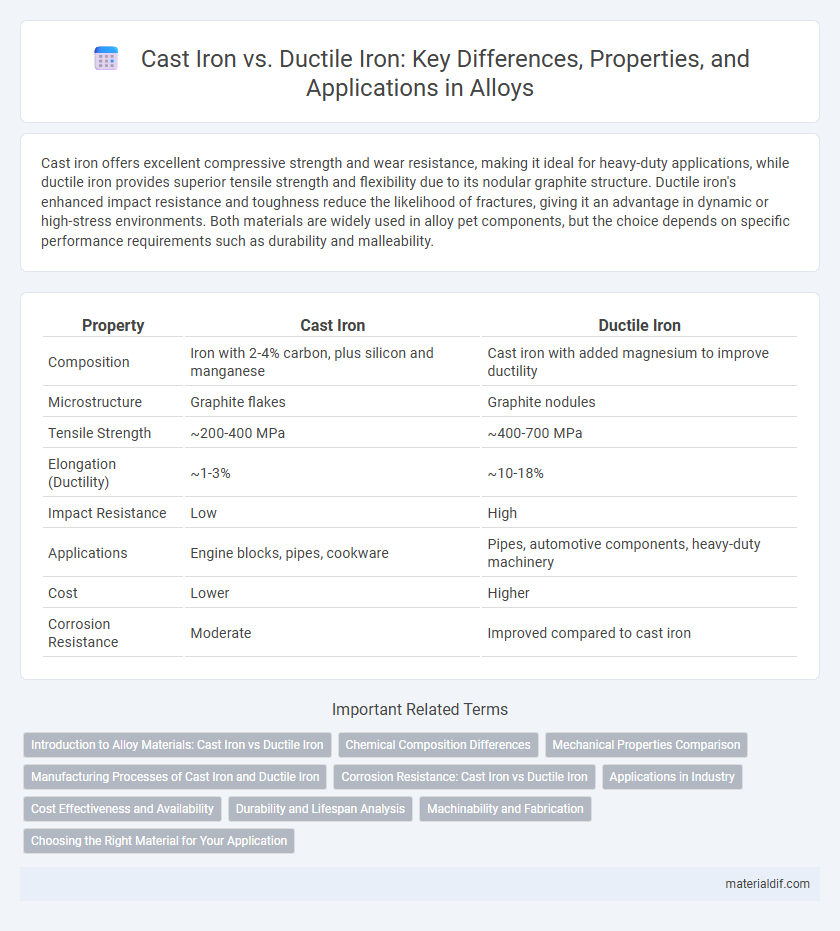

Cast iron offers excellent compressive strength and wear resistance, making it ideal for heavy-duty applications, while ductile iron provides superior tensile strength and flexibility due to its nodular graphite structure. Ductile iron's enhanced impact resistance and toughness reduce the likelihood of fractures, giving it an advantage in dynamic or high-stress environments. Both materials are widely used in alloy pet components, but the choice depends on specific performance requirements such as durability and malleability.

Table of Comparison

| Property | Cast Iron | Ductile Iron |

|---|---|---|

| Composition | Iron with 2-4% carbon, plus silicon and manganese | Cast iron with added magnesium to improve ductility |

| Microstructure | Graphite flakes | Graphite nodules |

| Tensile Strength | ~200-400 MPa | ~400-700 MPa |

| Elongation (Ductility) | ~1-3% | ~10-18% |

| Impact Resistance | Low | High |

| Applications | Engine blocks, pipes, cookware | Pipes, automotive components, heavy-duty machinery |

| Cost | Lower | Higher |

| Corrosion Resistance | Moderate | Improved compared to cast iron |

Introduction to Alloy Materials: Cast Iron vs Ductile Iron

Cast iron is a brittle alloy primarily composed of iron, carbon (2-4%), and silicon, known for its excellent compressive strength and machinability but limited tensile strength. Ductile iron, also called nodular or spheroidal graphite iron, contains similar elements with added magnesium or cerium to improve ductility, making it more resistant to impact and deformation. Both alloys are widely used in automotive and construction industries, with cast iron favored for rigidity and ductile iron preferred for applications requiring toughness and flexibility.

Chemical Composition Differences

Cast iron primarily contains 2.5-4% carbon and 1-3% silicon, which results in a brittle microstructure due to the presence of graphite flakes. Ductile iron differs by adding magnesium (0.03-0.05%) and cerium or other nodulizing agents that transform graphite flakes into spherical nodules, enhancing ductility and impact resistance. The modified chemical composition of ductile iron balances carbon, silicon, and alloying elements to achieve improved mechanical properties compared to traditional cast iron.

Mechanical Properties Comparison

Ductile iron exhibits superior tensile strength, typically ranging from 60,000 to 100,000 psi, compared to cast iron's 20,000 to 60,000 psi, due to its spherical graphite structure enhancing ductility and impact resistance. Cast iron, with higher carbon content and a flake graphite microstructure, offers excellent compressive strength but is brittle and prone to cracking under tensile stress. The enhanced elongation of ductile iron, often 10-20%, significantly surpasses cast iron's low elongation of 1-3%, making ductile iron more suitable for applications requiring toughness and flexibility.

Manufacturing Processes of Cast Iron and Ductile Iron

Cast iron is produced through a traditional sand casting process where molten iron is poured into molds, allowing for easy shaping and solidification with high carbon content that forms graphite flakes. Ductile iron manufacturing involves a similar casting process, but the melt is treated with nodulizing agents like magnesium or cerium to transform graphite flakes into spherical nodules, enhancing tensile strength and ductility. Both processes require precise temperature control during melting and pouring to achieve desired mechanical properties and graphite morphology.

Corrosion Resistance: Cast Iron vs Ductile Iron

Ductile iron exhibits superior corrosion resistance compared to cast iron due to its spheroidal graphite structure, which reduces crack initiation and propagation caused by corrosive environments. Cast iron, with its flake graphite, tends to be more brittle and susceptible to corrosion-related damage, especially in acidic or marine settings. Protective coatings and alloying elements like nickel and chromium further enhance the corrosion resistance of ductile iron in demanding industrial applications.

Applications in Industry

Cast iron is widely used in heavy-duty applications such as engine blocks, pipes, and machinery bases due to its excellent compressive strength and wear resistance. Ductile iron, known for its superior tensile strength and impact resistance, is preferred in automotive components, aerospace parts, and water infrastructure requiring high durability and flexibility. Both alloys offer cost-effective solutions, with ductile iron increasingly favored in dynamic environments demanding improved mechanical performance.

Cost Effectiveness and Availability

Cast iron generally offers lower initial costs due to its widespread availability and simpler manufacturing processes, making it highly cost-effective for large-scale, non-critical applications. Ductile iron, although more expensive, provides superior mechanical properties such as enhanced tensile strength and ductility, which can reduce long-term maintenance and replacement expenses. Availability of cast iron remains broad globally, whereas ductile iron, while growing in supply, may have higher lead times and costs depending on regional foundry capabilities.

Durability and Lifespan Analysis

Ductile iron exhibits superior durability compared to cast iron due to its enhanced tensile strength and impact resistance, resulting from the spherical graphite nodules in its microstructure. This structural difference allows ductile iron to withstand higher mechanical stress and cyclic loading, extending its lifespan significantly in demanding applications such as pipelines and automotive components. Cast iron, characterized by brittle flake graphite, tends to crack under stress and has a shorter service life in dynamic environments where toughness is critical.

Machinability and Fabrication

Cast iron exhibits excellent machinability due to its graphite flake structure, allowing for smooth cutting and shaping during fabrication, but it tends to be more brittle compared to ductile iron. Ductile iron, with its nodular graphite microstructure, offers better ductility and toughness, making it more suitable for complex machining and fabrication processes that require higher strength and flexibility. The choice between cast iron and ductile iron depends on specific application requirements, balancing machinability with the mechanical properties needed for durable fabrication.

Choosing the Right Material for Your Application

Cast iron offers excellent compressive strength and wear resistance, making it ideal for heavy-duty applications such as engine blocks and pipes. Ductile iron provides enhanced ductility and impact resistance due to its nodular graphite structure, suitable for components requiring toughness and flexibility like automotive suspensions and gears. Selecting between cast iron and ductile iron depends on balancing factors such as strength, machinability, and application-specific mechanical demands.

Cast Iron vs Ductile Iron Infographic

materialdif.com

materialdif.com