Alloying involves combining two or more metals at the molecular level to create a new material with enhanced mechanical and chemical properties. Plating, on the other hand, involves coating the surface of a metal with a thin layer of another metal to improve corrosion resistance or aesthetic appearance without altering the core material. Unlike plating, alloying results in a homogeneous material throughout, offering greater strength and durability.

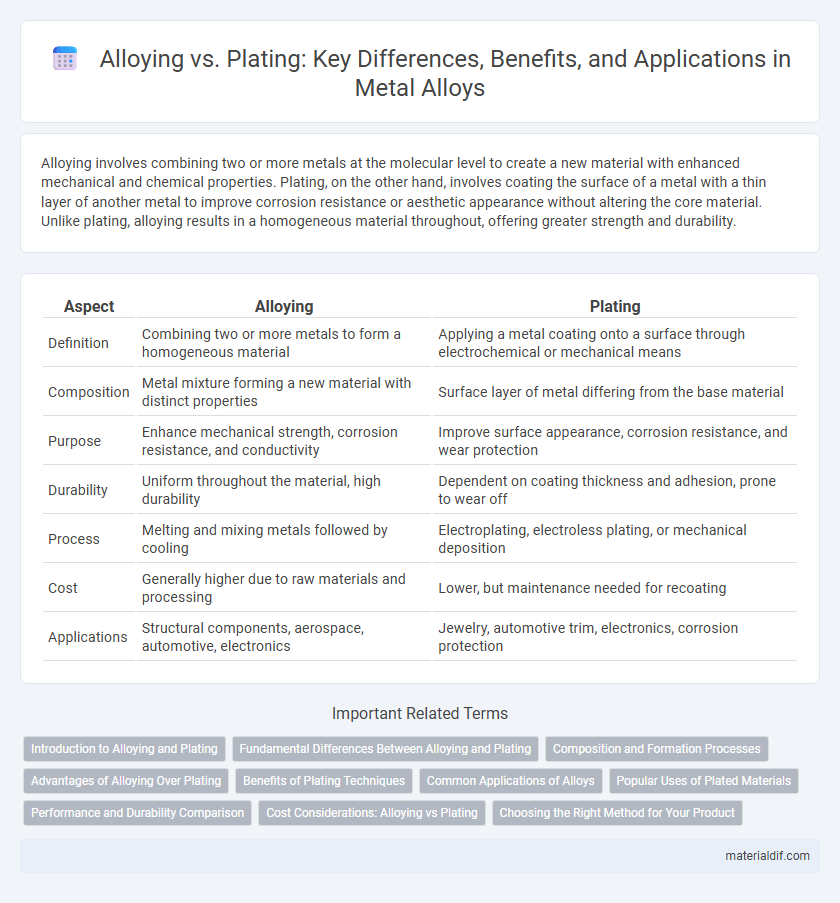

Table of Comparison

| Aspect | Alloying | Plating |

|---|---|---|

| Definition | Combining two or more metals to form a homogeneous material | Applying a metal coating onto a surface through electrochemical or mechanical means |

| Composition | Metal mixture forming a new material with distinct properties | Surface layer of metal differing from the base material |

| Purpose | Enhance mechanical strength, corrosion resistance, and conductivity | Improve surface appearance, corrosion resistance, and wear protection |

| Durability | Uniform throughout the material, high durability | Dependent on coating thickness and adhesion, prone to wear off |

| Process | Melting and mixing metals followed by cooling | Electroplating, electroless plating, or mechanical deposition |

| Cost | Generally higher due to raw materials and processing | Lower, but maintenance needed for recoating |

| Applications | Structural components, aerospace, automotive, electronics | Jewelry, automotive trim, electronics, corrosion protection |

Introduction to Alloying and Plating

Alloying involves combining two or more metals to create a material with enhanced mechanical properties, corrosion resistance, or aesthetic appeal, resulting in a homogeneous mixture with improved durability. Plating, on the other hand, consists of depositing a thin layer of metal onto a surface to enhance wear resistance, prevent corrosion, or improve appearance without altering the bulk properties of the base material. Both processes play crucial roles in metallurgy and manufacturing, with alloying modifying the entire material composition and plating providing surface-specific enhancements.

Fundamental Differences Between Alloying and Plating

Alloying involves combining two or more metals at the atomic level to form a homogeneous solid solution with enhanced mechanical and chemical properties, while plating refers to depositing a thin layer of metal onto a substrate's surface for protection or decoration. Alloying fundamentally alters the bulk material's composition and structure, resulting in improved strength, corrosion resistance, or conductivity. Plating, however, only modifies surface characteristics without changing the underlying metal's core properties.

Composition and Formation Processes

Alloying involves combining two or more metals at the atomic level by melting and solidifying them together, resulting in a uniform composition throughout the material that enhances mechanical properties. Plating, by contrast, is a surface coating technique where a thin layer of metal is deposited onto a substrate through electrochemical or chemical processes, altering only the outer surface composition without affecting the base metal. Alloying forms a new homogeneous material with integrated properties, while plating provides a protective or decorative surface layer without modifying the core structure.

Advantages of Alloying Over Plating

Alloying enhances material properties by integrating elements uniformly, resulting in improved strength, corrosion resistance, and durability compared to plating. Unlike plating, which adds only a surface coating susceptible to wear and damage, alloying ensures consistent characteristics throughout the entire metal. This internal modification reduces maintenance needs and extends the lifespan of components in demanding environments.

Benefits of Plating Techniques

Plating techniques enhance surface properties by providing corrosion resistance, wear protection, and improved aesthetic appeal without altering the alloy's core composition. They allow precise control over layer thickness and composition, optimizing performance for specific applications such as electronics or automotive parts. Plating also reduces material costs by using thin coatings instead of bulk alloy modifications.

Common Applications of Alloys

Alloying involves combining two or more metals to create materials with enhanced mechanical properties, corrosion resistance, and temperature tolerance, commonly seen in automotive engine components, aerospace structures, and construction materials. Plating, on the other hand, primarily adds a thin layer of metal to improve surface hardness, aesthetic appeal, or corrosion protection, typically used in electronics, jewelry, and tooling. Alloys like stainless steel, brass, and bronze dominate applications where durability, strength, and heat resistance are critical, distinguishing them from surface-focused benefits of plating.

Popular Uses of Plated Materials

Plated materials are widely used in electronics for their excellent conductivity and corrosion resistance, making them essential for circuit boards and connectors. In the automotive industry, plating enhances aesthetic appeal and durability of components such as trim and wheels. Jewelry manufacturing relies on plating to provide a high-quality finish and affordable alternatives to solid precious metals.

Performance and Durability Comparison

Alloying enhances metal properties by integrating elements at the molecular level, resulting in improved strength, corrosion resistance, and thermal stability compared to plating, which merely applies a surface layer. Performance benefits of alloys include uniform wear resistance and structural integrity throughout the material, while plating's durability is limited by coating thickness and adhesion quality. Over time, alloys maintain consistent mechanical properties under stress, whereas plated surfaces may degrade through peeling or corrosion, reducing overall lifespan.

Cost Considerations: Alloying vs Plating

Alloying generally involves higher initial material and processing costs due to the blending of base metals and the need for precise temperature control during melting and solidification. Plating tends to be more cost-effective for surface enhancement as it applies a thin layer of metal onto a substrate, reducing the amount of expensive material used. Long-term maintenance costs favor alloying because it offers improved durability and corrosion resistance, whereas plating may require frequent reapplication to maintain protective qualities.

Choosing the Right Method for Your Product

Choosing between alloying and plating depends on the desired material properties and product application. Alloying integrates different metals at the molecular level, enhancing strength, corrosion resistance, and durability, which is ideal for structural components. Plating applies a surface layer for improved appearance, corrosion protection, or conductivity, making it suitable for decorative or electronic products.

Alloying vs Plating Infographic

materialdif.com

materialdif.com