Inconel and Hastelloy are both high-performance alloys renowned for their exceptional corrosion resistance and heat tolerance in extreme environments. Inconel, primarily nickel-chromium-based, excels in oxidation resistance at high temperatures, making it ideal for aerospace and chemical processing applications. Hastelloy, rich in nickel and molybdenum, offers superior resistance to aggressive chemical corrosion, especially in acidic and chloride-rich environments, commonly used in nuclear reactors and chemical plants.

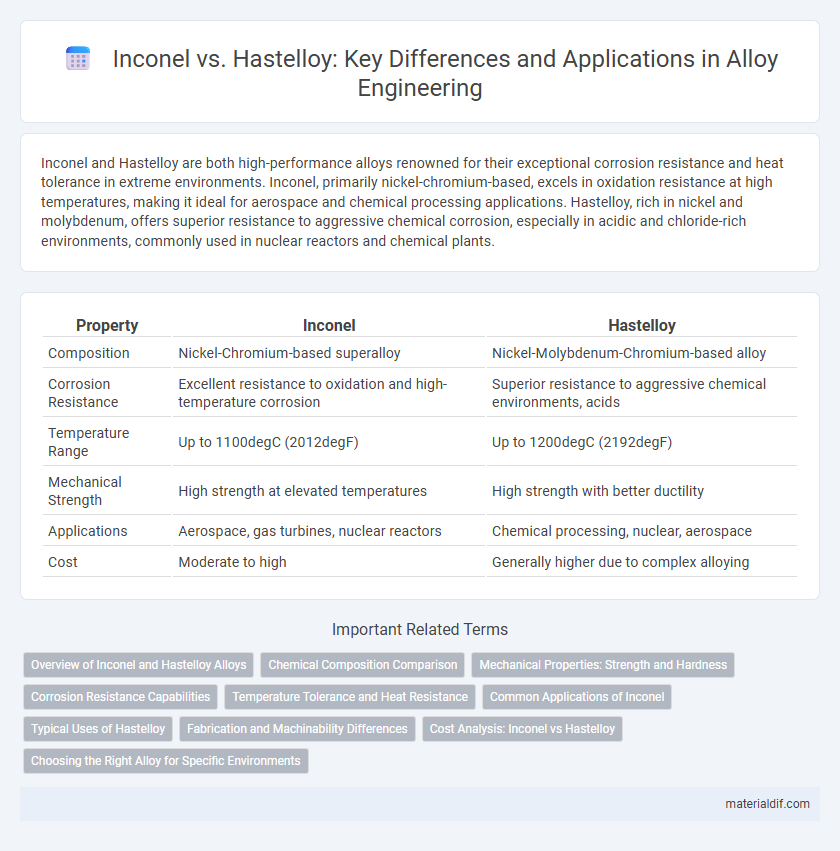

Table of Comparison

| Property | Inconel | Hastelloy |

|---|---|---|

| Composition | Nickel-Chromium-based superalloy | Nickel-Molybdenum-Chromium-based alloy |

| Corrosion Resistance | Excellent resistance to oxidation and high-temperature corrosion | Superior resistance to aggressive chemical environments, acids |

| Temperature Range | Up to 1100degC (2012degF) | Up to 1200degC (2192degF) |

| Mechanical Strength | High strength at elevated temperatures | High strength with better ductility |

| Applications | Aerospace, gas turbines, nuclear reactors | Chemical processing, nuclear, aerospace |

| Cost | Moderate to high | Generally higher due to complex alloying |

Overview of Inconel and Hastelloy Alloys

Inconel alloys are nickel-chromium-based superalloys known for exceptional resistance to oxidation and high-temperature strength, commonly used in aerospace and chemical processing industries. Hastelloy alloys, primarily composed of nickel and molybdenum, exhibit superior corrosion resistance in harsh chemical environments, making them ideal for applications involving acids and extreme conditions. Both Inconel and Hastelloy serve critical roles in high-performance environments, with Inconel favored for oxidation resistance and Hastelloy for aggressive chemical corrosion protection.

Chemical Composition Comparison

Inconel primarily consists of nickel (50-72%), chromium (14-23%), and iron, with minor amounts of molybdenum and copper to enhance corrosion and oxidation resistance. Hastelloy features a higher proportion of molybdenum (up to 16%), nickel (30-65%), and chromium (7-22%), which significantly improves its resistance to aggressive chemical environments and high-temperature strength. The distinct chemical compositions make Inconel suitable for oxidation-resistant applications, while Hastelloy excels in handling highly corrosive chemicals and acid exposure.

Mechanical Properties: Strength and Hardness

Inconel alloys exhibit exceptional tensile strength and hardness, maintaining structural integrity at high temperatures up to 980degC, making them ideal for extreme thermal environments. Hastelloy offers superior corrosion resistance combined with high strength and hardness, particularly in chemical processing applications, and retains its mechanical properties in highly oxidizing and reducing environments at temperatures reaching 870degC. Both alloys demonstrate excellent creep resistance, but Inconel typically provides higher tensile strength, while Hastelloy excels in hardness under chemically aggressive conditions.

Corrosion Resistance Capabilities

Inconel exhibits excellent corrosion resistance in high-temperature and oxidative environments, making it ideal for aerospace and chemical processing applications. Hastelloy offers superior resistance to a wide range of aggressive chemicals, including strong acids and oxidizers, excelling in environments involving hydrochloric and sulfuric acids. Both alloys demonstrate exceptional corrosion resistance, but Hastelloy outperforms Inconel in highly acidic and reducing conditions.

Temperature Tolerance and Heat Resistance

Inconel alloys excel in temperature tolerance, maintaining strength and oxidation resistance up to approximately 1,000degC (1,832degF), making them ideal for high-temperature aerospace and gas turbine applications. Hastelloy offers superior heat resistance in highly corrosive environments, withstanding temperatures up to around 1,150degC (2,102degF) while resisting oxidation and chemical attack, commonly used in chemical processing industries. The choice between Inconel and Hastelloy depends on specific temperature ranges and environmental conditions, balancing thermal stability and corrosion resistance.

Common Applications of Inconel

Inconel alloys are widely used in aerospace, chemical processing, and power generation industries due to their exceptional corrosion resistance and high-temperature strength. Common applications include turbine blades, heat exchangers, and nuclear reactors where they withstand extreme environments. The alloy's ability to maintain mechanical integrity under oxidative and thermal stress makes it a preferred choice for demanding industrial conditions.

Typical Uses of Hastelloy

Hastelloy is widely used in chemical processing equipment due to its exceptional resistance to corrosion in highly oxidizing and reducing environments, particularly in reactors, heat exchangers, and pressure vessels. Its ability to withstand extreme temperatures and aggressive chemicals makes it ideal for aerospace, nuclear reactors, and marine applications. Compared to Inconel, which excels in high-temperature oxidation, Hastelloy's superior corrosion resistance in harsh chemical environments defines its typical industrial uses.

Fabrication and Machinability Differences

Inconel alloys exhibit superior oxidation resistance and high-temperature strength, making them more challenging to machine due to their hardness and tendency to work-harden. Hastelloy, primarily composed of nickel-molybdenum, offers better corrosion resistance and is generally easier to fabricate with conventional machining techniques, although it requires careful control of heat input during welding to prevent distortion. Both alloys demand specialized tooling and coolant strategies, yet Inconel's intricate microstructure often leads to increased tool wear compared to Hastelloy during fabrication.

Cost Analysis: Inconel vs Hastelloy

Inconel alloys generally present a lower initial purchase cost compared to Hastelloy, making them more cost-effective for applications with a moderate budget. Hastelloy, known for superior corrosion resistance and high-temperature performance, often incurs higher material and fabrication costs, which can impact overall project expenses. Evaluating lifecycle costs including maintenance, repair, and replacement is crucial, as Hastelloy may offer better long-term value in aggressive environments despite its upfront price.

Choosing the Right Alloy for Specific Environments

Inconel excels in high-temperature oxidation and corrosion resistance, making it ideal for aerospace and power generation applications subjected to extreme heat. Hastelloy offers superior resistance to harsh chemical environments, particularly against strong oxidizers and reducing agents, making it suitable for chemical processing and nuclear reactors. Selecting between these alloys depends on the specific environmental stressors, such as temperature range and chemical exposure, to ensure optimal performance and longevity.

Inconel vs Hastelloy Infographic

materialdif.com

materialdif.com