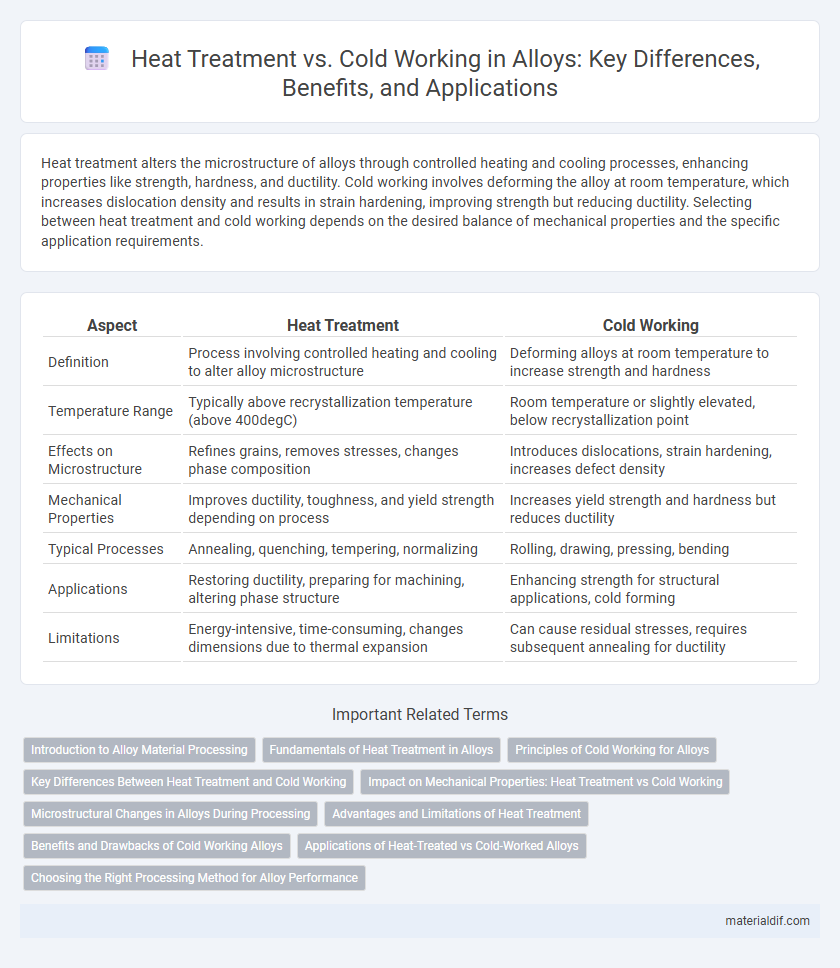

Heat treatment alters the microstructure of alloys through controlled heating and cooling processes, enhancing properties like strength, hardness, and ductility. Cold working involves deforming the alloy at room temperature, which increases dislocation density and results in strain hardening, improving strength but reducing ductility. Selecting between heat treatment and cold working depends on the desired balance of mechanical properties and the specific application requirements.

Table of Comparison

| Aspect | Heat Treatment | Cold Working |

|---|---|---|

| Definition | Process involving controlled heating and cooling to alter alloy microstructure | Deforming alloys at room temperature to increase strength and hardness |

| Temperature Range | Typically above recrystallization temperature (above 400degC) | Room temperature or slightly elevated, below recrystallization point |

| Effects on Microstructure | Refines grains, removes stresses, changes phase composition | Introduces dislocations, strain hardening, increases defect density |

| Mechanical Properties | Improves ductility, toughness, and yield strength depending on process | Increases yield strength and hardness but reduces ductility |

| Typical Processes | Annealing, quenching, tempering, normalizing | Rolling, drawing, pressing, bending |

| Applications | Restoring ductility, preparing for machining, altering phase structure | Enhancing strength for structural applications, cold forming |

| Limitations | Energy-intensive, time-consuming, changes dimensions due to thermal expansion | Can cause residual stresses, requires subsequent annealing for ductility |

Introduction to Alloy Material Processing

Heat treatment modifies alloy microstructures through controlled heating and cooling cycles, enhancing properties such as hardness, strength, and corrosion resistance. Cold working deforms alloys at room temperature, increasing dislocation density and resulting in improved strength and hardness via strain hardening. Understanding the effects of heat treatment and cold working is essential for optimizing alloy performance in material processing applications.

Fundamentals of Heat Treatment in Alloys

Heat treatment in alloys fundamentally involves controlled heating and cooling processes to alter microstructure, enhancing mechanical properties such as strength, hardness, and ductility. Key techniques include annealing, quenching, and tempering, each modifying phase transformations to tailor characteristics for specific applications. Understanding diffusion, nucleation, and phase diagrams is essential to optimize heat treatment for desired alloy performance.

Principles of Cold Working for Alloys

Cold working of alloys involves plastic deformation at temperatures below the recrystallization point, enhancing strength through strain hardening while maintaining dimensional accuracy. This process increases dislocation density within the metal's crystal structure, which impedes further movement of dislocations and thereby elevates yield strength and hardness. Unlike heat treatment, cold working does not alter the alloy's microstructure via phase transformations but relies on mechanical deformation to improve mechanical properties.

Key Differences Between Heat Treatment and Cold Working

Heat treatment alters an alloy's microstructure through controlled heating and cooling cycles to improve hardness, strength, and ductility, while cold working involves deforming the metal at room temperature to enhance strength via strain hardening. Heat treatment processes like annealing, quenching, and tempering modify internal grain structures without changing the metal's shape, whereas cold working produces increased dislocation density, resulting in work hardening and dimensional changes. The choice between heat treatment and cold working depends on desired mechanical properties, as heat treatment can restore ductility lost during cold working, which typically reduces ductility but increases tensile strength.

Impact on Mechanical Properties: Heat Treatment vs Cold Working

Heat treatment alters alloy microstructure through processes like annealing, quenching, and tempering, significantly enhancing mechanical properties such as hardness, tensile strength, and ductility. Cold working increases strength and hardness by inducing strain hardening and dislocation density, but it reduces ductility and can introduce residual stresses. Comparing the two, heat treatment offers controlled modification of mechanical properties with improved toughness, while cold working primarily boosts strength at the expense of flexibility and corrosion resistance.

Microstructural Changes in Alloys During Processing

Heat treatment alters alloy microstructures by promoting phase transformations, recrystallization, and grain growth, resulting in refined grain sizes and enhanced mechanical properties. Cold working induces strain hardening through dislocation density increase and deformation substructures, maintaining distorted grains without phase changes. The combination of both processes tailors alloy strength and ductility by balancing microstructural refinement and strain-induced defects.

Advantages and Limitations of Heat Treatment

Heat treatment enhances alloy properties by improving hardness, strength, and corrosion resistance through processes like annealing, quenching, and tempering. It allows precise control over microstructure modifications, enabling tailored mechanical performance for specific applications. Limitations include potential distortion, residual stresses, and the inability to significantly increase strength beyond certain alloy composition thresholds compared to cold working.

Benefits and Drawbacks of Cold Working Alloys

Cold working alloys significantly enhances their strength and hardness through strain hardening, improving wear resistance without altering the alloy's chemical composition. This process can lead to increased tensile strength and fatigue resistance, but it also introduces residual stresses and may reduce ductility, making the material more susceptible to cracking under certain conditions. Cold working is ideal for applications requiring precise dimensional control and improved mechanical properties without the need for subsequent heat treatment.

Applications of Heat-Treated vs Cold-Worked Alloys

Heat-treated alloys are commonly used in aerospace components, automotive parts, and structural applications where enhanced strength, hardness, and wear resistance are critical. Cold-worked alloys find applications in manufacturing springs, wires, and sheet metal products requiring improved toughness, precise dimensional control, and increased yield strength without altering the material's microstructure. Selecting heat treatment or cold working depends on specific performance requirements such as fatigue resistance, machinability, and corrosion resistance in alloys like aluminum, steel, and titanium.

Choosing the Right Processing Method for Alloy Performance

Heat treatment enhances alloy performance by altering microstructure through controlled heating and cooling cycles, improving hardness, strength, and ductility. Cold working increases strength and hardness by plastic deformation at ambient temperatures, refining grain size and inducing strain hardening without altering chemical composition. Selecting between heat treatment and cold working depends on desired mechanical properties, alloy composition, and final application requirements to optimize performance and durability.

Heat Treatment vs Cold Working Infographic

materialdif.com

materialdif.com