Powder metallurgy alloys offer superior microstructural control compared to melt-cast alloys, resulting in enhanced mechanical properties such as increased strength and wear resistance. These alloys typically exhibit finer grain structures and reduced porosity, which improve fatigue performance and dimensional accuracy. Melt-cast alloys, while easier to produce in large volumes, often suffer from segregation and coarser grains, limiting their applications in high-performance environments.

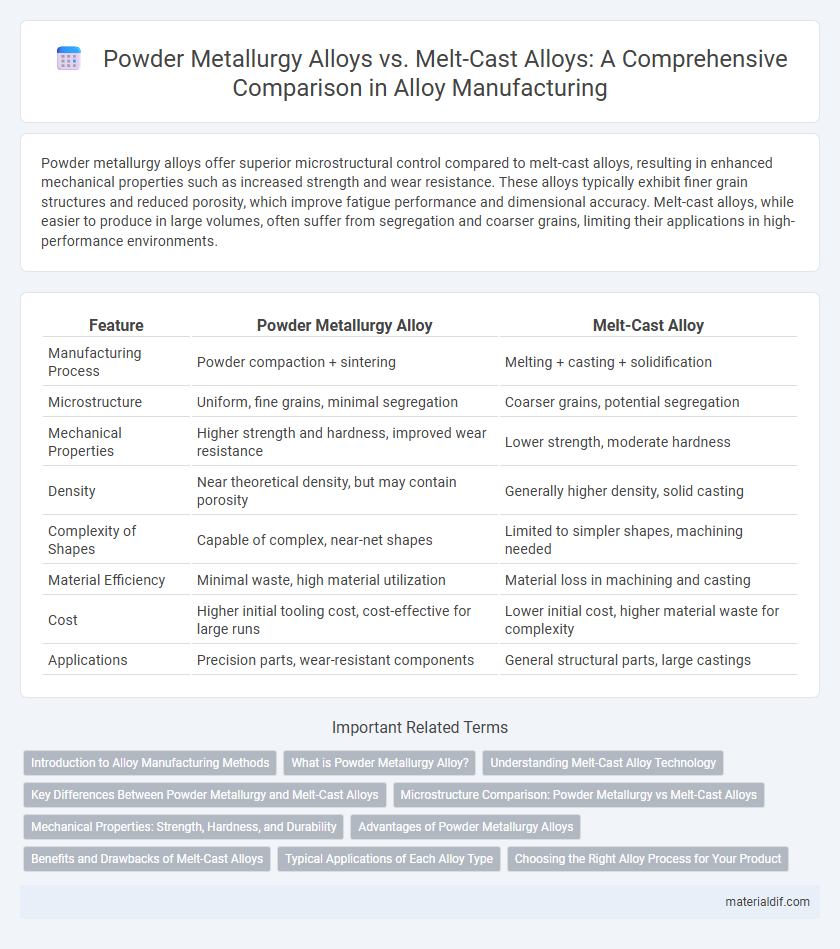

Table of Comparison

| Feature | Powder Metallurgy Alloy | Melt-Cast Alloy |

|---|---|---|

| Manufacturing Process | Powder compaction + sintering | Melting + casting + solidification |

| Microstructure | Uniform, fine grains, minimal segregation | Coarser grains, potential segregation |

| Mechanical Properties | Higher strength and hardness, improved wear resistance | Lower strength, moderate hardness |

| Density | Near theoretical density, but may contain porosity | Generally higher density, solid casting |

| Complexity of Shapes | Capable of complex, near-net shapes | Limited to simpler shapes, machining needed |

| Material Efficiency | Minimal waste, high material utilization | Material loss in machining and casting |

| Cost | Higher initial tooling cost, cost-effective for large runs | Lower initial cost, higher material waste for complexity |

| Applications | Precision parts, wear-resistant components | General structural parts, large castings |

Introduction to Alloy Manufacturing Methods

Powder metallurgy alloy manufacturing involves pressing and sintering metal powders, resulting in precise control over microstructure and alloy composition, which enhances uniformity and mechanical properties. Melt-cast alloy production relies on melting and solidifying metals, offering advantages in large-scale production but often leading to coarser grain structures and less compositional homogeneity. These manufacturing methods directly influence alloy characteristics, such as density, strength, and wear resistance, making method selection critical for specific engineering applications.

What is Powder Metallurgy Alloy?

Powder metallurgy alloy consists of metal powders compacted and sintered to form solid parts with controlled microstructure and enhanced mechanical properties. This process allows for precise composition control, reduced material waste, and the ability to produce complex shapes not achievable through melt casting. Powder metallurgy alloys typically exhibit improved wear resistance and uniformity compared to melt-cast alloys.

Understanding Melt-Cast Alloy Technology

Melt-cast alloy technology involves melting raw materials to form a homogeneous liquid that solidifies into a uniform microstructure, enhancing mechanical properties and corrosion resistance. Unlike powder metallurgy alloys, which use compacted powders sintered at high temperatures, melt-casting allows for larger component sizes and complex shapes with fewer internal defects. This method is particularly advantageous for alloys requiring improved fluidity and fine grain structure control, optimizing performance in aerospace and automotive applications.

Key Differences Between Powder Metallurgy and Melt-Cast Alloys

Powder metallurgy alloys exhibit superior microstructural control and homogeneity compared to melt-cast alloys, resulting in enhanced mechanical properties and reduced porosity. Melt-cast alloys often face challenges with segregation and grain growth during solidification, which can compromise their strength and toughness. Powder metallurgy enables precise composition control and complex shapes with minimal material waste, while melt-cast processes are generally faster but less capable of producing fine microstructures.

Microstructure Comparison: Powder Metallurgy vs Melt-Cast Alloys

Powder metallurgy alloys exhibit a fine, uniform microstructure with minimized segregation and porosity due to controlled particle consolidation and sintering processes. Melt-cast alloys typically display coarser grains and microsegregation resulting from solidification cooling rates and solute redistribution. This microstructural difference leads to enhanced mechanical properties and isotropy in powder metallurgy alloys compared to melt-cast counterparts.

Mechanical Properties: Strength, Hardness, and Durability

Powder metallurgy alloys exhibit superior mechanical properties compared to melt-cast alloys, including higher tensile strength and enhanced hardness due to their fine, uniform microstructure produced by controlled powder compaction and sintering. These alloys demonstrate improved fatigue resistance and wear durability, making them ideal for high-performance engineering applications where material longevity is critical. Melt-cast alloys typically show coarser grain sizes and lower homogeneity, leading to reduced mechanical robustness and increased susceptibility to defects.

Advantages of Powder Metallurgy Alloys

Powder metallurgy alloys offer superior microstructural uniformity and enhanced mechanical properties compared to melt-cast alloys, resulting in higher strength and improved wear resistance. These alloys enable precise control over composition and porosity, facilitating the production of complex shapes with minimal machining and material waste. Their fine-grained structure also supports better thermal stability and fatigue performance, making them ideal for high-performance engineering applications.

Benefits and Drawbacks of Melt-Cast Alloys

Melt-cast alloys offer benefits such as cost-effective production, uniform composition, and suitability for complex shapes, making them ideal for mass manufacturing. However, their drawbacks include potential porosity, lower mechanical strength compared to powder metallurgy alloys, and limited microstructural control during solidification. These factors affect the alloy's performance in high-stress and precision applications.

Typical Applications of Each Alloy Type

Powder metallurgy alloys are commonly used in automotive components, aerospace parts, and cutting tools due to their superior mechanical properties and precise microstructure control. Melt-cast alloys are typically applied in large-scale manufacturing of engine blocks, turbines, and structural components where cost-effectiveness and casting complexity are critical. Each alloy type offers distinct benefits aligning with specific industrial demands such as wear resistance for powder metallurgy alloys and high-volume production for melt-cast alloys.

Choosing the Right Alloy Process for Your Product

Powder metallurgy alloys offer superior microstructural control and enhanced mechanical properties, making them ideal for high-performance applications requiring precision and uniformity. Melt-cast alloys provide cost-effective production with simpler processing for large-scale manufacturing but may exhibit coarser grain structures and less homogeneity. Evaluating factors such as application demands, mechanical property requirements, and production volume is crucial when selecting between powder metallurgy and melt-cast alloy processes.

Powder Metallurgy Alloy vs Melt-Cast Alloy Infographic

materialdif.com

materialdif.com