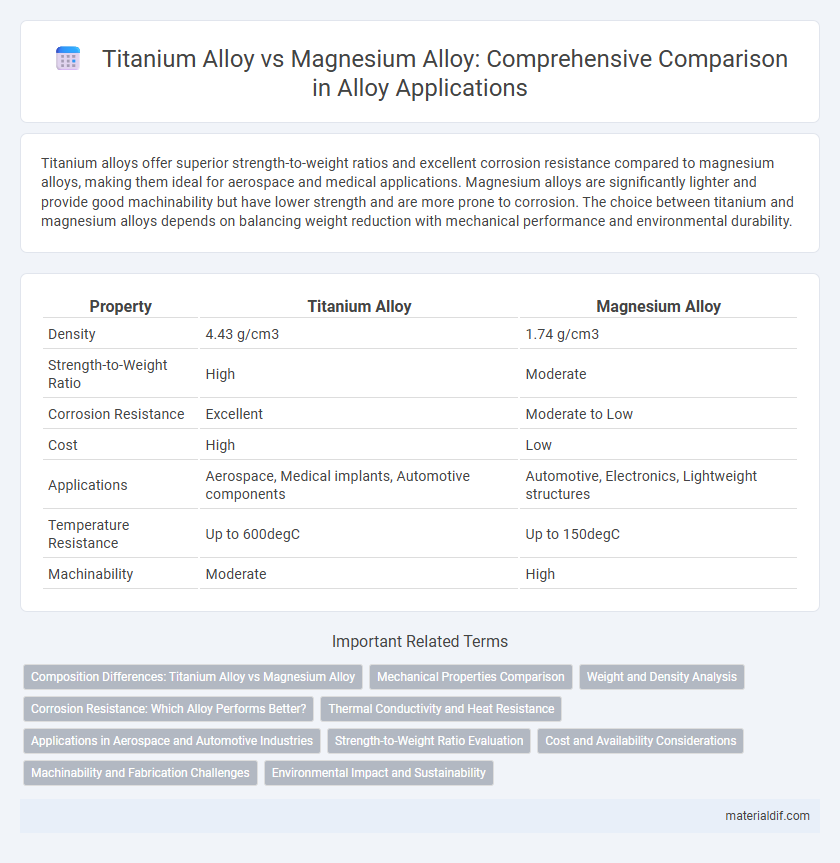

Titanium alloys offer superior strength-to-weight ratios and excellent corrosion resistance compared to magnesium alloys, making them ideal for aerospace and medical applications. Magnesium alloys are significantly lighter and provide good machinability but have lower strength and are more prone to corrosion. The choice between titanium and magnesium alloys depends on balancing weight reduction with mechanical performance and environmental durability.

Table of Comparison

| Property | Titanium Alloy | Magnesium Alloy |

|---|---|---|

| Density | 4.43 g/cm3 | 1.74 g/cm3 |

| Strength-to-Weight Ratio | High | Moderate |

| Corrosion Resistance | Excellent | Moderate to Low |

| Cost | High | Low |

| Applications | Aerospace, Medical implants, Automotive components | Automotive, Electronics, Lightweight structures |

| Temperature Resistance | Up to 600degC | Up to 150degC |

| Machinability | Moderate | High |

Composition Differences: Titanium Alloy vs Magnesium Alloy

Titanium alloys primarily consist of titanium mixed with elements like aluminum, vanadium, and molybdenum, offering superior strength and corrosion resistance. Magnesium alloys combine magnesium with aluminum, zinc, and manganese, emphasizing lightweight properties and good machinability. The distinct elemental compositions result in varied mechanical characteristics and applications, with titanium alloys typically favored for high-strength and high-temperature uses, while magnesium alloys are preferred for weight-sensitive components.

Mechanical Properties Comparison

Titanium alloys exhibit superior strength-to-weight ratios and higher tensile strength compared to magnesium alloys, making them ideal for aerospace and high-performance engineering applications. Magnesium alloys offer lower density and improved machinability but generally possess lower fatigue resistance and reduced corrosion resistance. Mechanical properties such as yield strength in titanium alloys typically range from 800 to 1,200 MPa, while magnesium alloys generally fall between 150 to 350 MPa.

Weight and Density Analysis

Titanium alloy has a density of approximately 4.5 g/cm3, making it significantly heavier than magnesium alloy, which has a density around 1.74 g/cm3. The low density of magnesium alloys results in superior weight savings, ideal for applications demanding lightweight materials such as aerospace and automotive industries. Despite magnesium's weight advantage, titanium alloys offer higher strength-to-weight ratios, balancing density concerns with mechanical performance.

Corrosion Resistance: Which Alloy Performs Better?

Titanium alloys exhibit superior corrosion resistance compared to magnesium alloys due to the formation of a stable, protective oxide layer that effectively prevents surface degradation in harsh environments. Magnesium alloys, while lightweight and strong, are more prone to corrosion, especially in saline or humid conditions, necessitating protective coatings or treatments for extended durability. The enhanced corrosion resistance of titanium alloys makes them ideal for aerospace, marine, and biomedical applications where material longevity and integrity are critical.

Thermal Conductivity and Heat Resistance

Titanium alloys exhibit superior heat resistance with melting points around 1668degC, compared to magnesium alloys, which melt near 650degC, making titanium more suitable for high-temperature applications. Magnesium alloys possess higher thermal conductivity, typically between 70-100 W/m*K, facilitating quicker heat dissipation than titanium alloys, generally ranging from 7-10 W/m*K. This balance of titanium's heat tolerance and magnesium's thermal conductivity dictates their selection in aerospace and automotive industries where thermal performance is critical.

Applications in Aerospace and Automotive Industries

Titanium alloys offer superior strength-to-weight ratios and corrosion resistance, making them ideal for aerospace applications such as airframe components and jet engine parts. Magnesium alloys provide excellent lightweight properties and high machinability, favored in automotive industries for engine blocks, transmission cases, and other components requiring weight reduction. Both alloys enhance fuel efficiency and performance by optimizing structural integrity while minimizing overall vehicle or aircraft weight.

Strength-to-Weight Ratio Evaluation

Titanium alloys exhibit a superior strength-to-weight ratio compared to magnesium alloys, making them ideal for applications requiring both high strength and lightweight properties. The tensile strength of titanium alloys often surpasses 900 MPa while maintaining a density around 4.5 g/cm3, whereas magnesium alloys have lower tensile strengths near 250-350 MPa with densities approximately 1.74 g/cm3. This combination results in titanium alloys offering enhanced structural performance and durability in aerospace and automotive industries where weight reduction is critical.

Cost and Availability Considerations

Titanium alloys typically incur higher costs due to complex extraction and processing methods, contrasting with magnesium alloys, which offer more economical production and widespread availability. The abundance of magnesium in the earth's crust and simpler refining processes contribute to its cost-effectiveness compared to titanium. Budget constraints and supply chain factors make magnesium alloys preferable for large-scale manufacturing requiring lightweight materials.

Machinability and Fabrication Challenges

Titanium alloys exhibit superior machinability due to their high strength-to-weight ratio and excellent corrosion resistance, though they require specialized tooling to manage heat buildup and tool wear. Magnesium alloys offer easier machinability with lower cutting forces and faster material removal rates but pose fabrication challenges like susceptibility to ignition and oxidation during machining. Both alloys demand precise control of processing parameters to optimize component quality and mitigate difficulties in fabrication.

Environmental Impact and Sustainability

Titanium alloys exhibit superior corrosion resistance and biocompatibility, making them more durable and environmentally sustainable through reduced degradation and longer service life. Magnesium alloys, while lighter and more abundant, pose challenges due to higher corrosion rates and potential environmental hazards during manufacturing and recycling processes. The sustainable advantage of titanium alloys lies in their recyclability and lower environmental footprint compared to magnesium alloys, despite the latter's appeal in weight-sensitive applications.

Titanium alloy vs Magnesium alloy Infographic

materialdif.com

materialdif.com