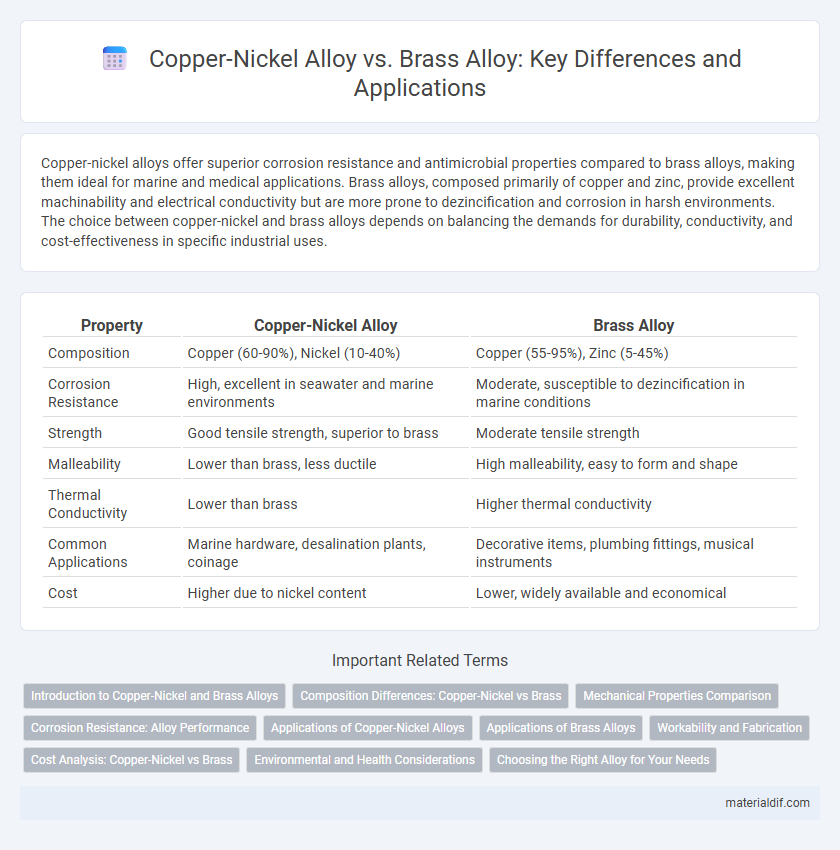

Copper-nickel alloys offer superior corrosion resistance and antimicrobial properties compared to brass alloys, making them ideal for marine and medical applications. Brass alloys, composed primarily of copper and zinc, provide excellent machinability and electrical conductivity but are more prone to dezincification and corrosion in harsh environments. The choice between copper-nickel and brass alloys depends on balancing the demands for durability, conductivity, and cost-effectiveness in specific industrial uses.

Table of Comparison

| Property | Copper-Nickel Alloy | Brass Alloy |

|---|---|---|

| Composition | Copper (60-90%), Nickel (10-40%) | Copper (55-95%), Zinc (5-45%) |

| Corrosion Resistance | High, excellent in seawater and marine environments | Moderate, susceptible to dezincification in marine conditions |

| Strength | Good tensile strength, superior to brass | Moderate tensile strength |

| Malleability | Lower than brass, less ductile | High malleability, easy to form and shape |

| Thermal Conductivity | Lower than brass | Higher thermal conductivity |

| Common Applications | Marine hardware, desalination plants, coinage | Decorative items, plumbing fittings, musical instruments |

| Cost | Higher due to nickel content | Lower, widely available and economical |

Introduction to Copper-Nickel and Brass Alloys

Copper-nickel alloys, composed primarily of copper and nickel with trace elements like iron and manganese, offer exceptional corrosion resistance and thermal stability, making them ideal for marine and industrial applications. Brass alloys, combining copper and zinc, provide excellent machinability and aesthetic appeal with good strength and electrical conductivity, widely used in decorative and mechanical components. Both alloys leverage copper's inherent properties but differ significantly in composition and performance, catering to distinct industrial needs.

Composition Differences: Copper-Nickel vs Brass

Copper-nickel alloys typically contain 60-90% copper with the remainder being nickel, often combined with small amounts of iron and manganese, enhancing corrosion resistance and strength. Brass alloys consist primarily of copper and zinc, with zinc content ranging from 5% to 40%, influencing color, machinability, and corrosion resistance. The absence of nickel in brass results in different mechanical properties and lower resistance to seawater corrosion compared to copper-nickel alloys.

Mechanical Properties Comparison

Copper-nickel alloys exhibit superior corrosion resistance and tensile strength compared to brass alloys, making them ideal for marine and industrial applications. Brass alloys generally offer better machinability and higher electrical conductivity but fall short in wear resistance and hardness relative to copper-nickel alloys. The enhanced mechanical properties of copper-nickel alloys result from their balanced nickel content, which improves durability and thermal stability in demanding environments.

Corrosion Resistance: Alloy Performance

Copper-nickel alloys exhibit superior corrosion resistance compared to brass alloys, particularly in marine environments due to their enhanced resistance to biofouling and stress corrosion cracking. Brass alloys, composed primarily of copper and zinc, tend to be more susceptible to dezincification and galvanic corrosion when exposed to aggressive conditions. The inherent properties of copper-nickel alloys allow for longer service life and reduced maintenance in applications demanding high corrosion resistance.

Applications of Copper-Nickel Alloys

Copper-nickel alloys are widely used in marine engineering due to their excellent corrosion resistance in seawater, making them ideal for shipbuilding, desalination plants, and offshore oil rigs. Their antimicrobial properties also enable applications in medical devices and coinage, while their high thermal conductivity suits heat exchanger and condenser systems. Compared to brass alloys, copper-nickel alloys perform better in harsh environments requiring durability and resistance to biofouling.

Applications of Brass Alloys

Brass alloys, composed primarily of copper and zinc, are widely used in applications requiring excellent machinability and corrosion resistance, such as plumbing fittings, musical instruments, and decorative hardware. Their antimicrobial properties make them ideal for medical tools and door handles in public spaces. The versatility and durability of brass alloys also lend them to electrical connectors and marine components where reliable conductivity and resistance to saltwater corrosion are essential.

Workability and Fabrication

Copper-nickel alloys exhibit superior corrosion resistance and excellent workability, making them ideal for marine and chemical applications where forming and machining processes require high precision. Brass alloys offer better malleability and ease of fabrication, allowing for intricate shaping and good machinability, favored in decorative and plumbing components. The choice between copper-nickel and brass alloys depends on specific fabrication requirements, balancing mechanical strength, corrosion resistance, and ease of manufacturing.

Cost Analysis: Copper-Nickel vs Brass

Copper-nickel alloys generally incur higher material and production costs compared to brass alloys due to the increased price of nickel and more complex manufacturing processes. Brass alloys, composed primarily of copper and zinc, offer a more cost-effective solution for applications requiring moderate strength and corrosion resistance, benefiting from lower raw material costs and simpler fabrication. Cost analysis must consider not only initial material expenses but also long-term performance benefits and maintenance savings, where copper-nickel alloys excel in harsh environments, potentially offsetting their higher upfront cost.

Environmental and Health Considerations

Copper-nickel alloys exhibit superior corrosion resistance in marine environments, reducing the need for frequent replacements and minimizing environmental waste compared to brass alloys. Brass alloys often contain lead as a machinability additive, posing potential health risks due to lead leaching, whereas copper-nickel alloys typically avoid harmful toxins. The sustainable lifecycle and lower toxicity profile of copper-nickel alloys make them preferable for applications requiring environmental and human health safety.

Choosing the Right Alloy for Your Needs

Copper-nickel alloys offer superior corrosion resistance and excellent strength in marine and chemical environments, making them ideal for applications requiring durability and low maintenance. Brass alloys provide enhanced machinability and electrical conductivity, suited for decorative, plumbing, and electrical components where workability and aesthetic are priorities. Selecting between copper-nickel and brass depends on balancing factors such as environmental exposure, mechanical properties, and specific application requirements.

Copper-nickel alloy vs Brass alloy Infographic

materialdif.com

materialdif.com