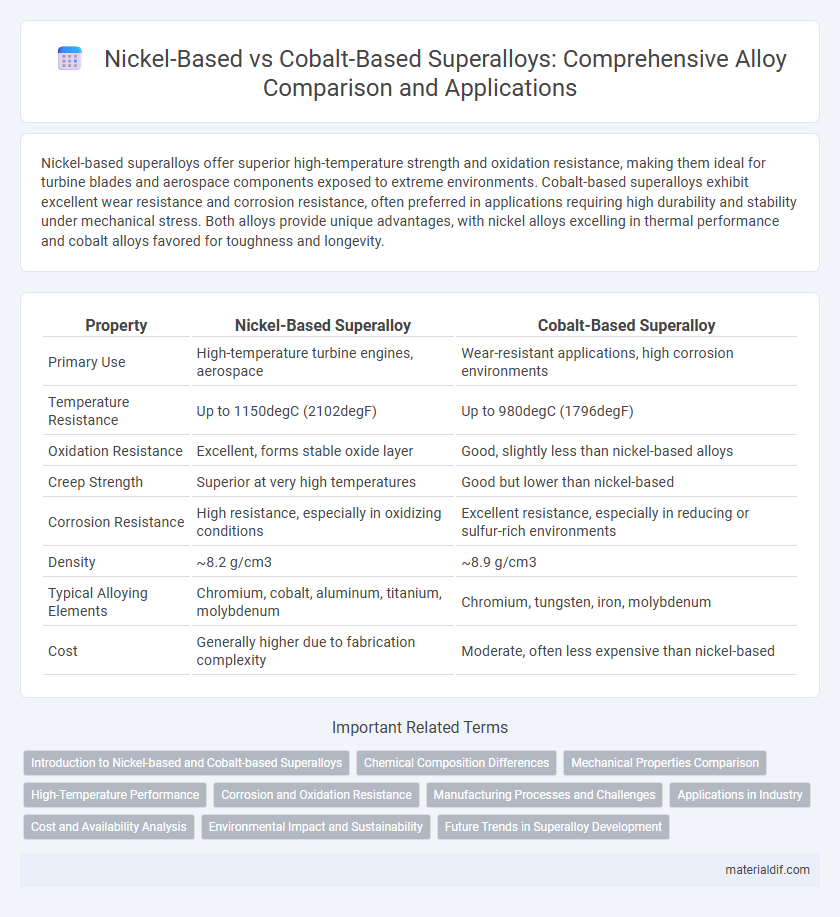

Nickel-based superalloys offer superior high-temperature strength and oxidation resistance, making them ideal for turbine blades and aerospace components exposed to extreme environments. Cobalt-based superalloys exhibit excellent wear resistance and corrosion resistance, often preferred in applications requiring high durability and stability under mechanical stress. Both alloys provide unique advantages, with nickel alloys excelling in thermal performance and cobalt alloys favored for toughness and longevity.

Table of Comparison

| Property | Nickel-Based Superalloy | Cobalt-Based Superalloy |

|---|---|---|

| Primary Use | High-temperature turbine engines, aerospace | Wear-resistant applications, high corrosion environments |

| Temperature Resistance | Up to 1150degC (2102degF) | Up to 980degC (1796degF) |

| Oxidation Resistance | Excellent, forms stable oxide layer | Good, slightly less than nickel-based alloys |

| Creep Strength | Superior at very high temperatures | Good but lower than nickel-based |

| Corrosion Resistance | High resistance, especially in oxidizing conditions | Excellent resistance, especially in reducing or sulfur-rich environments |

| Density | ~8.2 g/cm3 | ~8.9 g/cm3 |

| Typical Alloying Elements | Chromium, cobalt, aluminum, titanium, molybdenum | Chromium, tungsten, iron, molybdenum |

| Cost | Generally higher due to fabrication complexity | Moderate, often less expensive than nickel-based |

Introduction to Nickel-based and Cobalt-based Superalloys

Nickel-based superalloys are engineered for high-temperature environments, exhibiting exceptional strength, corrosion resistance, and oxidation stability crucial for aerospace and power generation applications. Cobalt-based superalloys provide excellent wear resistance and corrosion protection, often preferred in cutting tools and medical implants due to superior hardness and biocompatibility. Both alloy types leverage unique microstructures and elemental compositions to enhance mechanical properties under extreme operating conditions.

Chemical Composition Differences

Nickel-based superalloys primarily contain nickel, chromium, cobalt, and aluminum, with significant additions of molybdenum, titanium, and tantalum to enhance high-temperature strength and corrosion resistance. Cobalt-based superalloys feature a cobalt matrix supplemented by chromium, tungsten, nickel, and carbon, promoting excellent wear resistance and stability at elevated temperatures. The key chemical composition difference lies in the dominant metal matrix--nickel or cobalt--dictating their respective mechanical properties and oxidation behaviors.

Mechanical Properties Comparison

Nickel-based superalloys exhibit superior high-temperature strength and creep resistance compared to cobalt-based superalloys, making them ideal for turbine blades and jet engine components. Cobalt-based superalloys offer better corrosion and oxidation resistance, with improved fatigue life under cyclic thermal stress. The choice between the two alloys depends on the specific mechanical property demands, such as tensile strength, hardness, and thermal stability required in aerospace and power generation industries.

High-Temperature Performance

Nickel-based superalloys exhibit exceptional high-temperature strength and oxidation resistance at temperatures up to 1100degC, making them ideal for gas turbine blades and jet engines. Cobalt-based superalloys maintain superior hot corrosion resistance and mechanical stability at slightly higher temperatures, around 1150degC, which enhances their durability in extreme environments. The choice between nickel and cobalt superalloys depends on the specific thermal and mechanical stress requirements in advanced aerospace and power generation applications.

Corrosion and Oxidation Resistance

Nickel-based superalloys exhibit superior corrosion and oxidation resistance at high temperatures due to the formation of a stable, protective oxide layer rich in aluminum and chromium. Cobalt-based superalloys, while offering excellent strength and wear resistance, generally show lower oxidation resistance compared to nickel-based counterparts, especially in aggressive oxidizing environments. Advanced nickel-based formulations incorporate elements like tungsten and molybdenum to enhance their resistance to sulfidation and hot corrosion, making them more suitable for extreme aerospace and power generation applications.

Manufacturing Processes and Challenges

Nickel-based superalloys are commonly processed using advanced methods like vacuum induction melting (VIM) and powder metallurgy, enabling precise control over microstructure but facing challenges in grain boundary segregation and cracking. Cobalt-based superalloys often require directional solidification and hot isostatic pressing (HIP) to enhance high-temperature strength, yet they pose difficulties in machining and controlling phase stability during manufacturing. Both alloys demand stringent quality control to manage their complex chemistries and ensure optimal performance in aerospace and power generation turbines.

Applications in Industry

Nickel-based superalloys dominate aerospace and power generation industries due to their exceptional high-temperature strength, oxidation resistance, and corrosion resistance, making them ideal for turbine blades and jet engines. Cobalt-based superalloys are preferred in medical implants and wear-resistant applications because of their excellent corrosion resistance and biocompatibility, combined with superior thermal fatigue resistance. Both alloys play crucial roles in industrial sectors requiring materials that withstand extreme environments and mechanical stress.

Cost and Availability Analysis

Nickel-based superalloys generally exhibit higher availability due to the widespread supply of nickel, making them more cost-effective for large-scale industrial applications. Cobalt-based superalloys, though offering superior high-temperature performance, tend to be costlier and less abundant due to limited cobalt reserves and geopolitical supply risks. The price volatility and strategic sourcing challenges of cobalt increase the overall expense and constraint the accessibility of cobalt-based superalloys compared to nickel-based alternatives.

Environmental Impact and Sustainability

Nickel-based superalloys exhibit superior oxidation and corrosion resistance, leading to longer service life and reduced material waste in high-temperature applications, which supports sustainability efforts. Cobalt-based superalloys offer enhanced toughness and thermal fatigue resistance but rely on cobalt, a metal with significant ethical mining concerns and environmental challenges. Selecting nickel-based superalloys can contribute to lower environmental impact by minimizing resource extraction impacts and improving component longevity in aerospace and energy industries.

Future Trends in Superalloy Development

Nickel-based superalloys continue to dominate aerospace applications due to their exceptional high-temperature strength and oxidation resistance, yet cobalt-based superalloys are gaining traction for their superior thermal conductivity and wear resistance in extreme environments. Emerging trends include the integration of additive manufacturing techniques to optimize the complex microstructures of both nickel- and cobalt-based superalloys, enhancing their performance and reducing production costs. Research is increasingly focused on developing hybrid alloys that combine the benefits of nickel and cobalt matrices to achieve unprecedented mechanical properties and thermal stability for next-generation turbine engines.

Nickel-based superalloy vs Cobalt-based superalloy Infographic

materialdif.com

materialdif.com