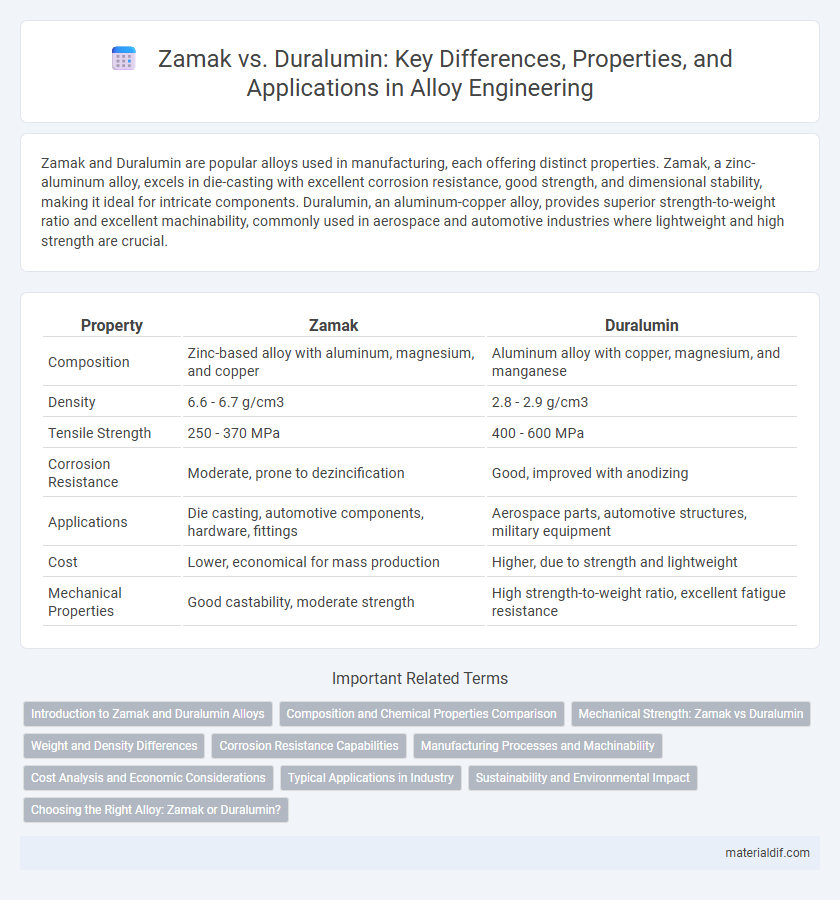

Zamak and Duralumin are popular alloys used in manufacturing, each offering distinct properties. Zamak, a zinc-aluminum alloy, excels in die-casting with excellent corrosion resistance, good strength, and dimensional stability, making it ideal for intricate components. Duralumin, an aluminum-copper alloy, provides superior strength-to-weight ratio and excellent machinability, commonly used in aerospace and automotive industries where lightweight and high strength are crucial.

Table of Comparison

| Property | Zamak | Duralumin |

|---|---|---|

| Composition | Zinc-based alloy with aluminum, magnesium, and copper | Aluminum alloy with copper, magnesium, and manganese |

| Density | 6.6 - 6.7 g/cm3 | 2.8 - 2.9 g/cm3 |

| Tensile Strength | 250 - 370 MPa | 400 - 600 MPa |

| Corrosion Resistance | Moderate, prone to dezincification | Good, improved with anodizing |

| Applications | Die casting, automotive components, hardware, fittings | Aerospace parts, automotive structures, military equipment |

| Cost | Lower, economical for mass production | Higher, due to strength and lightweight |

| Mechanical Properties | Good castability, moderate strength | High strength-to-weight ratio, excellent fatigue resistance |

Introduction to Zamak and Duralumin Alloys

Zamak alloys are primarily composed of zinc, aluminum, magnesium, and copper, known for their excellent casting properties, corrosion resistance, and strength, making them ideal for intricate die-casting applications. Duralumin, an aluminum-copper alloy, is characterized by its lightweight nature, high tensile strength, and good machinability, commonly used in aerospace and automotive industries. Both alloys offer distinct advantages in strength-to-weight ratio and corrosion resistance, with Zamak excelling in detailed castings and Duralumin favored for structural components.

Composition and Chemical Properties Comparison

Zamak is primarily composed of zinc with aluminum, magnesium, and copper, offering excellent corrosion resistance and low melting point suitable for die-casting. Duralumin consists mainly of aluminum alloyed with copper, manganese, and magnesium, providing higher strength and better fatigue resistance while maintaining light weight. Chemically, Zamak exhibits greater resistance to oxidation due to its zinc base, whereas Duralumin's aluminum foundation results in superior mechanical properties but requires protective coatings to prevent corrosion.

Mechanical Strength: Zamak vs Duralumin

Zamak alloys exhibit moderate mechanical strength with tensile strength typically ranging from 280 to 380 MPa, making them suitable for die-casting applications where good castability and corrosion resistance are required. Duralumin, an aluminum-copper alloy, offers significantly higher mechanical strength with tensile strength values commonly between 400 and 550 MPa, attributed to its heat-treatable characteristics and higher hardness. The superior strength-to-weight ratio of Duralumin makes it preferable in aerospace and structural applications demanding enhanced durability and load-bearing capacity over Zamak alloys.

Weight and Density Differences

Zamak, mainly composed of zinc with aluminum and magnesium, has a density of approximately 6.6 to 6.7 g/cm3, making it heavier than Duralumin, an aluminum-copper alloy with a density around 2.8 g/cm3. The significant weight difference means Duralumin is favored in aerospace and automotive industries where lightweight materials improve fuel efficiency and performance. Zamak's higher density grants it superior stability and durability in applications like die casting, but at the cost of added weight compared to Duralumin.

Corrosion Resistance Capabilities

Zamak alloys offer superior corrosion resistance due to their zinc base combined with aluminum and magnesium, forming a protective oxide layer that prevents rust and degradation. Duralumin, primarily composed of aluminum with copper, has moderate corrosion resistance but is more prone to oxidation and requires protective coatings or treatments. Industries seeking longevity in harsh environments often prefer Zamak for its enhanced durability against moisture and chemical exposure.

Manufacturing Processes and Machinability

Zamak alloys offer excellent casting properties due to their low melting points and good fluidity, enabling precise die-casting manufacturing processes. Duralumin, an aluminum-copper alloy, requires more complex forging and heat treatment operations, which result in higher strength but reduce machinability compared to Zamak. Machining Zamak is easier and faster with less tool wear, while Duralumin demands specialized tooling and slower feed rates to manage its higher hardness and strength.

Cost Analysis and Economic Considerations

Zamak alloys, composed primarily of zinc with aluminum, magnesium, and copper, offer lower production costs due to cheaper raw materials and simpler casting processes compared to duralumin, an aluminum-copper alloy known for its higher strength-to-weight ratio. Economic considerations favor zamak in applications with high-volume, low-cost manufacturing demands, while duralumin's higher material and machining costs justify its use in aerospace and automotive industries where durability and weight savings are critical. The cost analysis reveals zamak's affordability in die-casting and corrosion resistance, making it ideal for consumer goods, whereas duralumin's premium price aligns with performance-driven sectors requiring enhanced mechanical properties.

Typical Applications in Industry

Zamak alloys, primarily composed of zinc with aluminum, magnesium, and copper, are extensively used in die casting applications for automotive parts, household hardware, and electrical components due to their excellent casting properties and corrosion resistance. Duralumin, an aluminum-copper alloy, finds typical applications in aerospace and transportation industries where lightweight strength and fatigue resistance are critical, such as aircraft frames, automotive engine components, and structural parts. The choice between Zamak and Duralumin depends on specific industry requirements for mechanical strength, weight, and corrosion resistance.

Sustainability and Environmental Impact

Zamak alloys, primarily composed of zinc with aluminum, magnesium, and copper, offer excellent recyclability due to zinc's abundant natural occurrence and efficient recovery processes, reducing environmental impact significantly. Duralumin, an aluminum-copper alloy, demands higher energy consumption during extraction and recycling, contributing to a larger carbon footprint despite its lightweight strength advantages. Choosing Zamak supports sustainability goals by promoting resource efficiency and minimizing eco-toxic emissions in manufacturing compared to more energy-intensive Duralumin production.

Choosing the Right Alloy: Zamak or Duralumin?

Zamak, a zinc-aluminum alloy, offers excellent corrosion resistance, easy casting, and good dimensional stability, making it ideal for intricate components and decorative items. Duralumin, an aluminum-copper alloy, provides superior strength-to-weight ratio and excellent fatigue resistance, commonly used in aerospace and automotive applications requiring structural integrity. Choosing between Zamak and Duralumin depends on the application's strength requirements, corrosion exposure, and manufacturing processes.

Zamak vs Duralumin Infographic

materialdif.com

materialdif.com